Internal burr removal mechanism for straight seam steel pipe

A technology for steel pipes and straight seams, applied in the field of burr removal mechanisms in straight seam steel pipes, can solve problems such as easy corrosion of protrusions at weld seams, reduced service life of steel pipes, and decreased fluid flow rate in pipes, so as to shorten abnormal processing time , Guaranteed performance and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

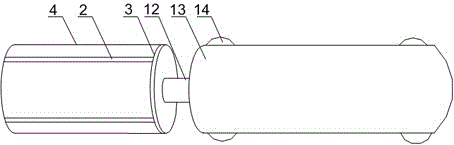

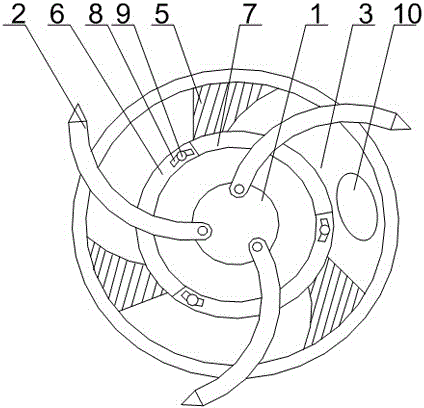

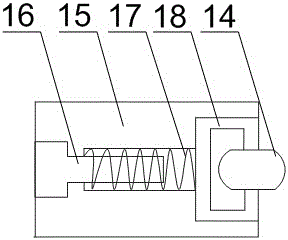

[0021] like figure 1 , figure 2 and image 3 As shown, the external burr cleaning mechanism for welded steel pipes of the present invention includes a support cylinder 13, the end of the support cylinder 13 is connected with an external mandrel, a plurality of rollers 14 are arranged on the support cylinder 13, and the support cylinder 13 A drive motor is arranged inside, and the output end 12 of the drive motor is connected to a tool. The tool includes a central shaft 1, and a plurality of arc-shaped blades 2 are arranged on the central shaft 1. The arc-shaped blades 2 are hinged with the central shaft 1 and The annular array is distributed on the outer wall of the central shaft 1, the upper and lower ends of the central shaft 1 are installed with fixed plates 3 and the arc-shaped blade 2 is arranged between the two fixed plates 3, and also includes a blade angle adjustment set between the arc-shaped blades 2 The blade angle adjustment mechanism includes a connecting rod 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com