Mounting module composed of LTCC component and structure cavity

A technology for installing modules and components, which is applied in the direction of radio wave measurement systems, instruments, etc., can solve the problems of easy damage and inconvenient disassembly of LTCC modules, and achieve the effect of easy maintenance and replacement, convenient disassembly, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

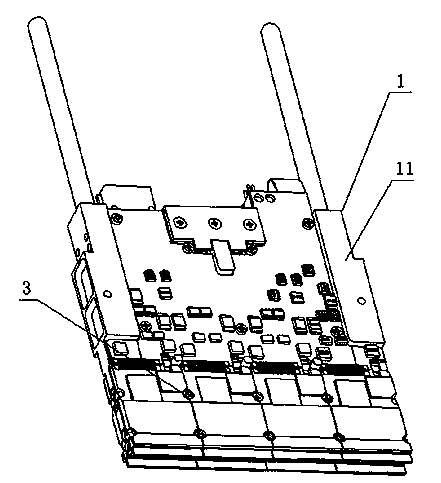

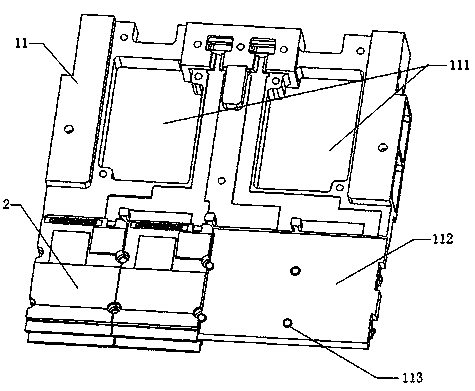

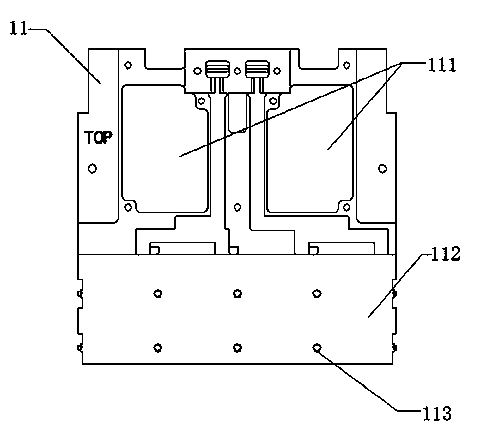

[0021] as attached figure 1 , 2 As shown, the installation module composed of LTCC components and structural cavity in this embodiment includes structural cavity 1 and LTCC component 2, as attached image 3 As shown, the structural cavity 1 is composed of symmetrical structural plates 11 on the front and back sides, and the surfaces of the structural plates 11 on both sides are provided with weight-reducing grooves 111. The interior of the structural cavity 1 is a hollow cavity for accommodating electronic components. The lower part of the surface of the front and back structural plates 11 has an installation groove 112 for installing LTCC components, and the area of the installation groove 112 is provided with a threaded hole 113, and the orifice of the threaded hole 113 is raised; as attached Figure 4 As shown, the LTCC assembly 2 includes an LTCC template 21 and a tungsten copper plate 22 welded on the back of the LTCC template 21. The left and right edges of the LTCC a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com