High-performance subsonic speed air inlet duct integrated with inner auxiliary air inlet duct

An air intake, high-performance technology, applied in the direction of the exhaust port of the power unit, can solve the problems of the unfavorable radar stealth performance of the aircraft, and achieve the effects of improving the radar stealth performance, improving the total pressure recovery coefficient, and reducing aerodynamic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

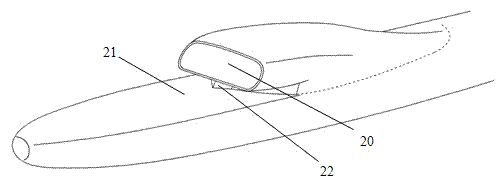

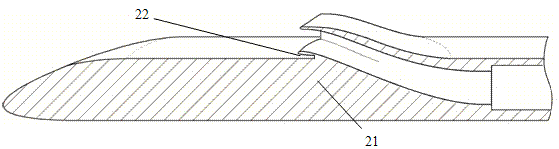

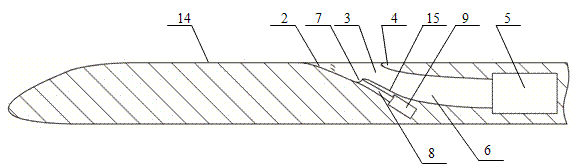

[0017] see image 3 , Figure 4 , Figure 5 As shown, it is the first embodiment of the high-performance subsonic inlet integrated with the auxiliary inlet in the present invention, and the main inlet in the first embodiment is a buried inlet. The subsonic inlet includes a main inlet and an auxiliary inlet. The main air intake comprises a main air intake 1, a main air intake deflector surface 2, a main air intake side wall 3, a main air intake lip 4, and an inner channel 6 of the main air intake connected to an aircraft engine 5. Described auxiliary air inlet comprises auxiliary air inlet 7 and auxiliary air inlet passage 8, and this auxiliary air inlet inner passage 8 is communicated with aircraft environment control system or cabin bleed air duct 9; Described auxiliary air inlet 7 can be positioned at The guide surface 2 of the main air inlet or / and the side wall 3 of the main air inlet. Specifically, if there is one auxiliary air inlet 7, it is arranged on the air guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com