Method for measuring optical axis in aspheric surface detection by means of self-aligning plane mirror

A technology for measuring light and plane mirror, applied in the field of optical detection, can solve the problem of low measurement accuracy, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

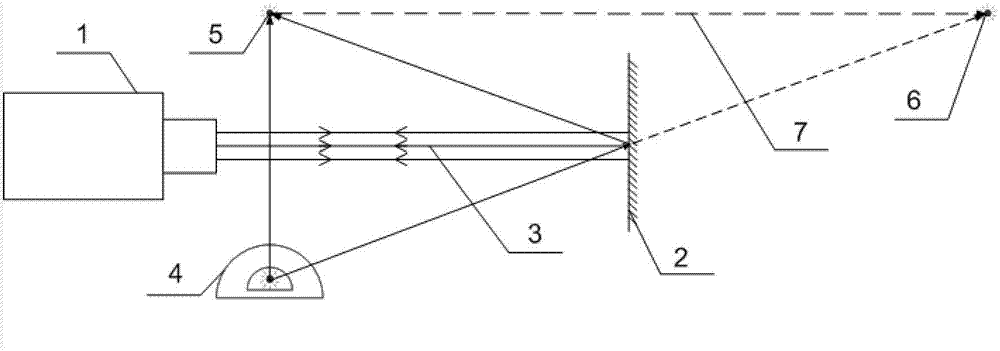

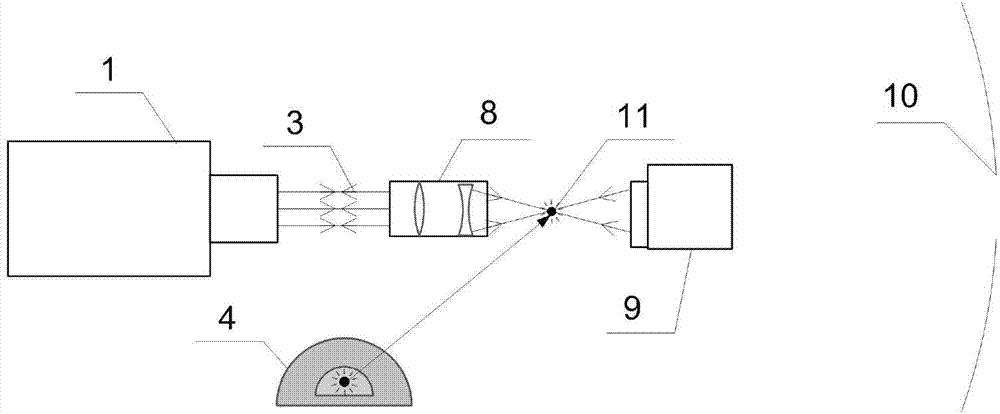

[0025] a. Place the plane mirror 2 close to the detected aspheric surface 10 (the farther away from the interferometer 1, the higher the measurement accuracy), and let the parallel light 3 emitted by the interferometer 1 shine on the plane mirror 2 Within the effective aperture; adjust the two angular directions of the yaw and pitch of the plane mirror 2, so that the interference fringes formed in the interferometer 1 are in the state of zero fringes; use the interferometer 1 to measure and analyze, and check the surface shape detection results Tilt amount (tilt item after zernike fitting), and continue to adjust the plane mirror 2 until the tilt is close to 0, and the adjustment is completed to realize the self-alignment of the plane mirror 2 to the interferometer;

[0026] b. Use the target ball of the laser tracker 4 to guide the laser light of the laser tracker 4 to the self-collimating plane mirror 2 and form a reflection, use the target ball to obtain the reflected laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com