Autotrophic denitrifying nitrogen-removal reaction device, denitrification system and denitrification method of denitrification system

A technology of nitrification and denitrification, autotrophic denitrification, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. To achieve the effect of convenient operation, efficient denitrification treatment, and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

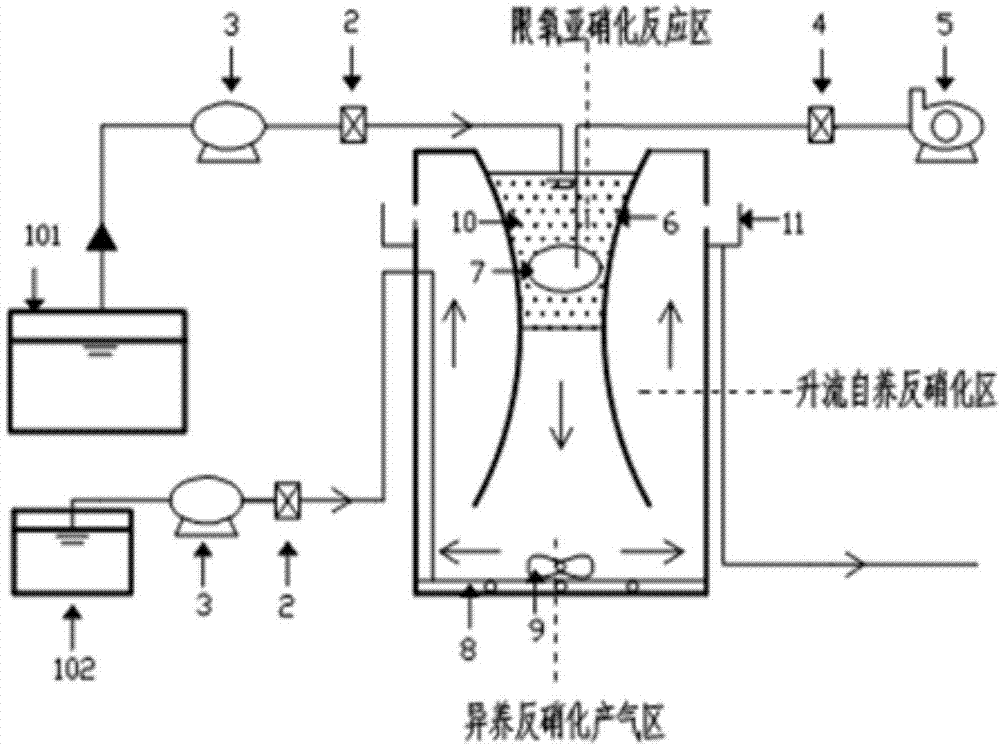

[0033] The present invention will be further described in detail in conjunction with the following specific embodiments and accompanying drawings. The process, conditions, experimental methods, etc. for implementing the present invention, except for the content specifically mentioned below, are common knowledge and common knowledge in this field, and the present invention has no special limitation content.

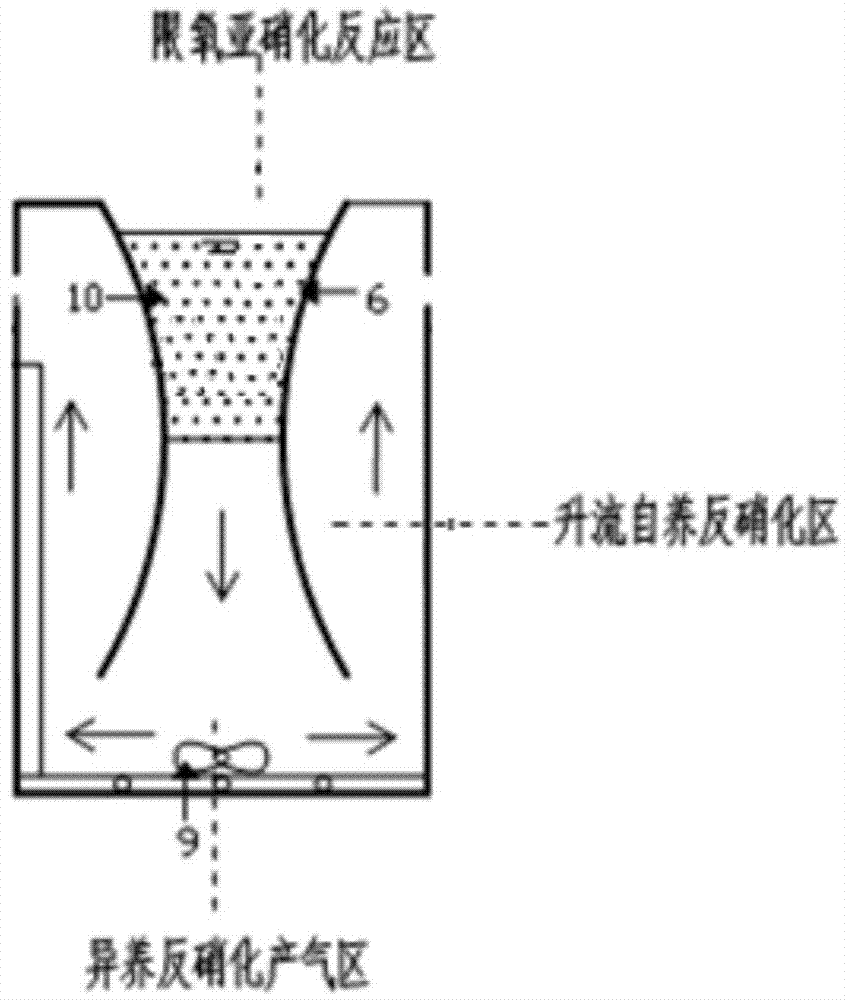

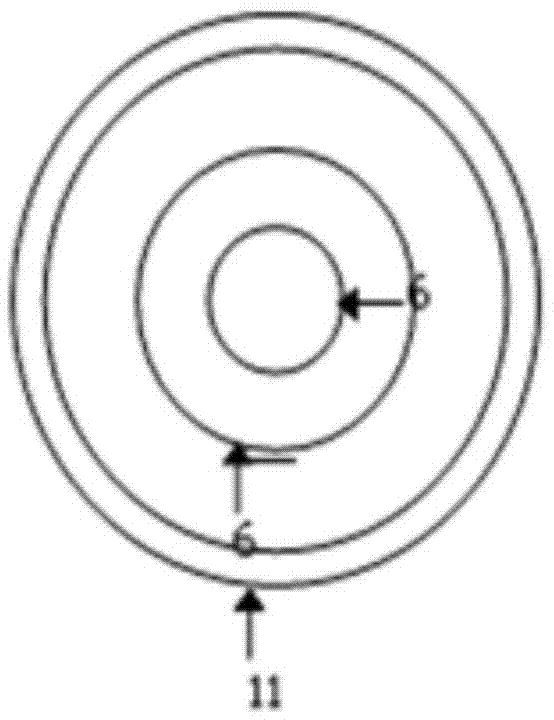

[0034] Such as figure 1 The shown autotrophic denitrification denitrification reaction device of the present invention includes a shell with a space inside the shell, and the space is divided into an oxygen-limited nitrosation reaction zone, a heterotrophic denitrification gas production zone and an upflow autotrophic denitrification zone. Area.

[0035] The housing is provided with a liquid inlet and several liquid outlets. The liquid inlet is connected to the oxygen-limited nitrosation reaction zone for feeding high ammonia nitrogen wastewater; the liquid outlet is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com