Non-power slide recreation facility

A technology of amusement facilities and slideways, which is applied in the field of amusement facilities and non-powered slideway amusement facilities, can solve the problems of increasing operating costs, shortening service life, reducing reliability, etc., and achieves good effects of absorbing impact energy, improving work efficiency, Effect of reducing installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

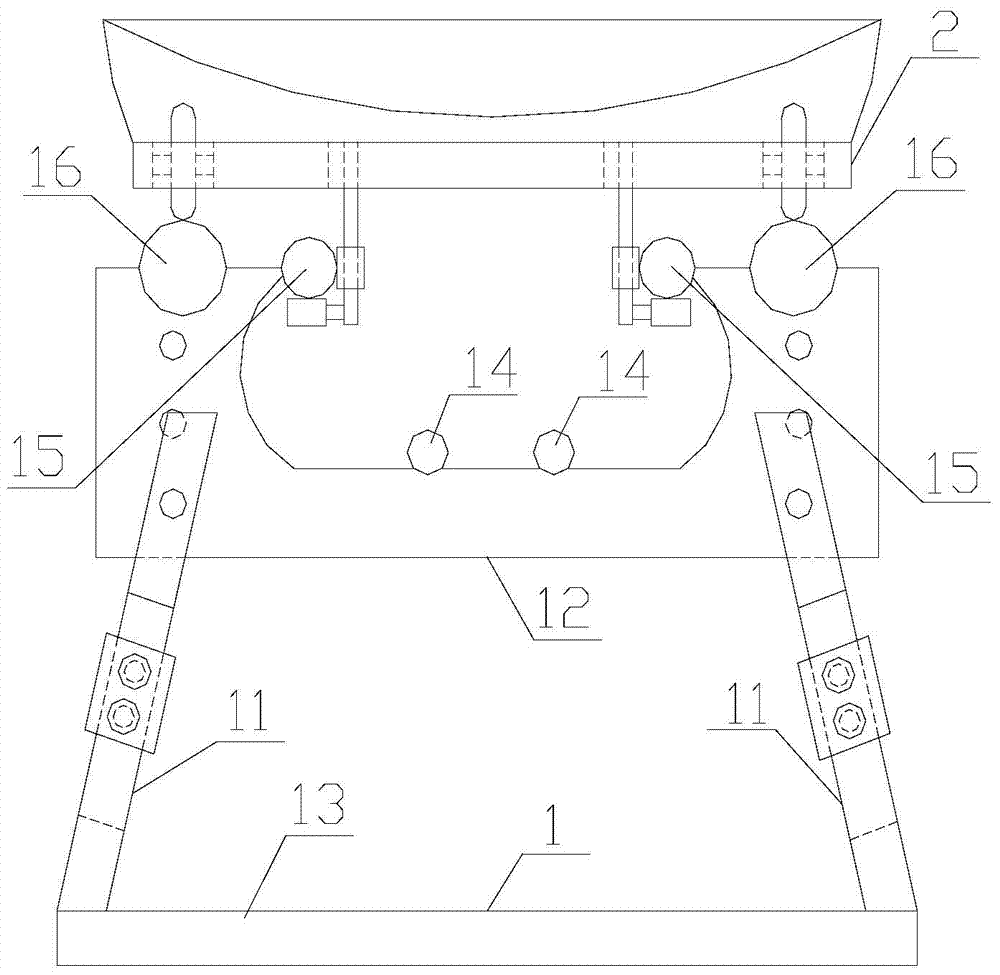

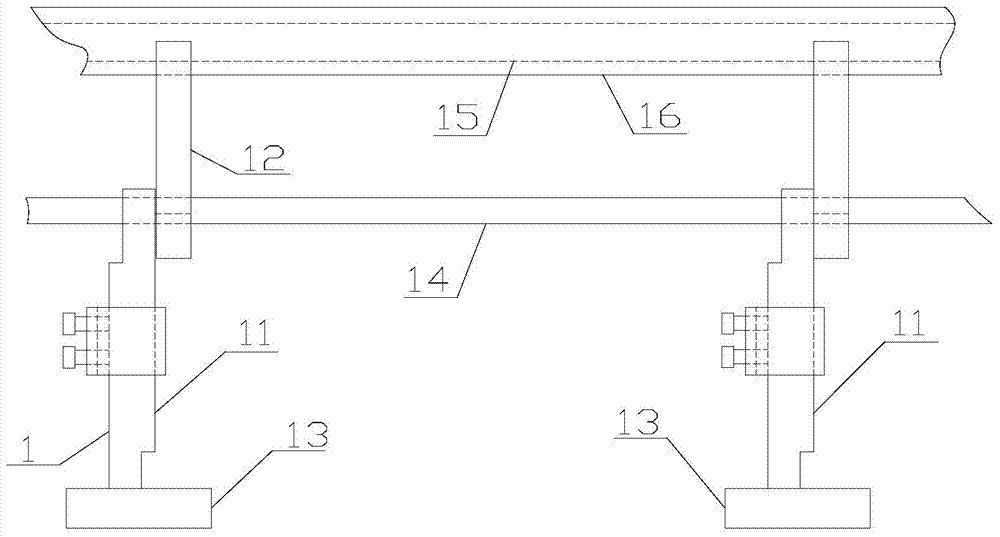

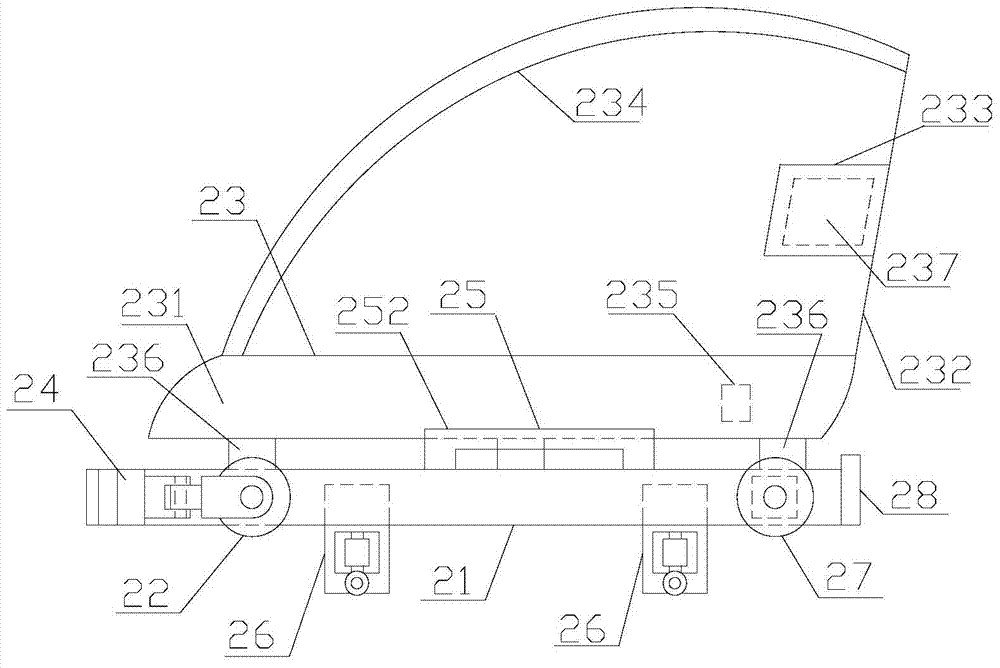

[0028] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6, a non-powered slideway amusement facility of the present invention, comprising a descending slideway 1 and a trolley 2 matched with the descending slideway 1, the said descending slideway 1 includes several supporting columns 11, several mounting beams 12, several bases 13, a A pipe rail 14, a second pipe rail 15 and a third pipe rail 16, the base 13 is provided with a support column 11, the support column 11 is equipped with a mounting beam 12, and the inner bottom surface of the mounting beam 12 is provided with The first pipe rail 14, the inner side of the installation beam 12 is provided with the second pipe rail 15, and the top of the installation beam 12 is provided with the third pipe rail 16, and the center point of the third pipe rail 16 is connected with the second pipe rail. The center point of the pipe rail 15 is on the same horizontal straight line. The support column 11 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com