Bamboo stick polishing machine

A polishing machine, bamboo stick technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve problems such as unfavorable production, high work intensity, affecting product quality, etc., to improve utilization and production. Efficiency, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

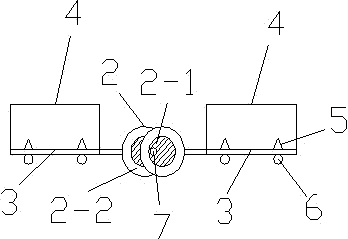

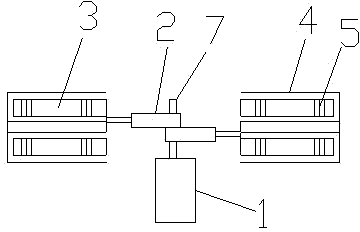

[0012] A bamboo stick grinding machine, comprising a shaft 7, an eccentric wheel 2 and a machine frame 4, two eccentric wheels 2 are installed on the shaft 7, and the two eccentric wheels are axisymmetric, and the eccentric wheel 2 is composed of an inner wheel 2 -1 and an outer wheel 2-2, the inner wheel 2-1 is fixed on the shaft 7, and the outer wheel 2-2 is connected to the machine frame 4 through a connecting rod.

[0013] A roller 6 is installed below the machine frame 4 , and a charging bottom plate 3 is installed on the roller 5 in the machine frame 4 , and the eccentric wheel 2 is connected with the motor 1 through a shaft 7 .

[0014] Angular baffles 5 are installed on the charging bottom plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com