Detecting system for crimping process of stamping parts

A technology for process detection and sheet metal parts, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that the detection device cannot perform large-scale continuous non-destructive testing, etc., to save manpower, have broad application prospects, and improve labor. The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is specifically described below by way of examples.

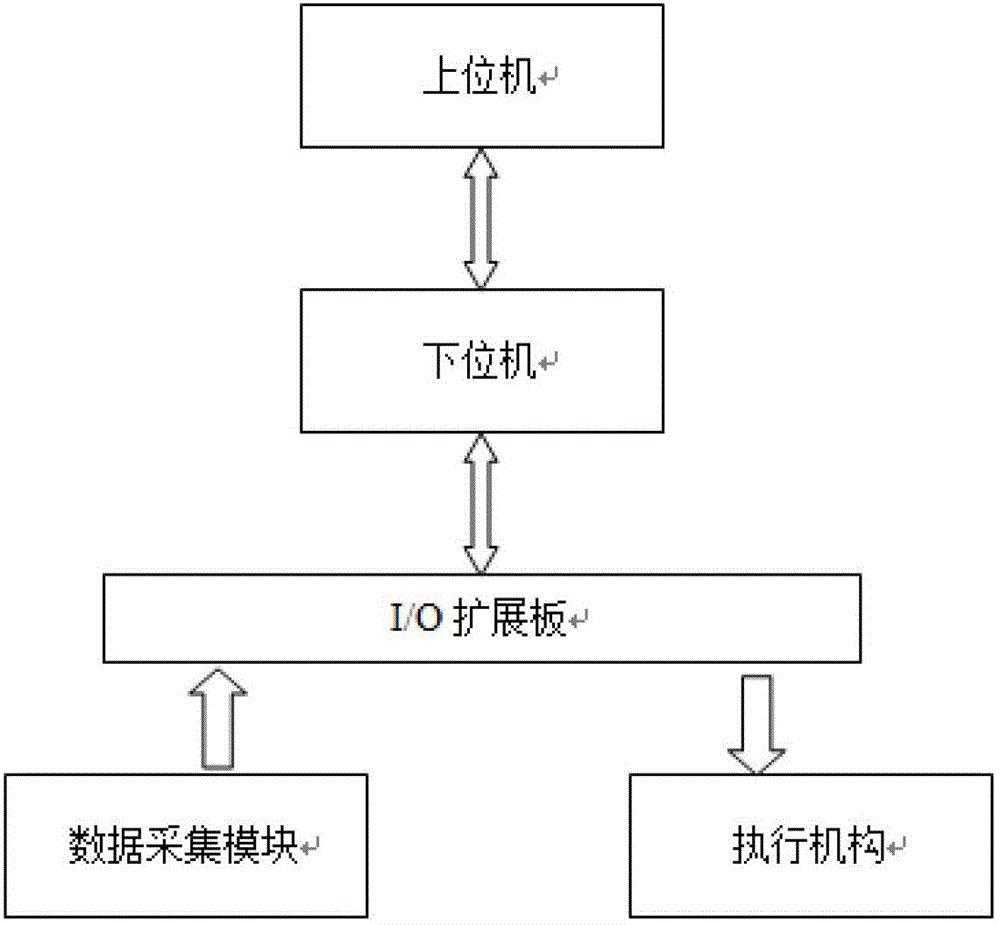

[0013] A detection system for the crimping process of sheet metal parts, including an upper computer, a lower computer, a data acquisition module, an actuator, etc., the upper computer and the lower computer are connected by communication, the upper computer is used for human-computer interaction, and the The lower computer is used to process data and store control logic, the lower computer is connected with the data acquisition module and the actuator, and the actuator is an actuator that controls the action of the stamping machine, and it is characterized in that the data acquisition module Contains sensors, switching signal sources, and I / O expansion boards that input these signals to the lower computer. A preferred solution is that the sensors include pressure and displacement sensors. The switch signal source includes a switch button for controlling the start and stop of the system, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com