Practical and simple compaction degree measurement box for construction site

A technology of compactness and measurement box, which is applied in the field of foundation soil survey, infrastructure engineering, construction, etc. It can solve the problems that affect the construction progress, the time difference between the test data and the construction site, and the long delay time, so as to prevent loss and Omissions, time saving, and timely data provision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

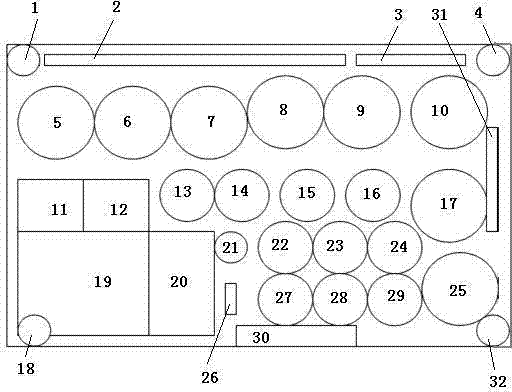

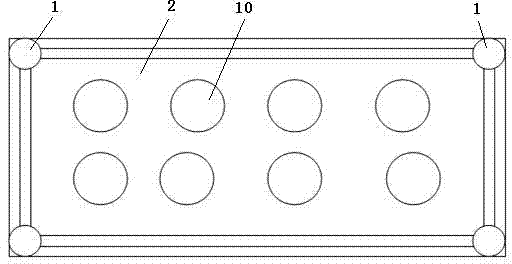

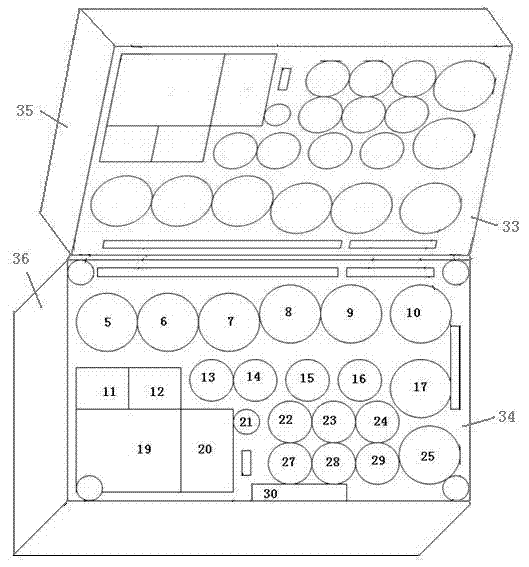

[0024] The drawings show a specific embodiment of the invention.

[0025] The present invention is a practical and simple compactness measuring box on site, including a suitcase and two upper and lower instrument templates installed in the suitcase, as well as test equipment for measuring compaction and moisture content, and the upper and lower two instruments The template is carved according to the outline of each test instrument and equipment for measuring compaction and moisture content. Each experimental instrument corresponds to the exclusive pits on the upper and lower instrument templates. The upper instrument template 33 is installed. In the opening cover 35 on the upper part of the suitcase, the lower instrument template 34 is placed in the box 36 at the lower part of the suitcase, and the upper and lower instrument templates are used for docking, so as to fix all the measured compactness and content from above and below. Test equipment for water volume.

[0026] Test ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com