Clamp loading and unloading device for large diameter deep sea simulator

A loading and unloading device, large-diameter technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low movement accuracy of the crane, inability to fine-tune the position of the clamp, and large movement range, and achieve easy automatic control and installation. The dismantling process is stable and the effect of reducing the lateral force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

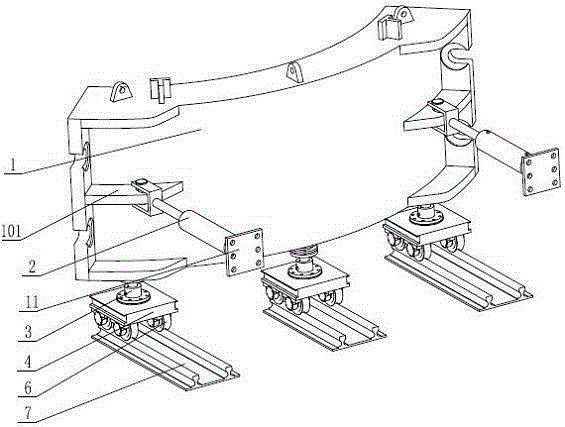

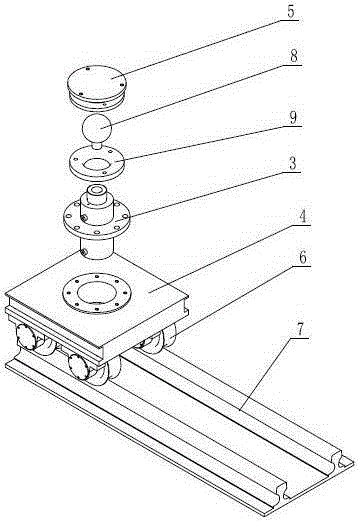

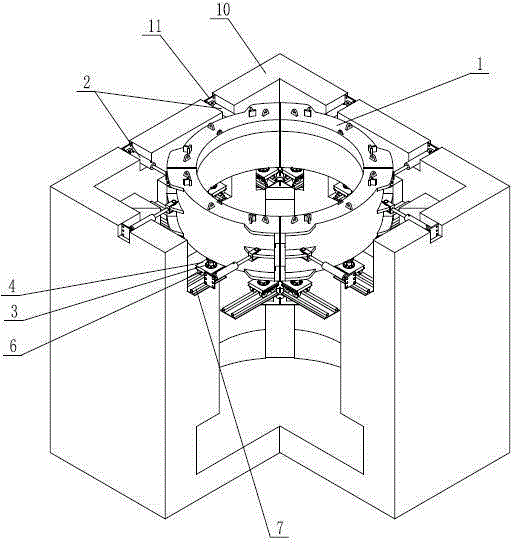

[0021] See figure 1 , figure 2 , image 3 , the present invention includes a circular clamp, which is installed on the outer peripheral surface of the pressure cylinder (not shown in the figure), and the circular clamp consists of four quarter-circumferential clamps Each clamp section 1 is equipped with a translation cylinder 2, the piston rod of the translation cylinder 2 is hinged with the pull ear 101 on the outer peripheral surface of the clamp section 1, and is used to drive the four clamp sections 1 to close Or open, the cylinder body of the translation cylinder 2 is fixed on the foundation 10 through the foundation reaction force frame 11; at least three vertical fine-tuning cylinders 3 are provided below each clamp section 1, and the two sides of the center of gravity of the clamp section 1 At least one fine-tuning oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com