A prestressed steel strand coil fixed and unwrapping device and its manufacturing method

A technology of prestressed steel strands and prestressed steel, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., and can solve problems such as direct measurement of payoff length, unfavorable payoff, and reduced work efficiency. Achieve the effects of suppressing non-directional ejection, simple and quick operation, and improving the efficiency of wire release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

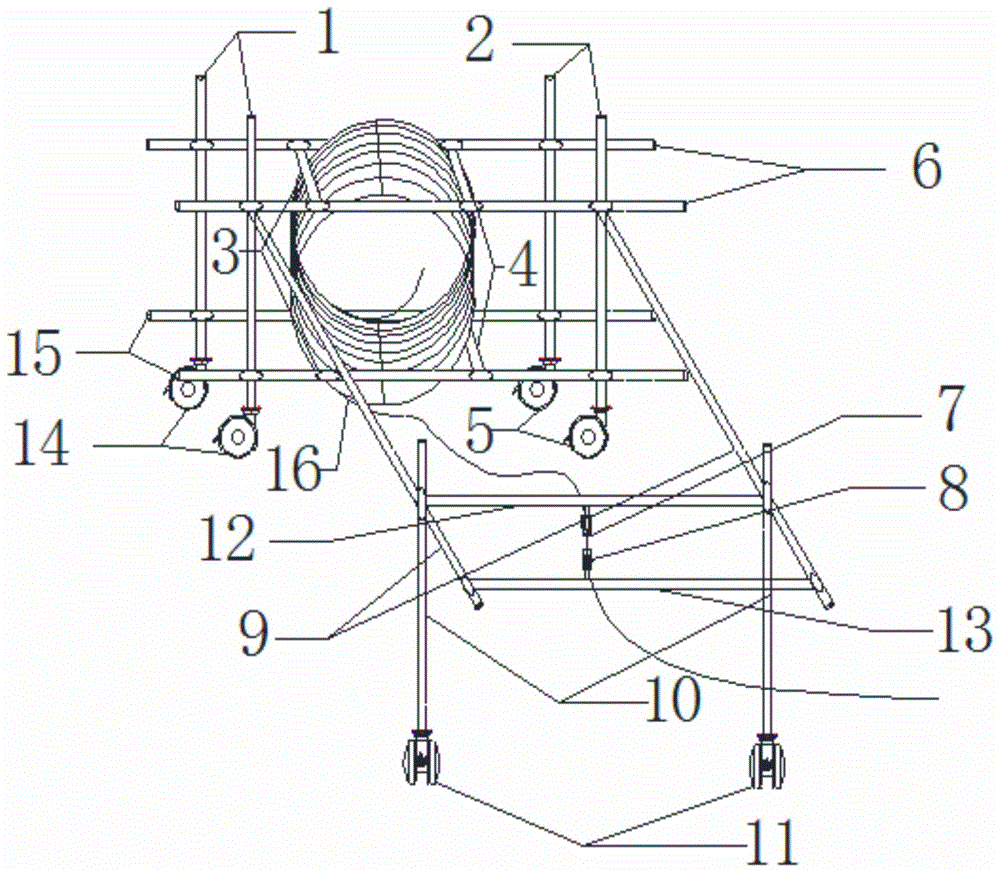

[0030] Such as figure 1 As shown, the steel strand fixing device of the present invention comprises an upper transverse connecting rod group 6, a lower transverse connecting rod group 15, a first vertical supporting rod group 1, a second vertical supporting rod group 2 and a first connecting rod group 3 , the main frame formed by the second connecting rod group 4; the longitudinal connecting rod group 9, the third vertical supporting rod group 10, the longitudinal connecting rod group 9 and the third vertical supporting rod group 10 are perpendicular to it and in the same plane The auxiliary bracket formed by connecting the first transverse connecting rod 12; and the second transverse connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com