Inverted T-shaped prestressed double-section support pile

A prestressed and prestressed steel strand technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of long manufacturing period, limited pile distance, high cost, improve shear performance and reduce the amount of steel bars , the effect of accurate joint size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

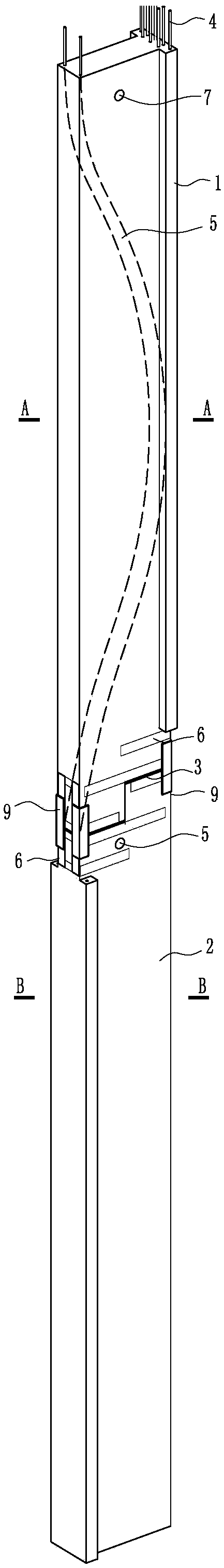

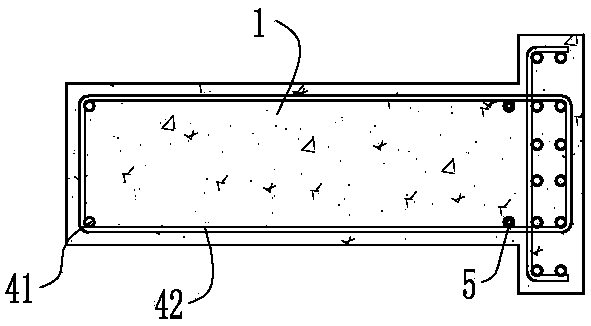

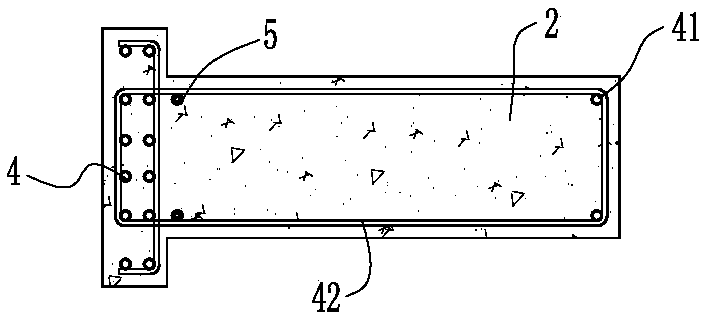

[0027] see Figure 1 to Figure 6 , a kind of rectangular prestressed double-joint support pile provided in the present invention comprises an upper section pile 1 and a lower section pile 2, the lower end of the upper section pile 1 is provided with a gap 3, and the upper end of the lower section pile 1 is also provided with a gap 3. The upper section of pile 1 and the lower section of pile 2 are inverted T-shaped sections, the flange protrudes 75-150mm, and the main reinforcement is prestressed steel strand 4 buried on the side with the flange, which can increase the tension of prestressed steel strand 4. Tensile stress can be increased to increase the prestressing degree of the supporting pile, so that the pile body can work without cracks, thereby greatly improving the stiffness of the pile and reducing deformation. The pile body is longitudinally embedded with prestressed steel strand 4 as the main reinforcement to reduce the amount of reinforcement in the pile. The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com