Polyhydroxyalkanoate-diatomite composite material as well as preparation method and application thereof

A technology of polyhydroxyalkanoates and composite materials, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve the complicated preparation method, single sewage treatment effect and high efficiency It can achieve the effect of simple and convenient preparation process, small pores and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

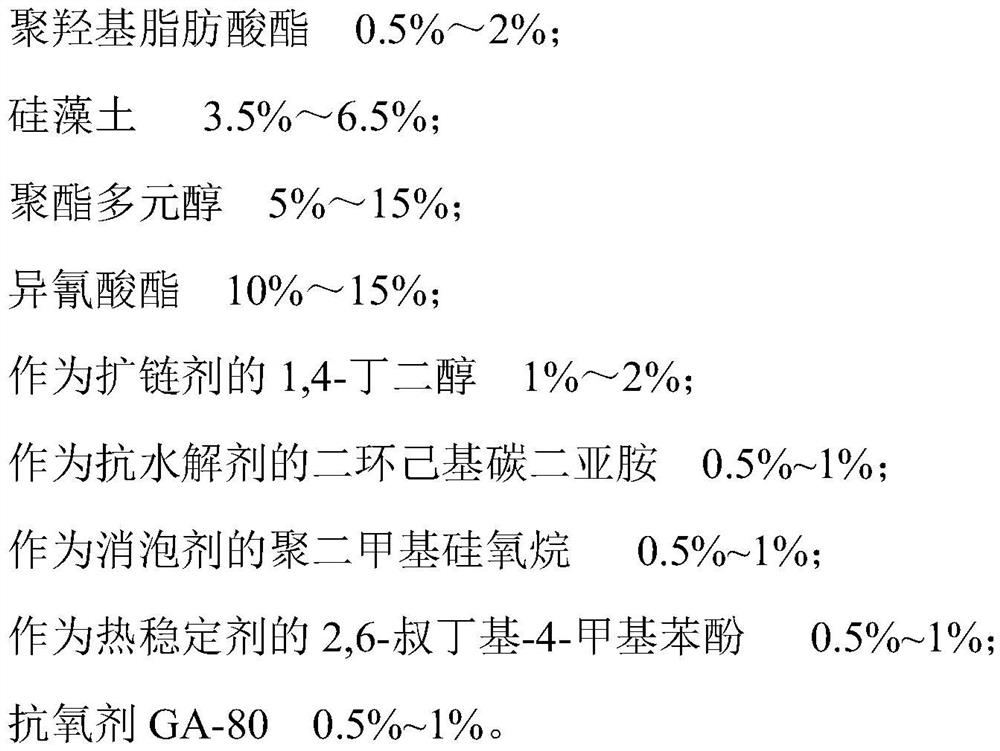

[0037] A polyhydroxyalkanoate-diatomite composite material provided in this embodiment comprises the following components in terms of mass fraction:

[0038] Polyhydroxyalkanoate 0.5%;

[0039] Diatomaceous earth 3.5%;

[0040] Poly-1,4-butylene adipate 5%;

[0041] Diphenylmethane diisocyanate 10%;

[0042] 1,4-Butanediol 1% as chain extender;

[0043] Dicyclohexylcarbodiimide 0.5% as antihydrolysis agent;

[0044] Dimethicone 0.5% as defoamer;

[0045] 2,6-tert-butyl-4-methylphenol as heat stabilizer 0.5%;

[0046] Antioxidant GA-80 0.5%.

[0047] The composite material is in the form of spherical particles with a particle size of 1 mm.

[0048] The preparation method of the polyhydroxyalkanoate-diatomite composite material provided by the present embodiment comprises the following steps:

[0049] S1: Dehydration pretreatment of poly-1,4-butylene adipate with a mass fraction of 5%, and preheating and melting of diphenylmethane diisocyanate with a mass fraction of 10%...

Embodiment 2

[0057] A polyhydroxyalkanoate-diatomite composite material provided in this embodiment comprises the following components in terms of mass fraction:

[0058] Polyhydroxyalkanoate 1.25%;

[0059] Diatomaceous earth 5%;

[0060] Poly(1,4-butylene adipate) 10%;

[0061] Diphenylmethane diisocyanate 12.5%;

[0062] 1,4-Butanediol 1.5% as chain extender;

[0063] Dicyclohexylcarbodiimide 0.75% as an antihydrolysis agent;

[0064] Polydimethylsiloxane 0.75% as defoamer;

[0065] 2,6-tert-butyl-4-methylphenol as heat stabilizer 0.75%;

[0066] Antioxidant GA-80 0.75%.

[0067] The composite material is in the form of spherical particles with a particle size of 1.5mm.

[0068] The preparation method of the polyhydroxyalkanoate-diatomite composite material provided by the present embodiment comprises the following steps:

[0069] S1: Dehydration pretreatment of poly-1,4-butylene adipate with a mass fraction of 10%, preheating and melting diphenylmethane diisocyanate with a mass...

Embodiment 3

[0077] A polyhydroxyalkanoate-diatomite composite material provided in this embodiment comprises the following components in terms of mass fraction:

[0078] Polyhydroxyalkanoate 2%;

[0079] Diatomaceous earth 6.5%;

[0080] Poly(1,4-butylene adipate) 15%;

[0081] Diphenylmethane diisocyanate 15%;

[0082] 1,4-Butanediol 2% as chain extender;

[0083] Dicyclohexylcarbodiimide 1% as antihydrolysis agent;

[0084] Dimethicone 1% as defoamer;

[0085] 2,6-tert-butyl-4-methylphenol as heat stabilizer 1%;

[0086] Antioxidant GA-80 1%.

[0087] The composite material is in the form of spherical particles with a particle size of 2mm.

[0088] The preparation method of the polyhydroxyalkanoate-diatomite composite material provided by the present embodiment comprises the following steps:

[0089] S1: Dehydration pretreatment of poly-1,4-butylene adipate with a mass fraction of 15%, preheating and melting diphenylmethane diisocyanate with a mass fraction of 15% at 50°C;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com