Application and adsorption method of tea water extract or shaddock peel water extract for adsorbing heavy metal ions

A technology for adsorbing heavy metals and heavy metal ions, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low adsorption performance, limited adsorption capacity, secondary pollution, etc., and achieve superior adsorption High performance, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~36

[0038] 1. Preparation of tea water extract: crush 10g of tea into powder and add to 300ml of deionized water, extract in 70°C water bath for 3 times, each time for 1.5 hours, after each extraction, centrifuge the extract to obtain supernatant, combine each time The supernatant obtained after extraction was concentrated and freeze-dried to obtain powdered tea water extract. The freeze-drying time was 16 hours, and the cold trap temperature was -40°C;

[0039]Preparation of water extract of pomelo peel: crush 20g of tea leaves into powder and add to 300ml of deionized water, extract 3 times in a water bath at 80°C for 2.5 hours each time, centrifuge the extract after each extraction to obtain supernatant, combine each extraction The obtained supernatant was concentrated and freeze-dried to obtain a powdered aqueous tea extract. The freeze-drying time was 16 hours, and the cold trap temperature was -40°C;

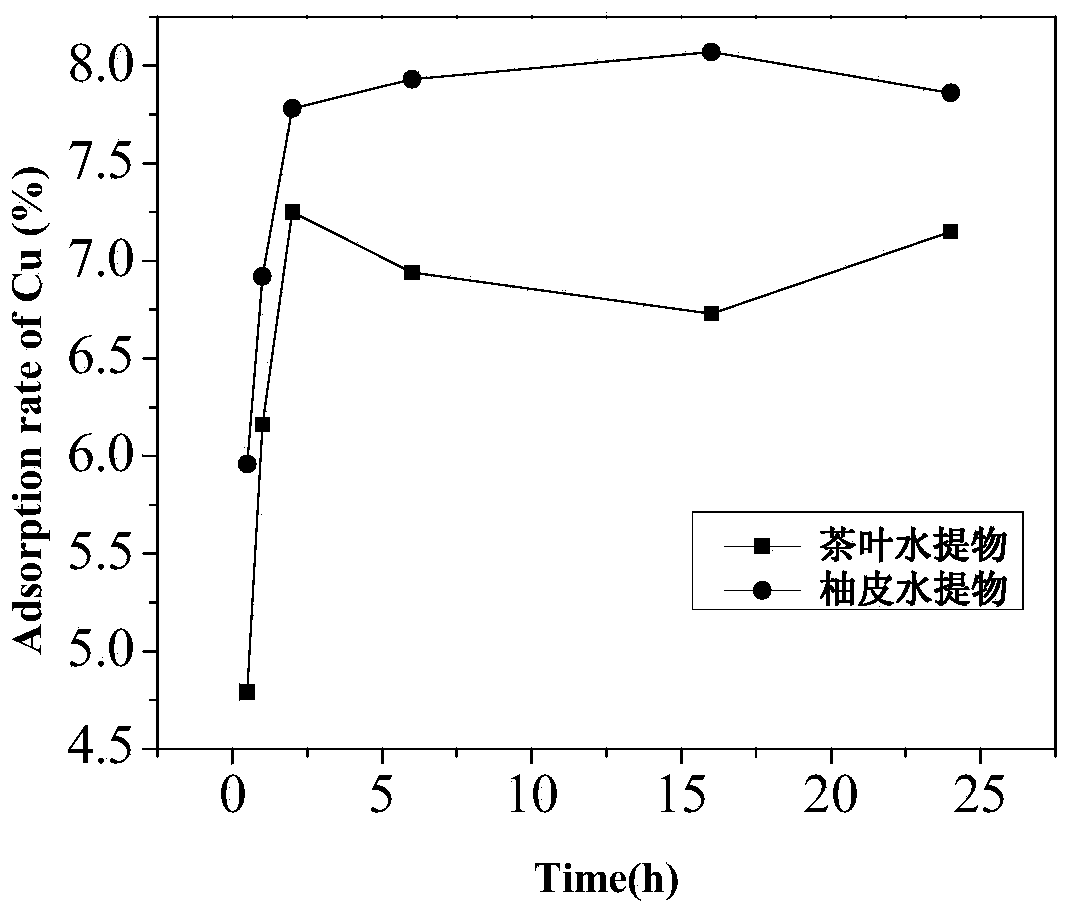

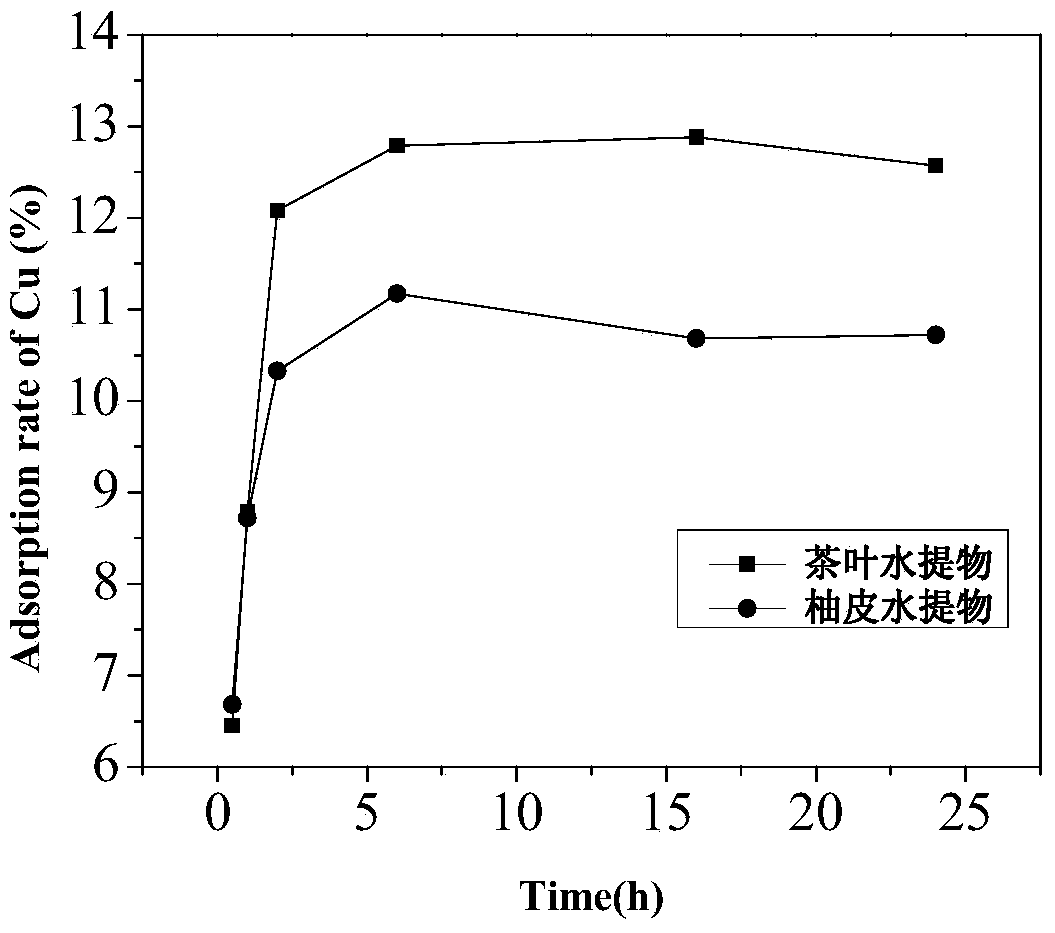

[0040] 2. The concentration of each configuration is 100mg·L -1 Tea wate...

Embodiment 37-54

[0051] 1. Preparation of tea water extract: crush 10g of tea into powder and add to 300ml of deionized water, extract twice in a water bath at 70°C for 2.5 hours each time, centrifuge the extract after each extraction to obtain supernatant, combine each time The supernatant obtained after extraction was concentrated and freeze-dried to obtain powdered tea water extract. The freeze-drying time was 16 hours, and the cold trap temperature was -40°C;

[0052] Preparation of pomelo peel water extract: crush 20g of tea leaves into powder and add to 300ml of deionized water, extract twice in a water bath at 80°C for 3.5 hours each time, centrifuge the extract after each extraction to obtain supernatant, combine each extraction The obtained supernatant was concentrated and freeze-dried to obtain a powdered aqueous tea extract. The freeze-drying time was 16 hours, and the cold trap temperature was -40°C;

[0053] 2. The concentration of each configuration is 100mg·L -1 Tea water extra...

Embodiment 55-90

[0058] This embodiment prepares the water extract of tea leaves and the water extract of pomelo peel in the same manner as in Example 37-54;

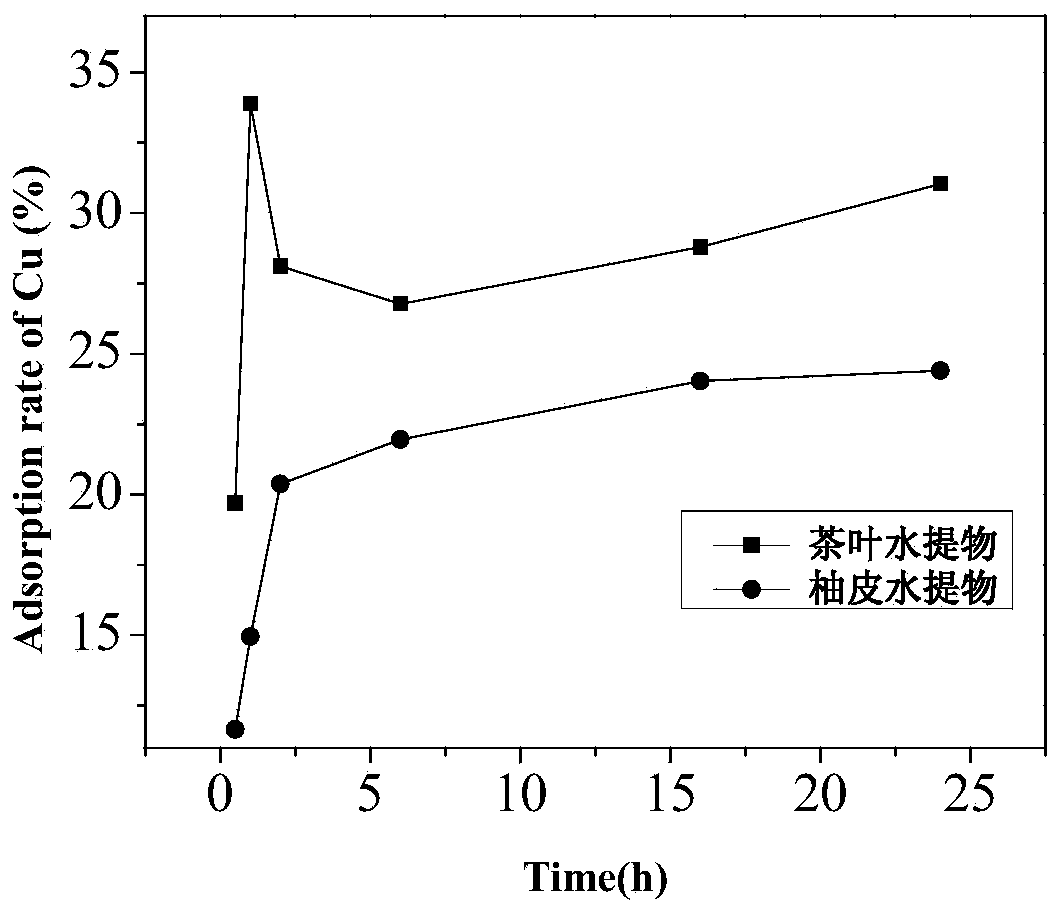

[0059] The concentration of tea and pomelo peel water extract solution is 100mg·L -1 , Cu 2+ The pH of the solution is 5, and the concentration is 10mg L -1 , take 10mL of water extract solution into a dialysis bag, clamp both ends with dialysis clips, put 50ml of Cu 2+ In the solution (the molar mass ratio is 7.8125mol / kg), oscillate on a reciprocating shaker (220r / min) at a constant temperature (25°C), and the sampling and measurement times are 10, 30, 60, 100, 120, 240, 360, 720 , 1440min, repeated three times. The results showed that in this case, the adsorption capacity of tea water extract to copper ions was 107.50mg / g, 156.55mg / g, 145.95mg / g, 139.65mg / g, 151.50mg / g, 153.22mg / g respectively. The adsorption capacity of the water extract of pomelo peel to copper ions is 68.85mg / g, 91.80mg / g, 112.35mg / g, 119.50mg / g, 116.34mg / g, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com