Vortex pump impeller with groove structure

A swirl pump and impeller technology, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, can solve the problems of swirl pump lift, low efficiency, and hydraulic loss, and achieve lifting without overload performance, weight reduction, and shaft power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

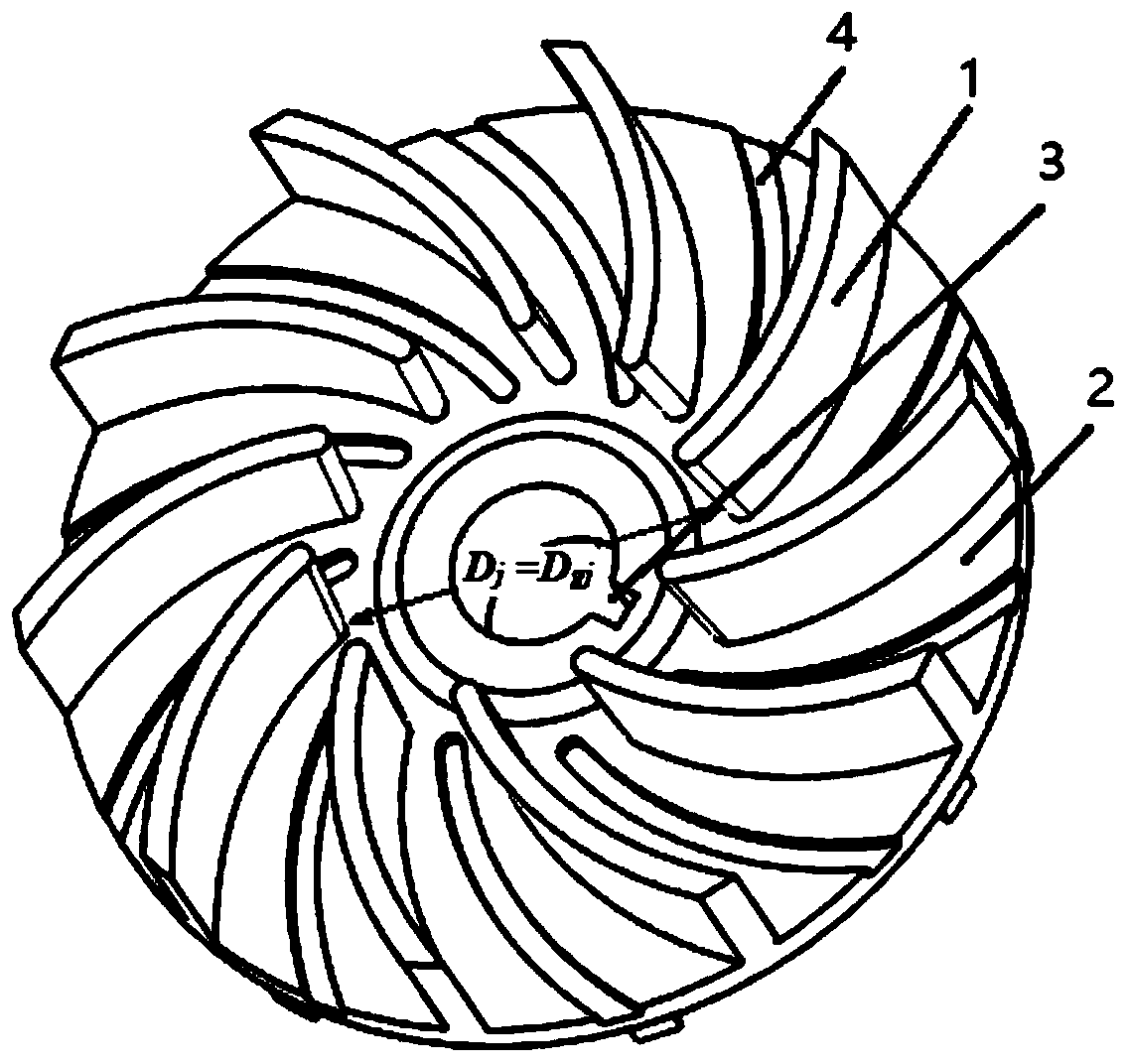

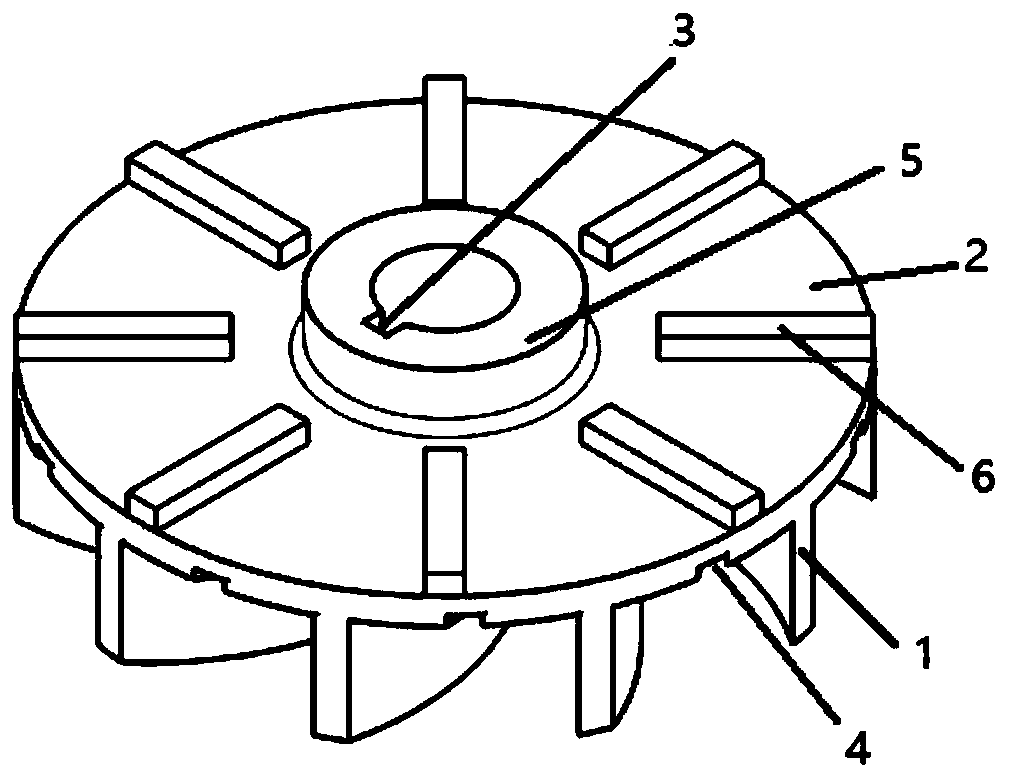

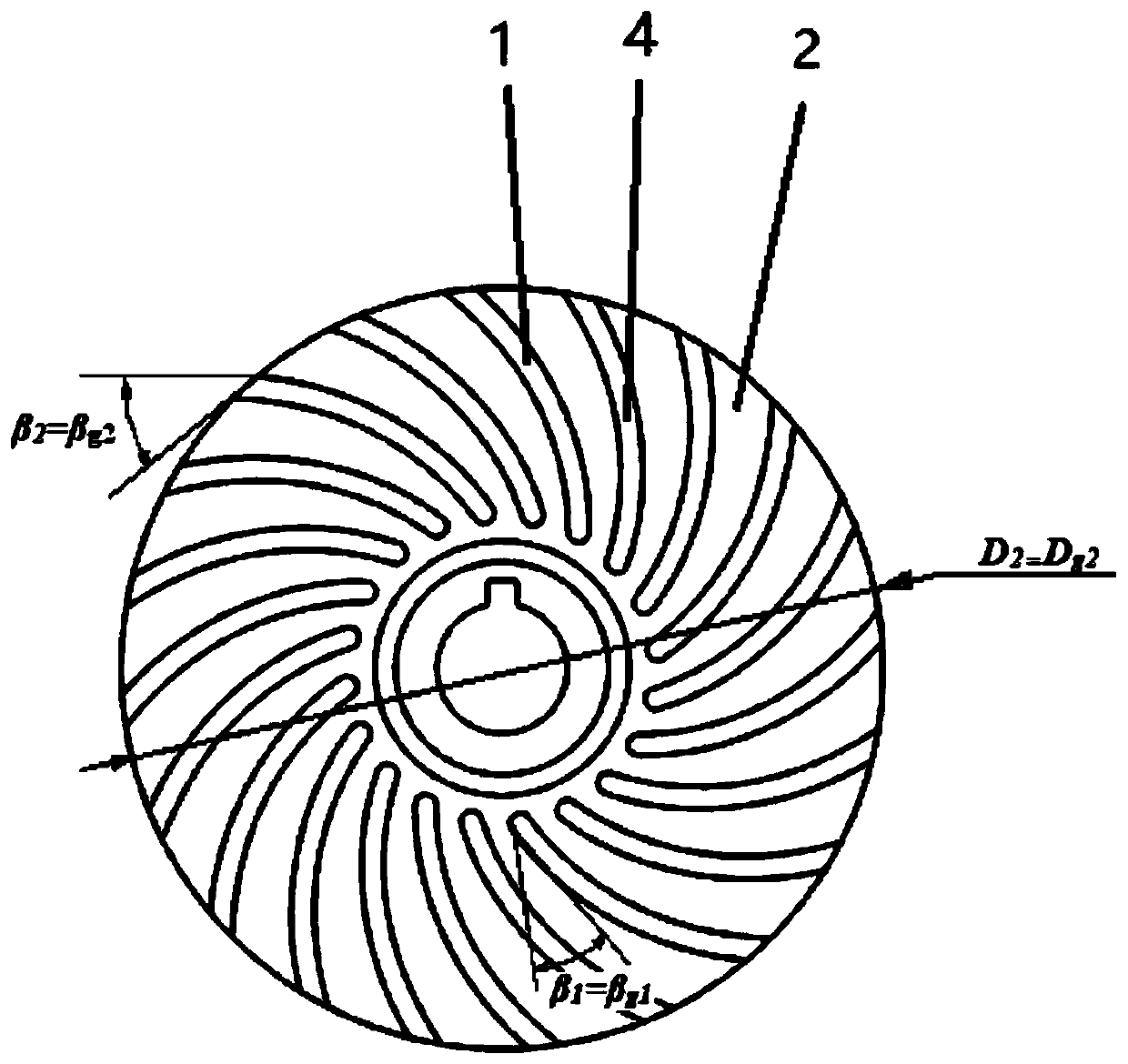

[0048] combine Figure 1-Figure 4 , the embodiment of the present invention discloses a swirl pump impeller with a groove structure, the impeller includes an impeller blade 1, a rear cover plate 2, a hub 5 and a back blade 6, and the impeller blade 1 is located on the rear cover plate 2, the back blade 6 is located on the other side of the rear cover 2, and the rear cover 2 is provided with a groove, and the groove is arranged in the blade flow channel between the impeller blades In the middle, the groove is consistent with the shape of the blade. The hub 5 is located at the center of the rear cover 2 , and the sidewall of the hub has a keyway 3 .

[0049] In this embodiment, the shape of the groove is consistent with the shape of the vane, and it is located in the middle of the flow path of the impeller. This structure can strengthen the confinement ability of the impeller to the fluid and improve the pumping capacity.

[0050] In some embodiments, the geometric parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com