Two-way adjustable tilt welding roller frame

A roller frame, inclination technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of improving transmission efficiency, high transmission efficiency, and reducing exposed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

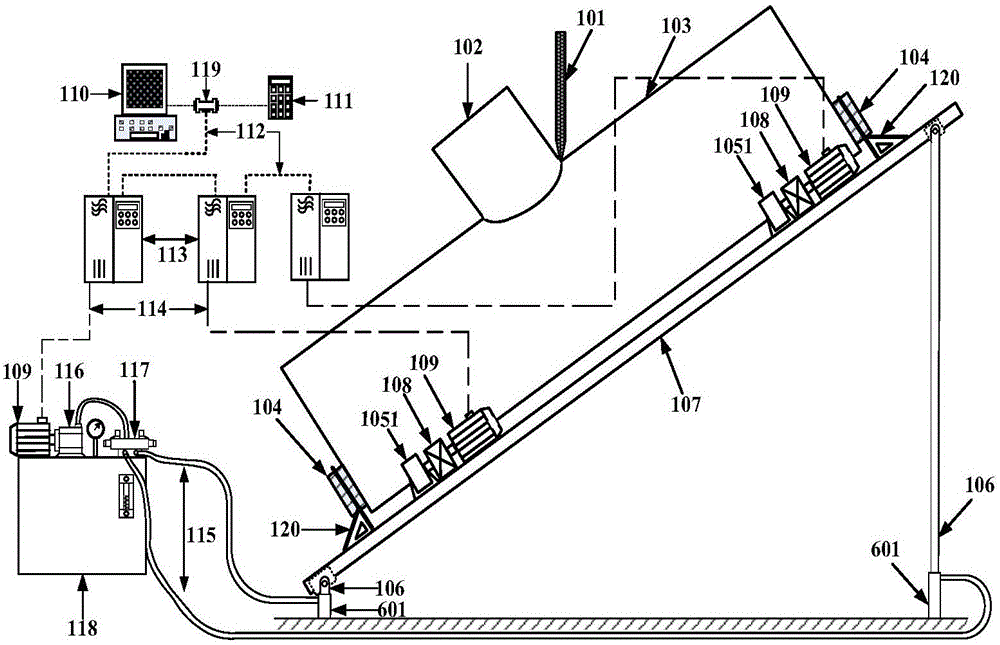

[0040] The present invention is applied to circular seam welding of thick-walled and large-size cylindrical weldments perpendicular to each other, such as figure 1 As shown: when the large weldment 103 and the small weldment 102 adopt 45° groove welding, it can ensure that the welding torch 101 maintains a vertical posture during the whole welding process, thereby ensuring the best welding angle.

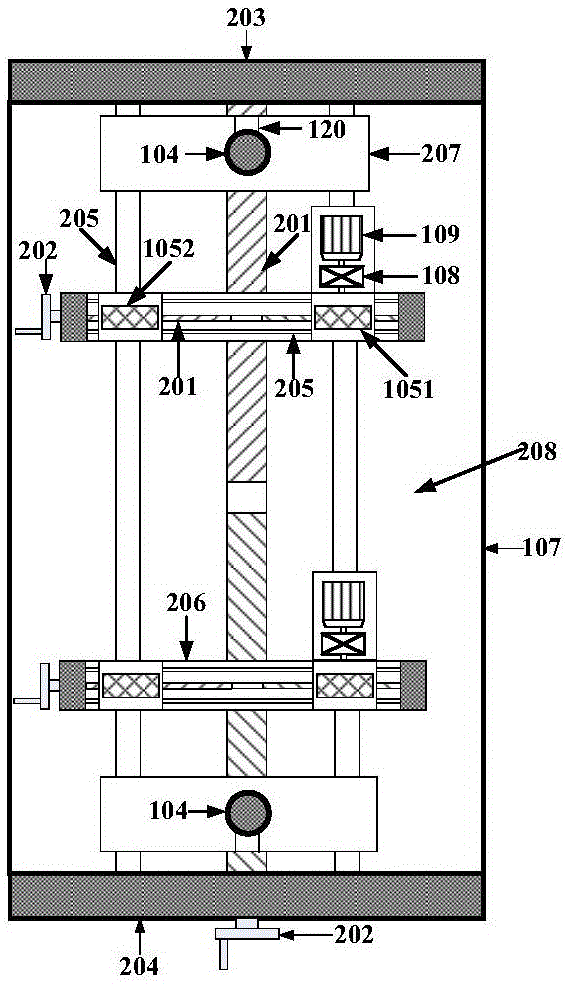

[0041] A two-way adjustable inclination welding roller frame of the present invention is composed of a pitching motion subsystem, a rotating motion subsystem and a central controller.

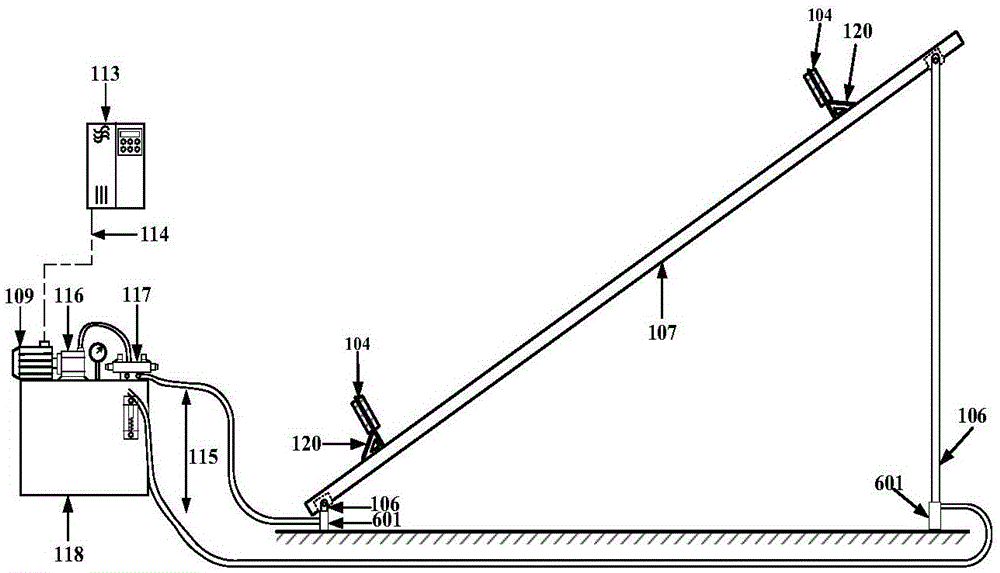

[0042] The pitching motion subsystem such as figure 1 and figure 2 Shown: including servo driver 113, servo motor 109, hydraulic pump 116, hydraulic valve group 117, hydraulic oil tank 118, pitching platform 107, hydraulic oil pipe 115, 2 anti-channeling rotating bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com