Method for designing tunnel composite lining structure with load acting on stratum boundaries

A technology for structural design and stratum boundaries, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems that the load-structure method cannot be well adapted, waste of building materials such as steel bars, and poor social and economic benefits, etc., and achieve accurate calculation results Reliable, saving steel consumption, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] refer to Figure 1 to Figure 4 , a kind of load of the present invention acts on the tunnel composite lining structure design method of stratum boundary, carry out as follows:

[0016] (1) Determine the basic parameters required for the design;

[0017] (2) Calculate the tunnel load;

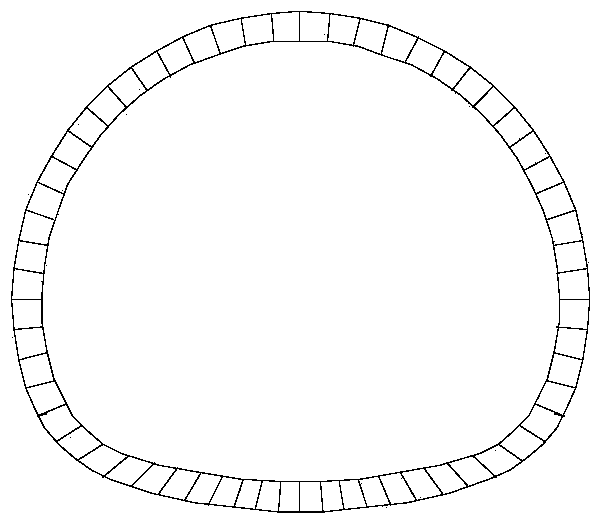

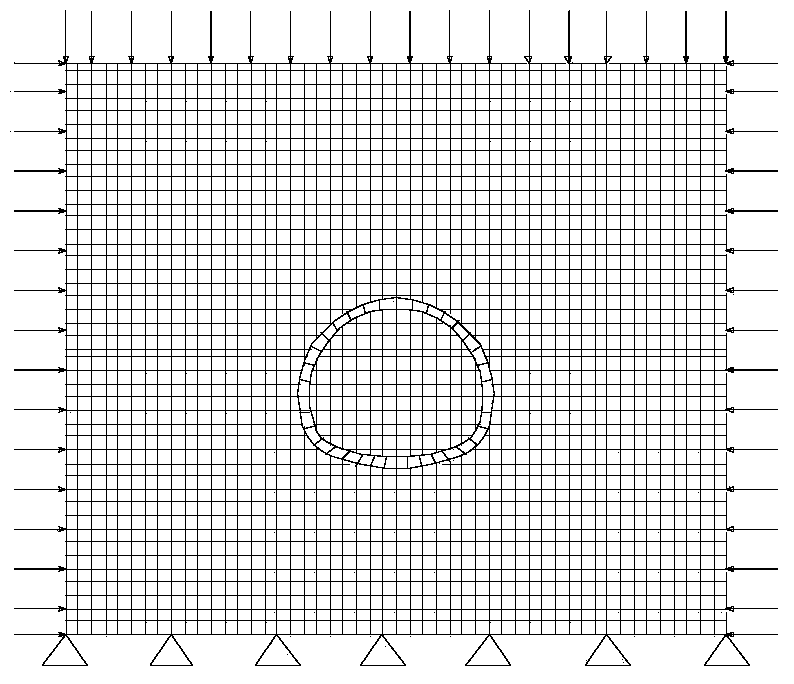

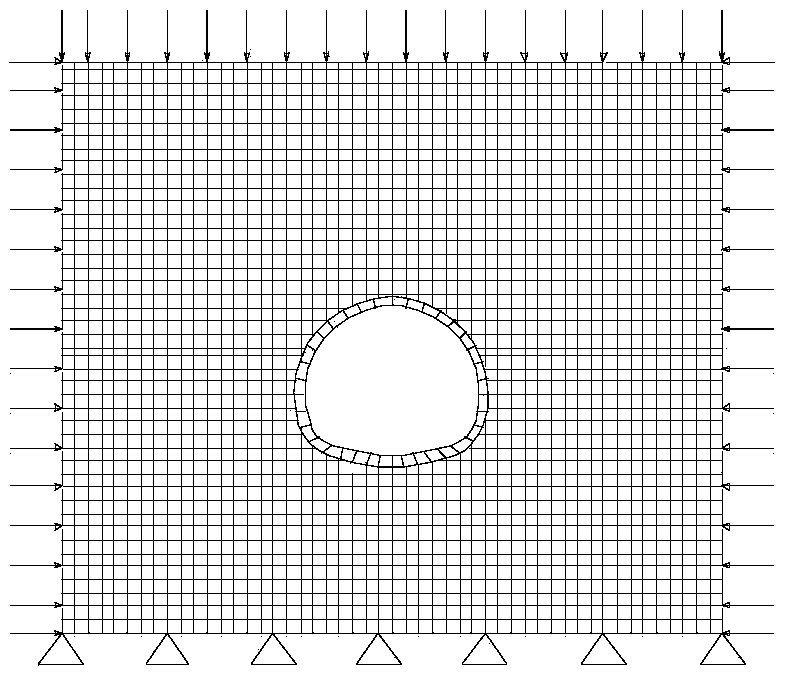

[0018] (3) Establish the design method model, use two-dimensional solid structural elements to simulate the surrounding rock, use the plane strain model as the design model, adopt the elastic-plastic constitutive relation, use the beam element to simulate the primary support of the composite lining and the secondary lining, and use the waterproof layer The link unit is simulated, and the unit is only subjected to pressure;

[0019] (4) Carry out grid division, primary support and secondary lining are divided by mapped grid;

[0020] (5) Constrain the lower boun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com