Visible-light-driven photocatalyst based on mineral composite material and preparation method thereof

A technology of composite materials and catalysts, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low compatibility, difficult recovery, secondary pollution, etc., and achieve enhanced adsorption performance, Enhance effective contact and prevent secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

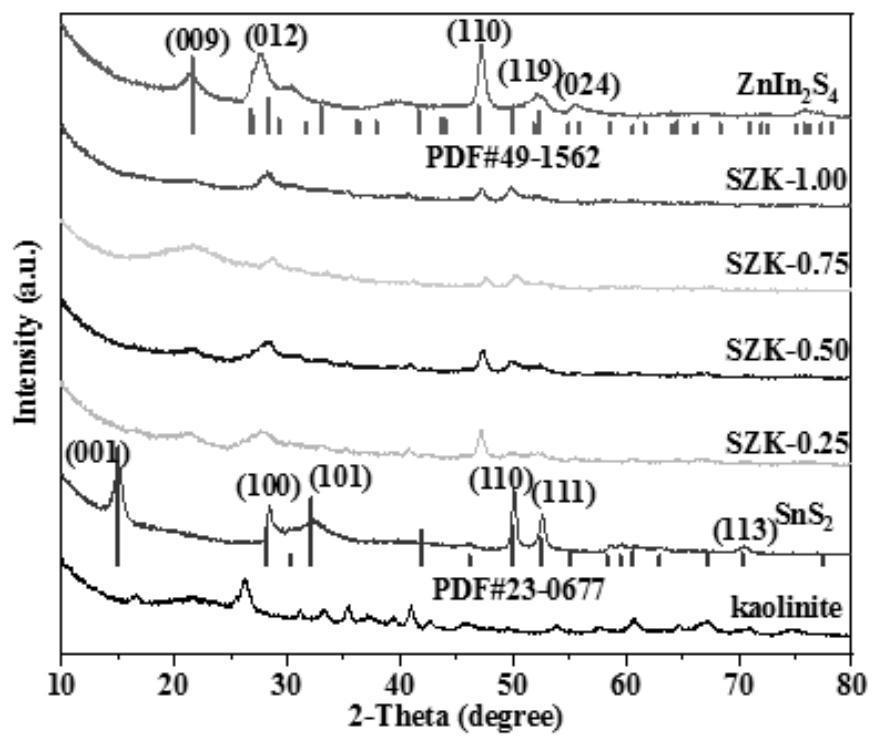

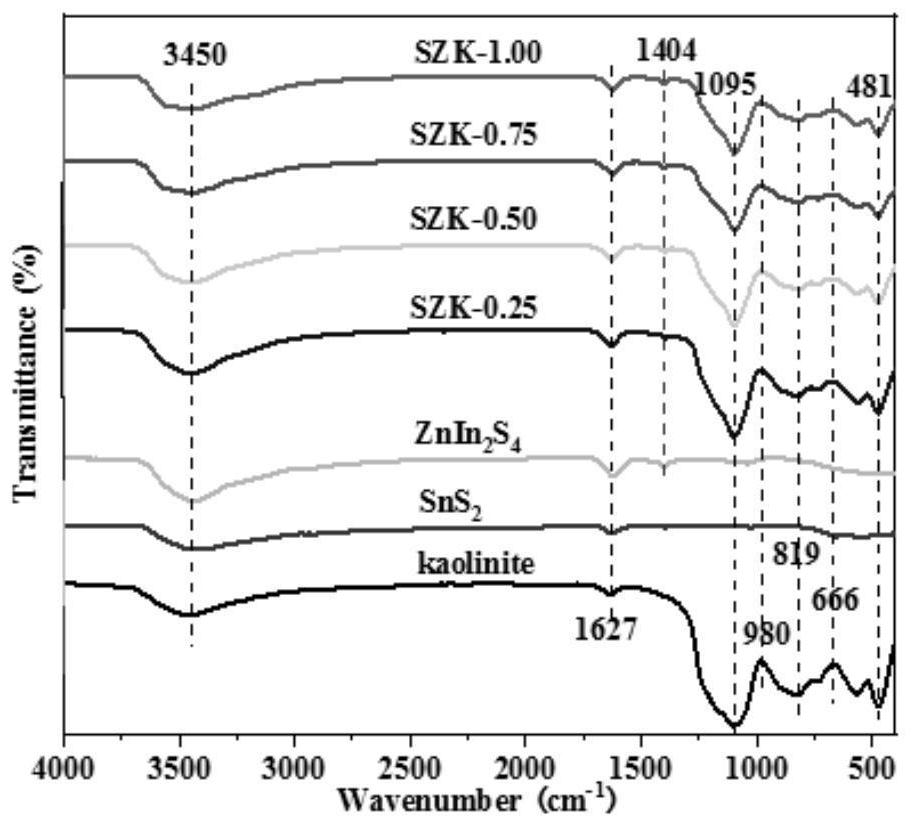

[0031] Embodiment 1: the preparation of SZK-0.25 composite catalyst:

[0032] 1) Weigh 0.18635g Zn(COOCH 3 ) 2 , 0.2029g SnCl 4 ·5H 2 O, 0.5865g InCl 3 4H 2 O was dissolved in deionized water and stirred for 30 minutes to obtain solution C; weigh 0.3875g CH 3 CSNH 2 and 1g of kaolin were dispersed in deionized water, stirred for 30min to obtain solution D, then solution C was added dropwise to solution D, and continuously stirred for 1h to obtain a suspension;

[0033] 2) Transfer the suspension obtained in step 1) to a reaction kettle, and perform a homogeneous hydrothermal reaction at 160° C. for 12 hours;

[0034] 3) Transfer the reactant obtained in step 2) to a centrifuge tube, centrifuge at 9000rpm for 10min, wash with water and ethanol solution several times, and obtain a yellow precipitate;

[0035] 4) Put the obtained yellow precipitate into an oven, dry it at 70°C for 12 hours, and after cooling to room temperature, the obtained yellow powder is SnS 2 / ZnIn ...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is that the compound SnCl is changed 4 ·5H 2 O and CH 3 CSNH 2 The amount of SnCl 4 ·5H 2 O and CH 3 CSNH 2 The masses are 0.4057g and 0.4744g respectively so that the SnS in the final composite photocatalyst 2 with ZnIn 2 S 4 The weight ratio of 0.50:1 product obtained is correspondingly marked as SZK-0.50, and all the other reaction steps are the same.

Embodiment 3

[0040] The difference between embodiment 3 and embodiment 1 is that the compound SnCl is changed 4 ·5H 2 O and CH 3 CSNH 2 The amount of SnCl 4 ·5H 2 O and CH 3 CSNH 2 The masses are 0.6085g and 0.5614g respectively so that the SnS in the final composite photocatalyst 2 with ZnIn 2 S 4 The weight ratio is 0.75:1, and the resulting product is correspondingly marked as SZK-0.75, and the rest of the reaction steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com