Refrigerator handle injection molding method and refrigerator handle

A technology for handles and refrigerators, which is applied in the direction of wing leaf handles, wing leaf handles, coatings, etc. It can solve the problems of difficult cleaning of decorative parts, high cost of molds, and lack of scratch resistance, etc., to meet the needs of increasing tactility and texture, The manufacturing process is simple and easy to realize, and the effect of improving the overall aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

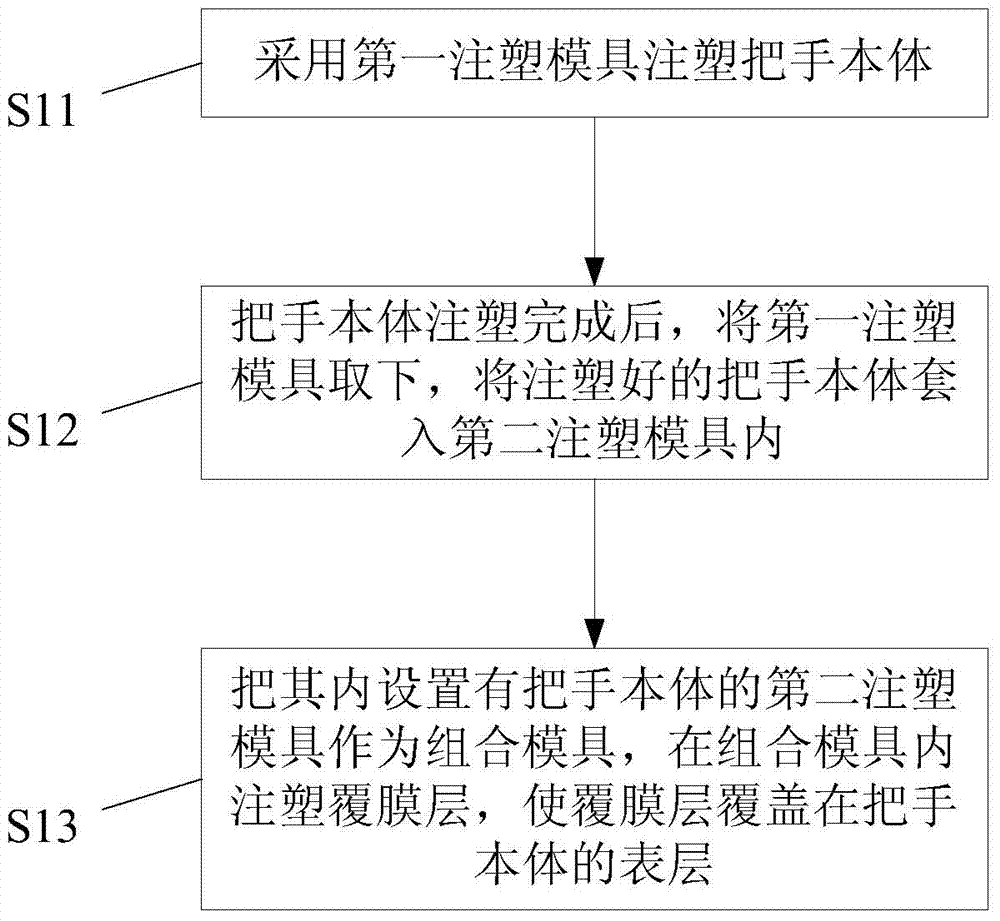

Embodiment 1

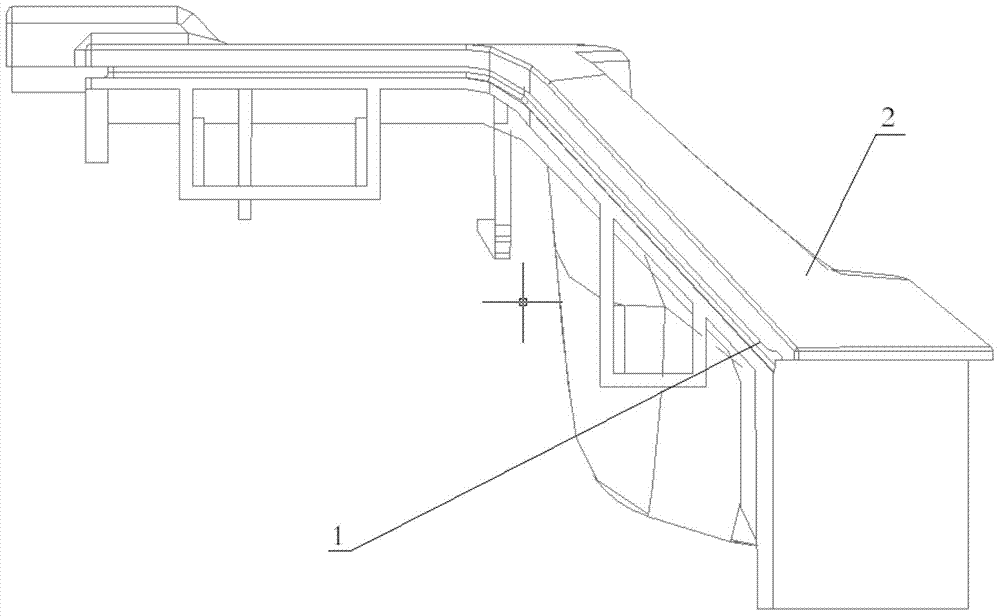

[0034] figure 1 It is a structural schematic diagram of the refrigerator handle provided by the present invention. Such as figure 1 As shown, the handle of the refrigerator includes a handle body 1 , wherein the surface of the handle body 1 is provided with a film layer 2 , and at least part of the surface layer of the handle body 1 is covered by the film layer 2 .

[0035] Since the surface layer of the handle body 1 included in the refrigerator handle is provided with a coating layer 2, at least part of the surface layer of the handle body 1 is covered by the coating layer 2, and the coating layer 2 is firmly covered on the handle body 1. The surface layer is durable and will not fall off, so the surface of the handle body 1 is not easy to fade or change color.

[0036] In this embodiment, as a preferred solution, the entire surface layer of the handle body 1 is covered by the film layer 2 .

[0037] In this embodiment, as a preferred solution, the coating layer 2 is tran...

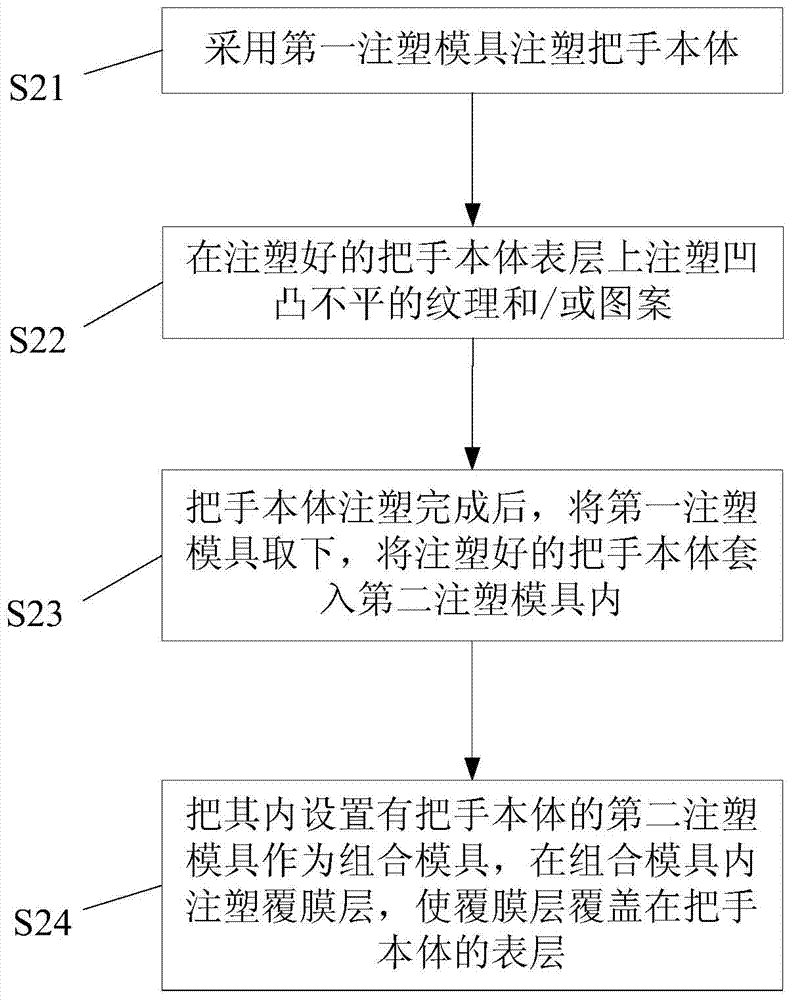

Embodiment 2

[0044] The difference between the solution provided in this embodiment and the solution provided in Embodiment 1 is that, in this solution, the upper surface of the handle body 1 or the inside of the coating layer 2 is provided with uneven textures and / or The pattern, or the upper surface of the handle body 1 and the interior of the coating layer 2 are both provided with uneven textures and / or patterns.

[0045] In this embodiment, as a preferred solution, the coating layer 2 is provided with a pattern inside. The pattern can be an uneven 3D three-dimensional pattern, or a planar pattern. This scheme can realize the diversified decorative effects of the handle of the refrigerator, and can display different appearances and colors, specifically by changing the internal patterns. Similarly, uneven textures can also be provided inside the coating layer 2 , or uneven textures and patterns can also be provided inside the coating layer 2 .

[0046] And when the pattern set in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com