Selection optimization method of numerically-controlled machine tool thermal error compensation modeling temperature measuring point combination

A technology of CNC machine tool and optimization method, which is applied in the direction of simulator, program control, computer control, etc., to achieve the effect of saving temperature sensors and high modeling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and implementation process, the present invention will be further described:

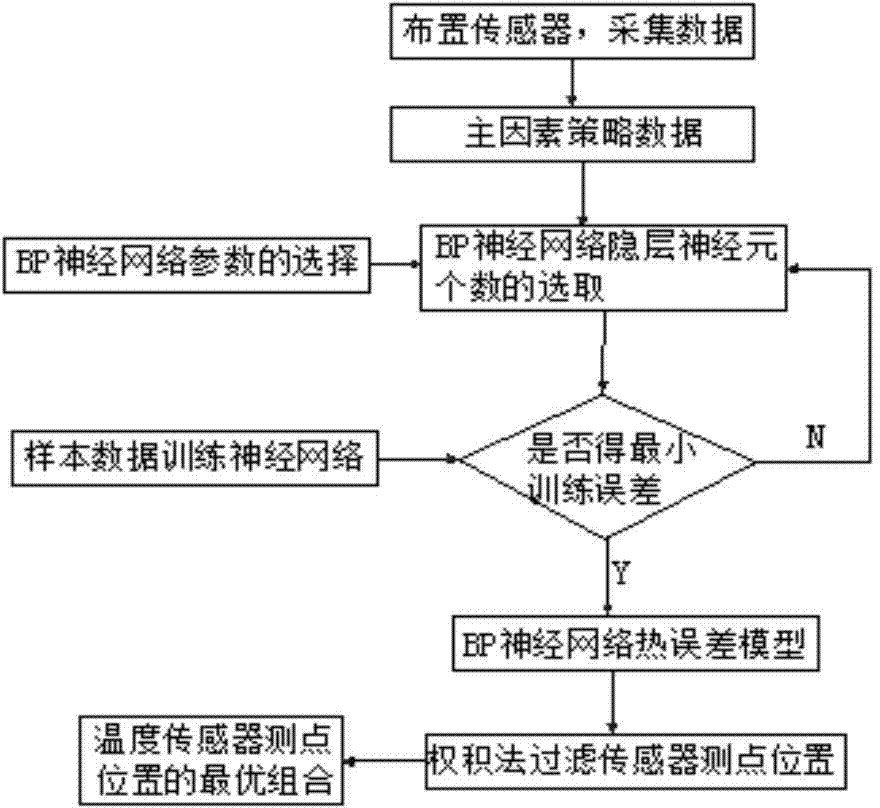

[0030] The method for selecting and optimizing the thermal error compensation modeling temperature measurement point of the machine tool described in the present invention is a method for selecting the weight product value based on the principal factor strategy and the BP neural network, and is realized according to the following steps:

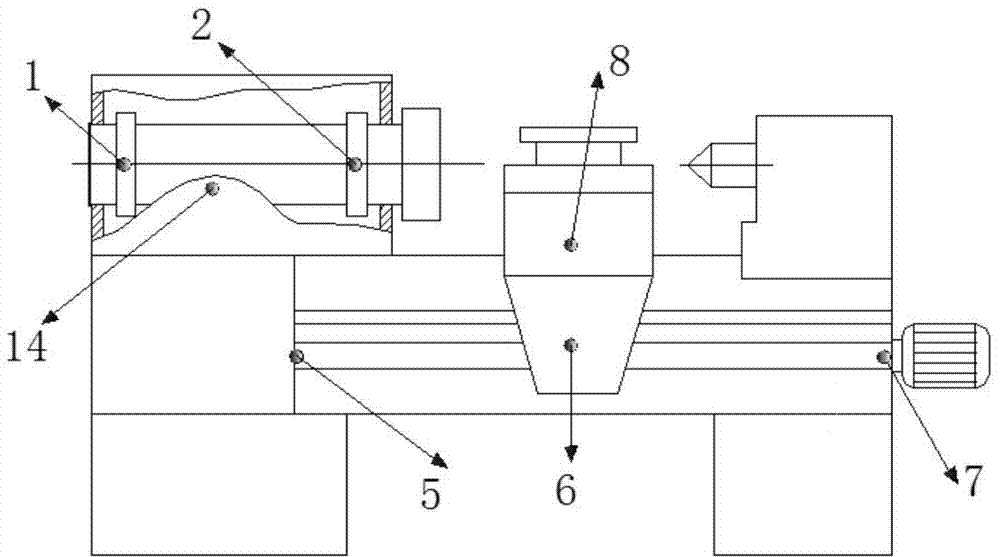

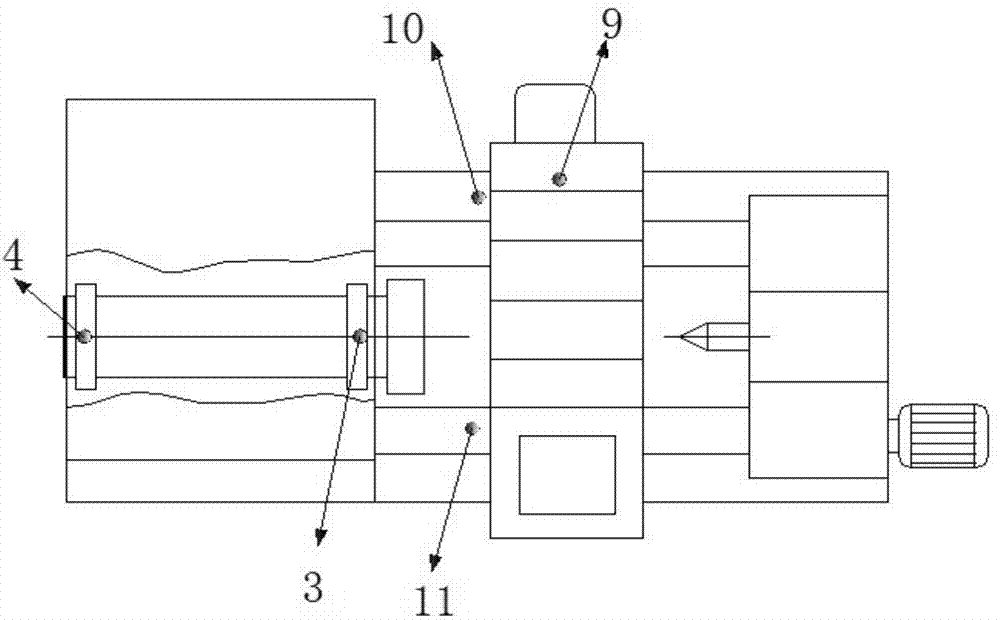

[0031] First, consider the relevant factors that generate thermal errors, including the heat generated by the reciprocating motion of the moving parts of the machine tool, the heat generated by the motor, the heat transfer of the coolant and hydraulic oil, and the influence of the ambient temperature, etc., and analyze and determine the sensor layout in the experiment of collecting machine tool temperature data. location, such as figure 2 , 3 , 4, 16 sensor layout positions: sensors numbered 1 and 4 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com