A high-precision station conversion device

A station conversion, high-precision technology, applied in metal processing, manufacturing tools, transportation and packaging, etc., can solve the problems of low precision, high market pricing, and emergency braking of the system, and achieve simple structure, low manufacturing cost, Precise effect of station conversion equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

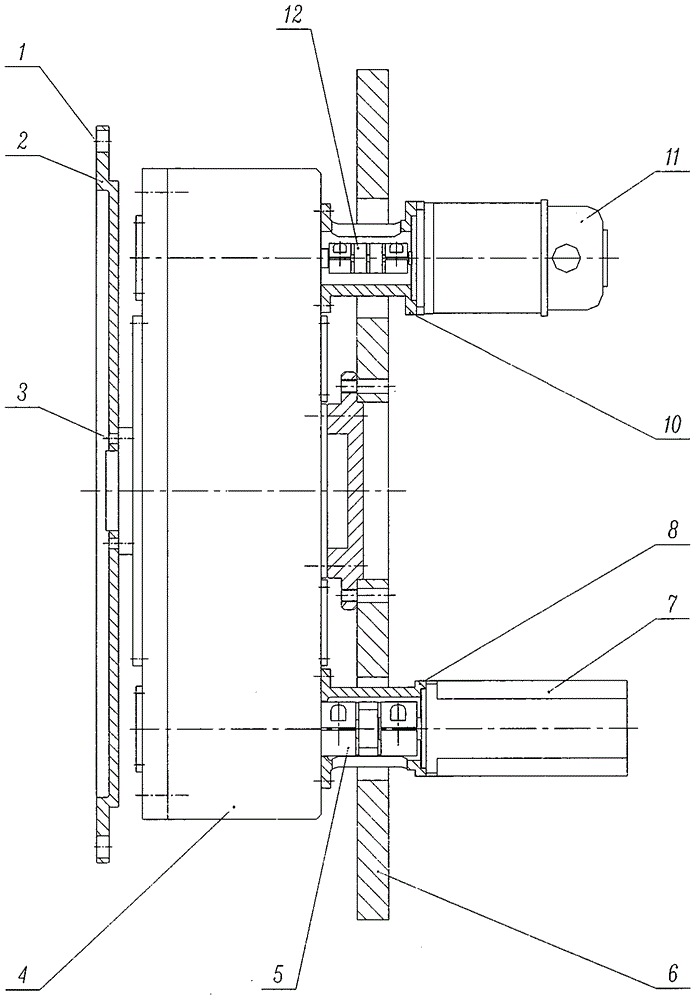

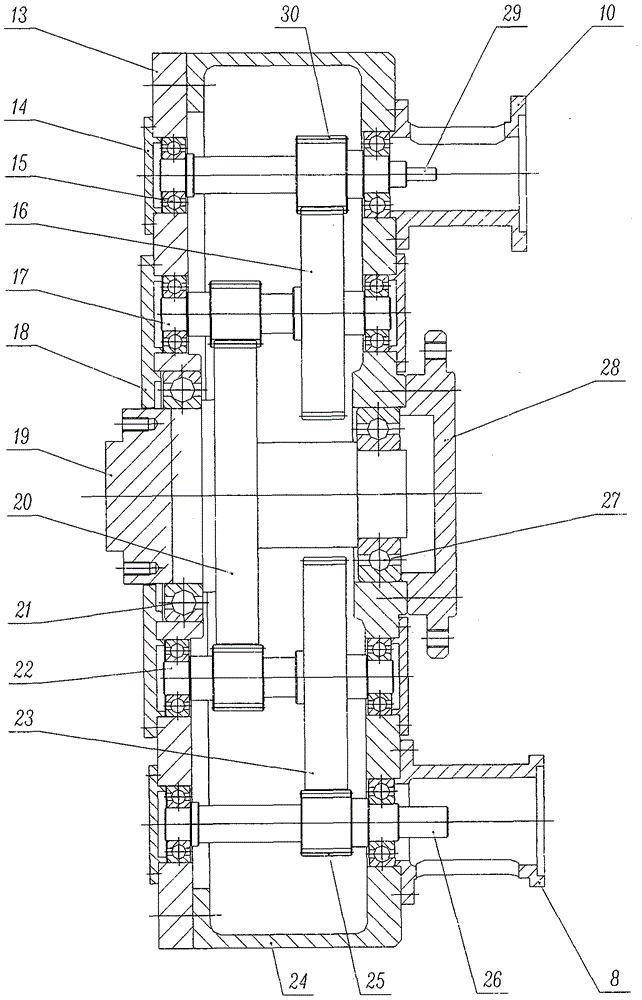

[0030] see Figure 1-2 As shown, the present invention relates to a high-precision station conversion device, including a work surface 6, on which a reduction box 4, a servo motor 7 and a constant torque motor 11 are arranged, and the distance between the work surface 6 and the work surface The central axis is provided with a servo motor support 8 and a constant torque motor support 10 in parallel at a certain distance, the servo motor 7 is located on the servo motor support 8, and the constant torque motor 11 is located on the constant torque motor support 10 Above; the reduction box 4 includes a reduction box body, an output end 35, a first input end 33 and a second input end 34, the reduction box body includes a reduction box seat 28, and a reduction box body 24 located on the reduction box seat 28 , rolling bearing 15, bearing cover 14 and reduction box cover 13; Output end 35 comprises output shaft 19 and the output gear 20 that is consolidated on output shaft 19, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com