Automobile torsion beam suspension frame

A technology of torsion beam and suspension, applied in the direction of suspension, vehicle components, interconnection system, etc., can solve the problems of poor continuity of torsion beam suspension, high cost, affecting ride comfort and controllability, etc., and reduce cracking. Effects of risk, stress reduction, ease of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

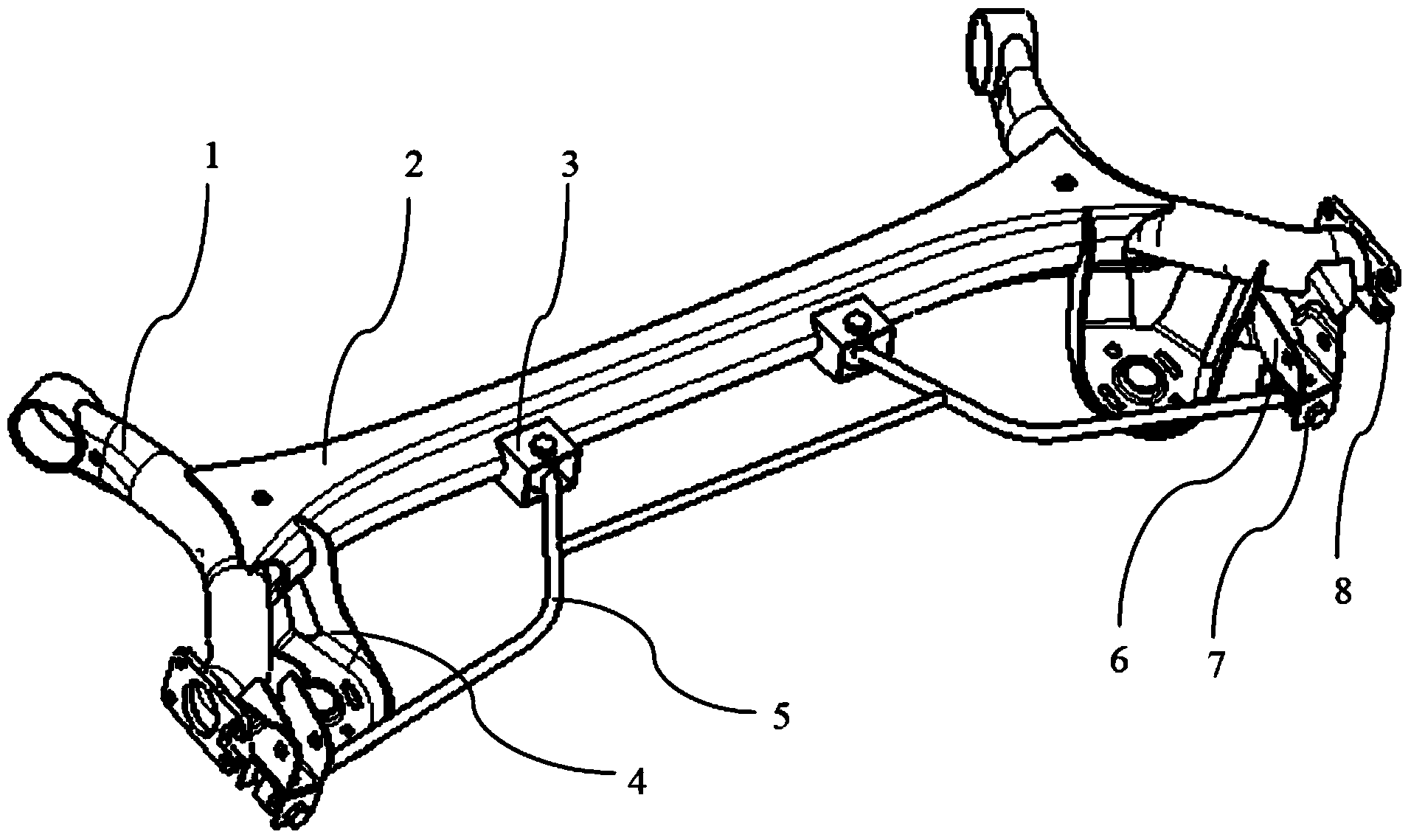

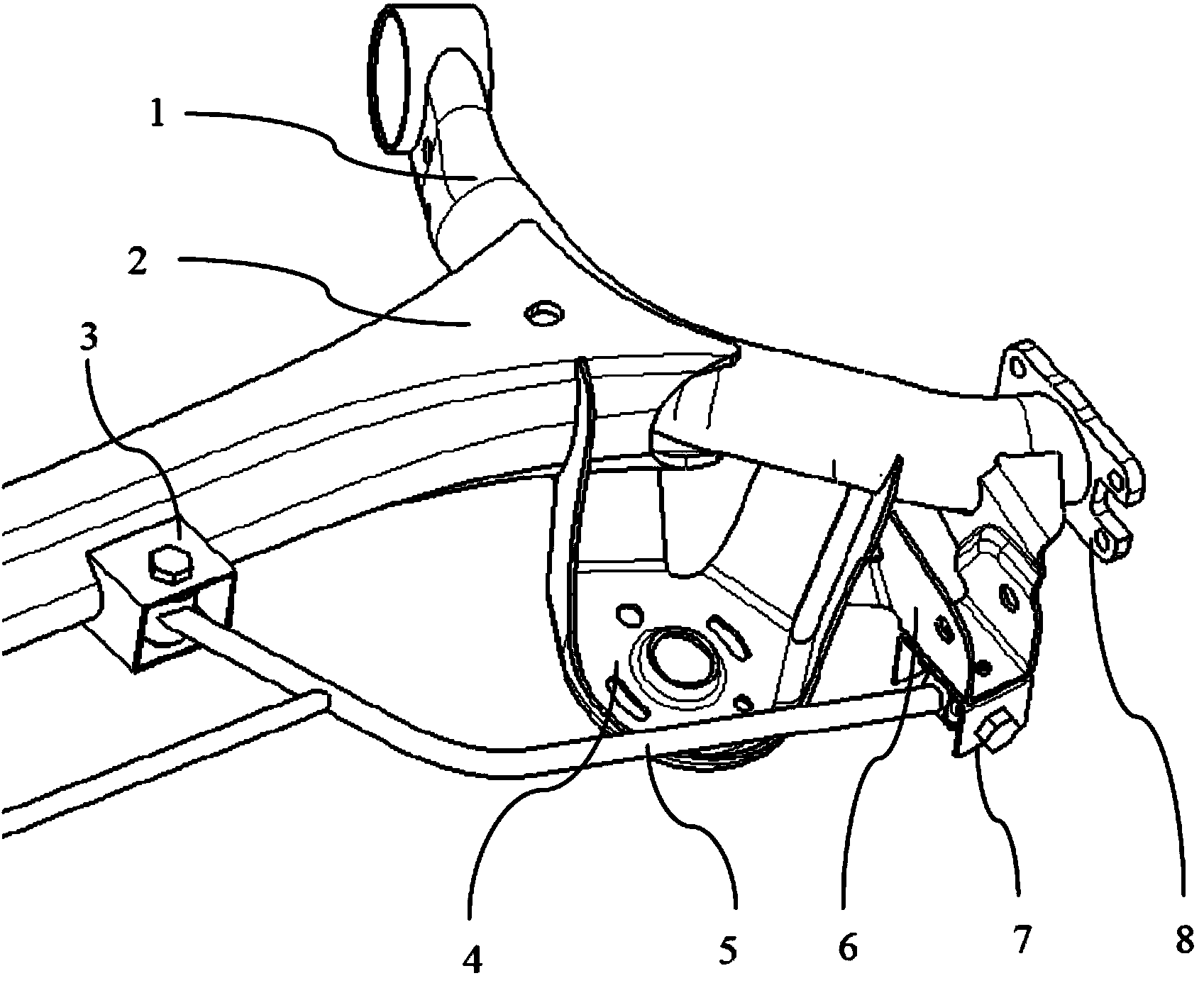

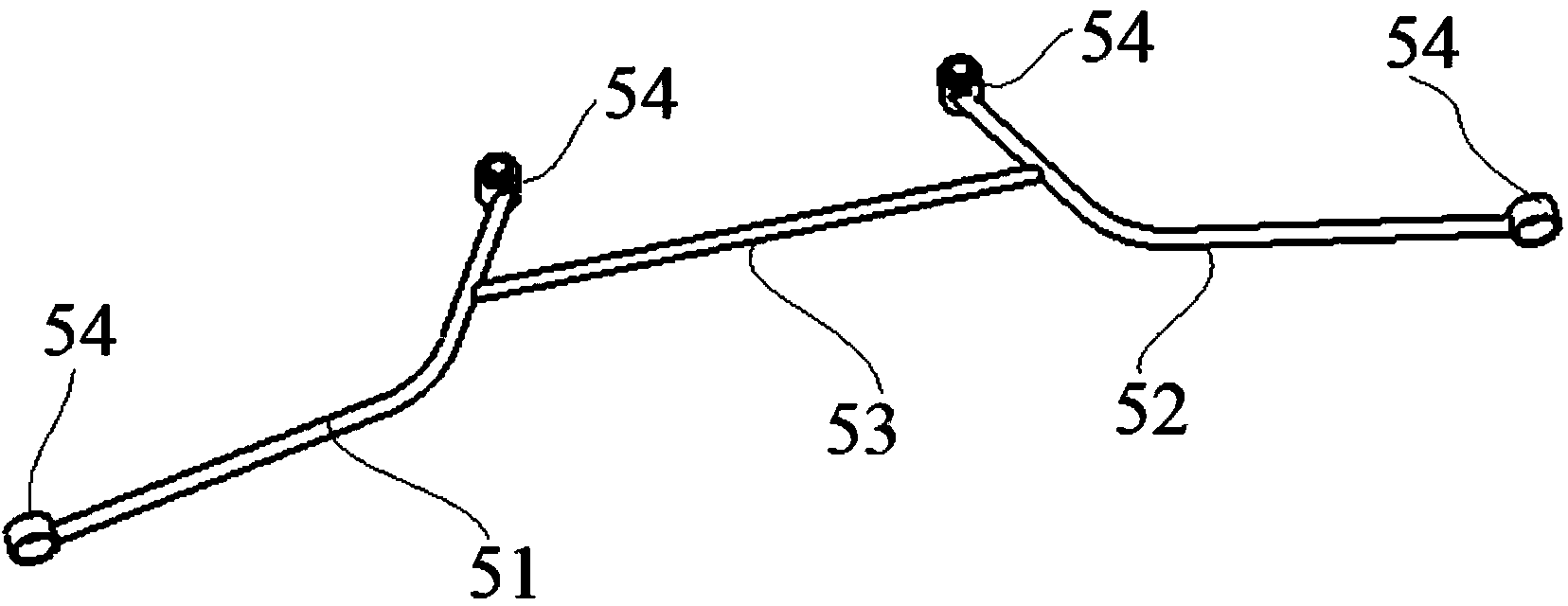

[0022] Such as Figure 1 to Figure 6 As shown, an automobile torsion beam suspension of the present invention is mainly composed of a suspension beam 2, a suspension longitudinal beam 1, a spring base 4, a shock absorber mounting bracket 6, a wheel mounting plate 8, a stabilizer cross bar 5 and other components. The suspension is symmetrical. The two suspension longitudinal beams 1 are respectively welded and connected to one end of the suspension beam 2, and the stabilizer beam 5 is located between the two suspension longitudinal beams 1 and is rotatably connected with the suspension beam 2 and the suspension longitudinal beam 1.

[0023] Specifically, the suspension beam 2 is a sheet metal stamped part, and the shape is an open U-shaped groove or a V-shaped groove. The thickness and shape of the sheet metal of the suspension beam 2 need to be determined according to the roll stiffness and strength requirements of the torsion beam suspension. The roll stiffness provided by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com