Press machine

A press and body technology, applied in the field of presses, can solve the problems of damaged molds and low work efficiency, and achieve the effect of preventing damage to the lower mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

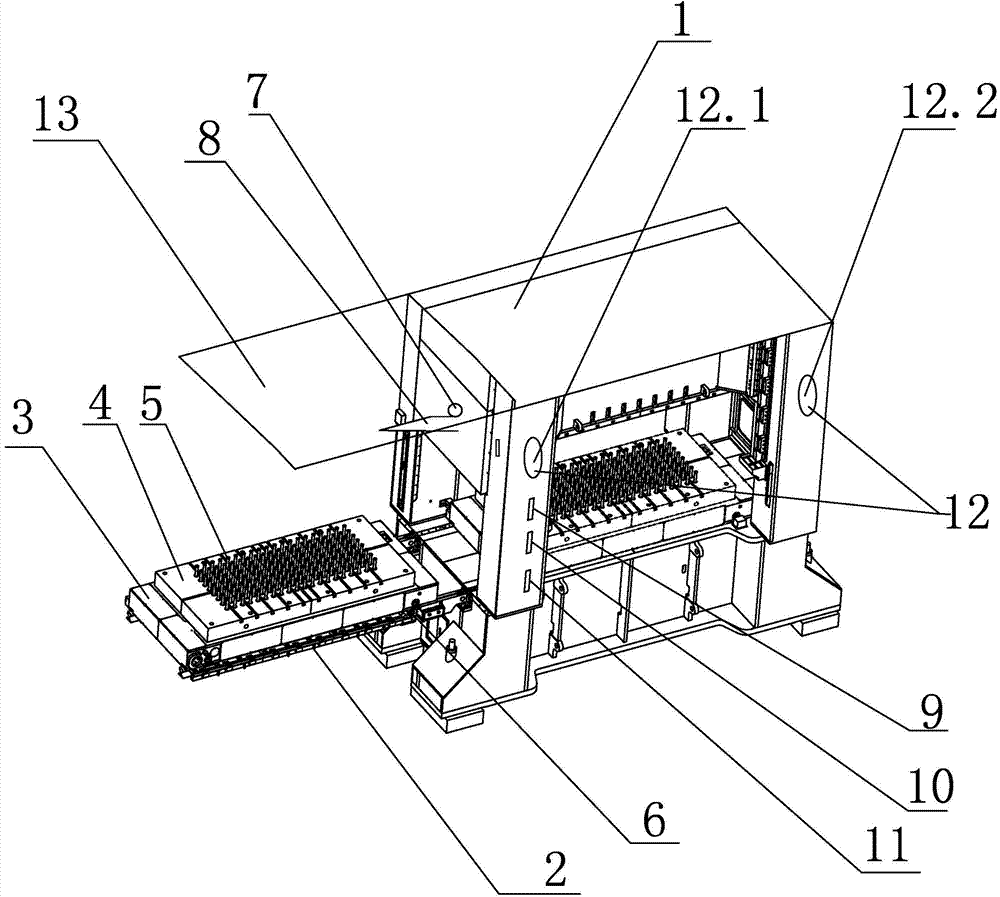

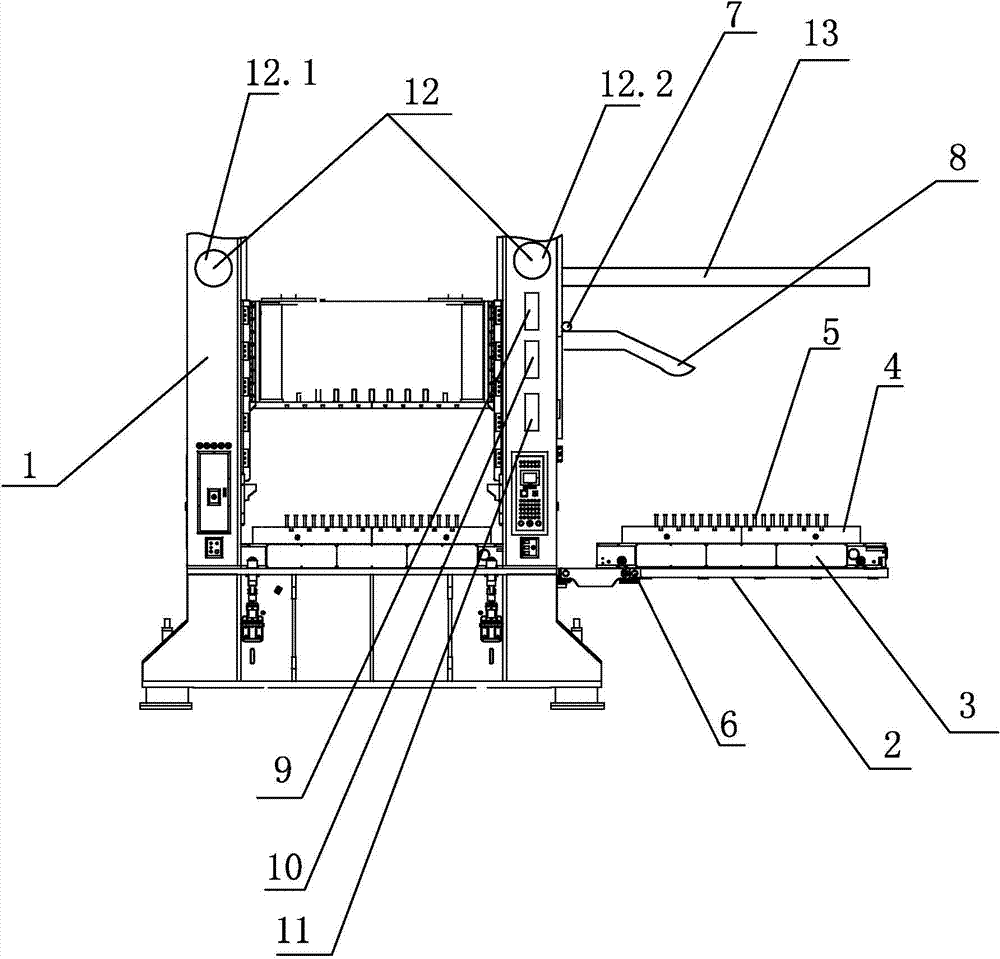

[0014] Attached below figure 1 The present invention is described in further detail.

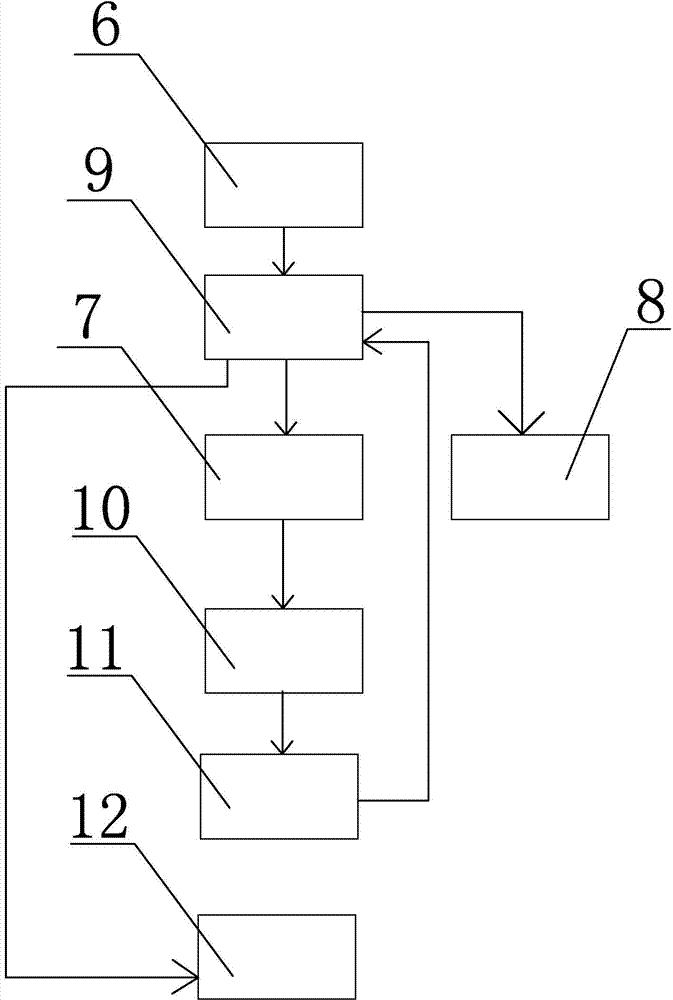

[0015] A kind of press machine of the present invention, its structure comprises press machine body 1, the guide rail 2 that is arranged on press machine body 1, the trolley 3 that is installed on guide rail 2, the table plate 4 that is installed on trolley 3, described The table plate 4 is provided with a plurality of slots, and the mold pad pins 5 are inserted into the slots, and it is characterized in that: the press machine is also provided with a position for detecting the mold pad pins 5 plugged into the table plate 4 The detection mechanism includes a sensor 6 for sensing the position of the trolley 3, a lighting device 7 for providing illumination, a camera 8 for photographing the position of the upper die pad pin 5 of the platform 4, and a camera 8 for processing The sensor 6 senses the signal and controls the controller 9, the data memory 10, the image processor 11 and the alarm 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap