Hinged Hollow Slab Girder Bridge and Its Transverse Unbonded Post-tensioning Prestressed Construction Technology

A technology of hollow slab girders and hollow slabs, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as bridge deck pavement abutment piers, support damage, transverse connection damage between beams, and hinged concrete falling off, etc. To achieve the effect of increasing strength, strengthening lateral connection, and increasing overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

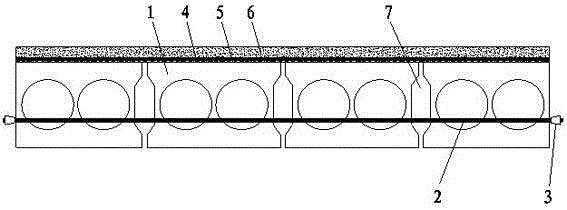

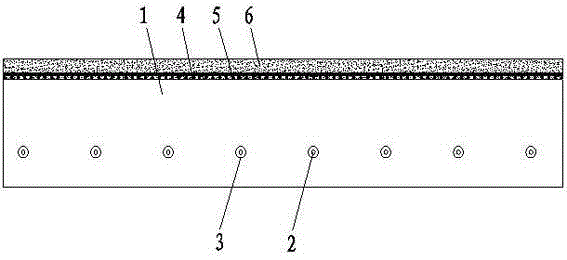

[0024] Embodiment one: if Figure 1~2 As shown, a hinged hollow slab girder bridge includes several hollow slabs 1 spliced together. The lower part of the side wall of the hollow slab 1 is uniformly distributed with several through holes along its length direction, and the through holes are connected with the hollow slabs. 1 The length direction is vertical, and steel strands 2 are arranged in the through holes, the length of the steel strands 2 is greater than the total width of the spliced hollow slabs, and the two ends of the steel strands 2 are respectively provided with anchors 3, The hinge joints 7 between the adjacent hollow slabs 1 are filled with concrete, and the upper surface formed by the spliced hollow slabs is evenly laid with several transverse steel bars 5 and longitudinal steel bars 4, and the upper surface is also covered with The concrete layer 6 wrapping the horizontal reinforcement 5 and the longitudinal reinforcement 4.

[0025] In this embodiment,...

Embodiment 2

[0029] Embodiment 2: A transverse non-bonding post-tensioning prestressed construction process of a hinged hollow slab girder bridge adopts the hollow slab 1 of the above structure, and proceeds according to the following steps:

[0030] (1) Install the prefabricated hollow slab 1, and align the through holes on the adjacent hollow slab 1;

[0031] (2) Apply lubricating and anti-corrosion materials to the sides of the steel strands for 2 weeks, then wrap them with plastic paper or sleeves, and then pass the treated strands 2 through the through holes;

[0032] (3) Cast-in-situ concrete in the hinge joint 7 of the adjacent hollow slab 1;

[0033] (4) After the strength of the hinged concrete reaches 75%, install anchors 3 at both ends of the steel strand 2 to tension the steel strand 2;

[0034] (5) After the tensioning is completed, the bridge deck pavement is carried out on the upper surface formed by the spliced hollow slabs 1. Concrete layer6.

[0035] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com