Electronic element pin cutting device for carrying out cutting through laser and application method

An electronic component and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as damage to electronic components, impact force of electronic components, and low efficiency, and achieve the effect of avoiding damage and improving cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

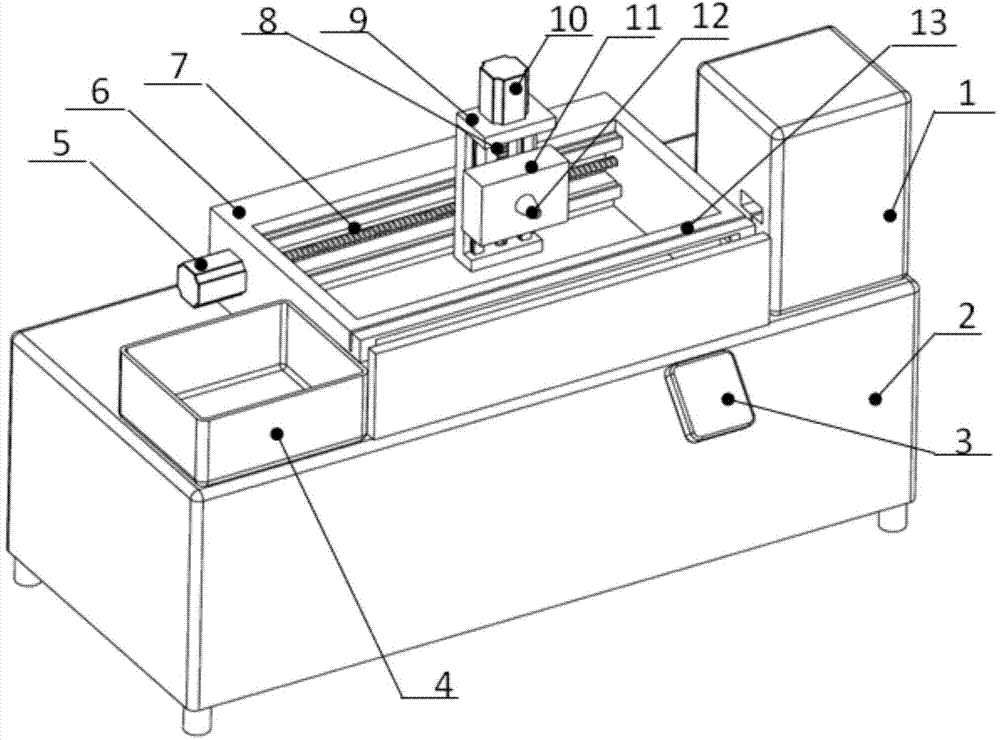

[0023] see figure 1 , the electronic component cutting device for cutting with laser of the present invention comprises a controller, a vibrating material selector 1, a cutting machine main body 6, a laser emitter 12, an X-axis motor assembly and a Z-axis motor assembly, and the X-axis motor assembly Including an X-axis motor 5, an X-axis transmission screw rod 7 and an X-axis moving support 9, the X-axis motor 5 is arranged on the main body 6 of the foot cutting machine, the X-axis motor 5 is connected with the X-axis transmission screw rod 7, and the X-axis transmission wire The rod 7 is passed through the threaded hole of the X-axis moving support 9 and matches with the threaded hole. The main body 6 of the cutting machine is provided with a guide rail that can accommodate the sliding of the X-axis moving support 9. The Z-axis motor assembly includes a Z-axis motor 10. The Z-axis driving screw 8 and the Z-axis moving support 11, the Z-axis motor 10 is arranged on the X-axis...

Embodiment 2

[0031] The present invention also provides a method for using the above-mentioned electronic component cutting device for cutting with a laser, comprising the following steps:

[0032] First put the electronic components to be cut into the vibrating material sorter for sorting, and then the vibrating material sorting machine pushes the sorted electronic components into the slot holes. When the electronic components arranged in the slot holes reach a certain number (arrangement The number of electronic components can be determined according to the needs), and the controller drives the Z-axis motor to move through the control panel setting to drive the laser emitter to move up and down to a suitable height (the height of the laser emitter can be determined according to the cutting height of the pin) , and then turn on the laser transmitter (can be set in the control panel or manually controlled), and at the same time set the controller to drive the X-axis motor through the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com