An extended combined module power socket and its application

A technology for expanding modules and module power supplies, which is applied in the direction of circuits, electrical components, coupling devices, etc., and can solve the problems of insufficient plug space, inability to insert modules, free movement and combination, etc., to avoid inability to insert, reduce quantity, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

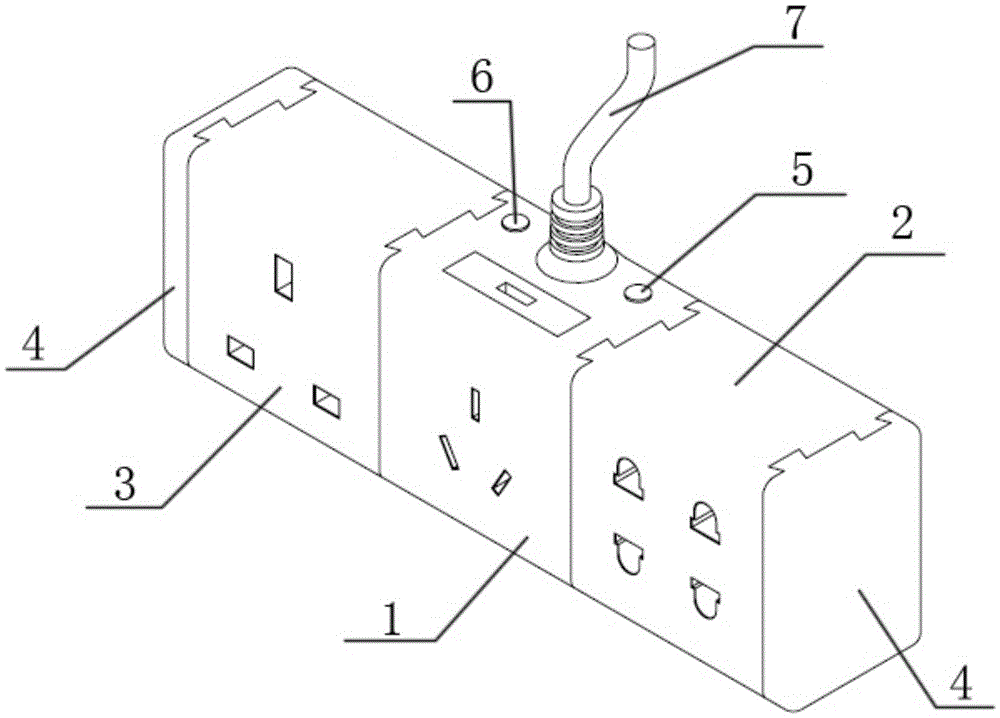

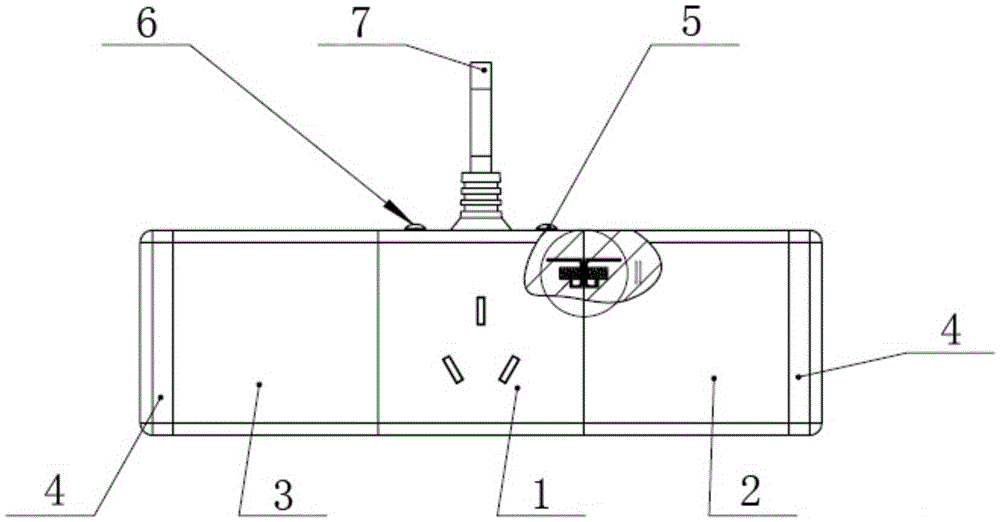

[0034] like figure 1 As shown, the housing of the main module in the present invention is made of plastic or bakelite or metal, and the housing is provided with power wiring, power indicator light, fuse, main switch, rated power, etc., and the three metal plugs of the three-hole socket The connection part is correspondingly connected to the plug points in the three jacks on the left and right side walls of the main module through wires.

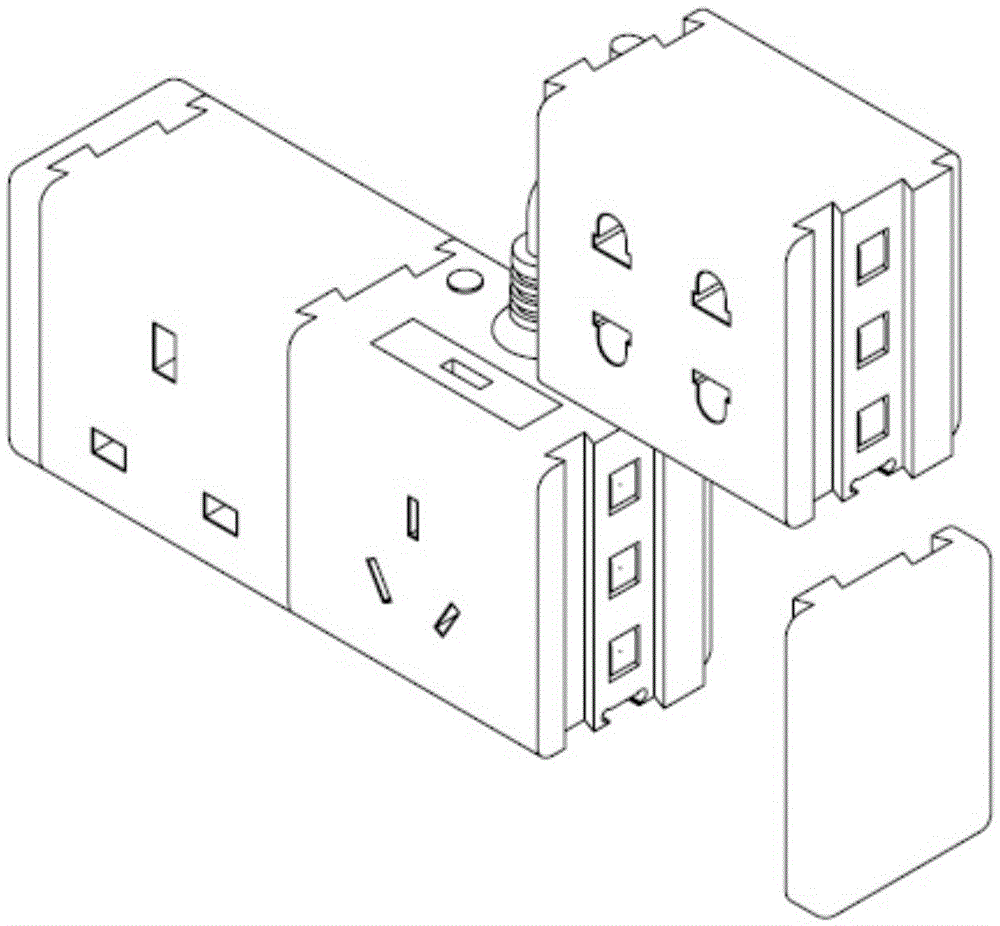

[0035] Expansion module: the shell is made of plastic or bakelite or metal materials. Different countries have different power socket standards. The shell is equipped with multi-shaped sockets and sockets with the same shape on both sides. A module has jacks on the front and back sides. Similarly, the metal socket part of the jack is correspondingly connected to the plug points in the three jacks on the left and right side walls of the expansion module through wires.

[0036] Insulation cover ( Figure 8 ) two pieces are identical in shape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com