Damping modularized load bearing wheel set with three stages of balanced suspensions

A technology of balancing suspension and damping module, which is applied in the field of road wheel set and damping modular road wheel set, can solve the problem of reducing the service life of rubber crawler walking devices, increasing maintenance frequency and difficulty, and poor damping effect of balance suspension. and other problems, to achieve the effect of improving ride comfort and passability, improving ride comfort and passability, sealing and lubrication is simple and easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

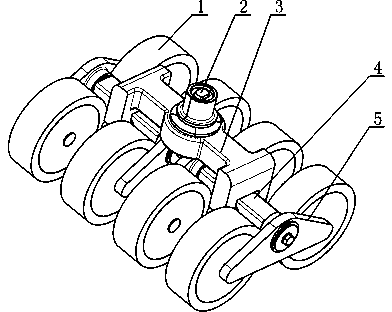

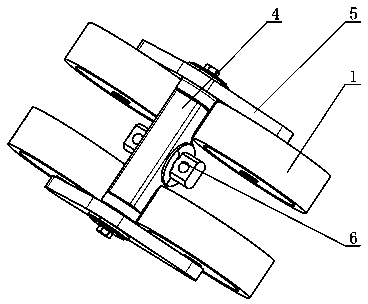

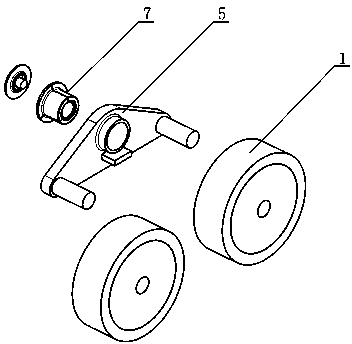

[0032] see figure 1 , Figure 7 , a shock-absorbing modular road wheel set with a three-stage balanced suspension, including a primary balanced suspension 3, a primary balanced suspension rubber ball joint 2, and two modular double-row road wheel assemblies; the The double-row road wheel assembly consists of two single-row road wheel assemblies, a secondary balance suspension 4, and a secondary balance suspension rubber bush 6; the single-row road wheel assembly consists of two road wheels, A three-stage balance suspension 5 and a three-stage balance suspension rubber bushing 7 are formed.

[0033] see figure 1 , in order to better illustrate the content of the present invention, it is agreed that the transverse direction is the direction of the road wheel axle, and the direction perpendicular to the road wheel axle and forming a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com