Fast pile connecting method for prestressed concrete precast piles and lock-type connector pile

A technology of prefabricated concrete piles and prestressing, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc. It can solve problems such as anti-corrosion and difficult control of production tolerances, difficult mechanical inspection of welding quality, and difficult control of construction process quality. Achieve the effect of easy control of docking quality, reduce labor intensity of workers, improve labor efficiency and labor safety factor of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

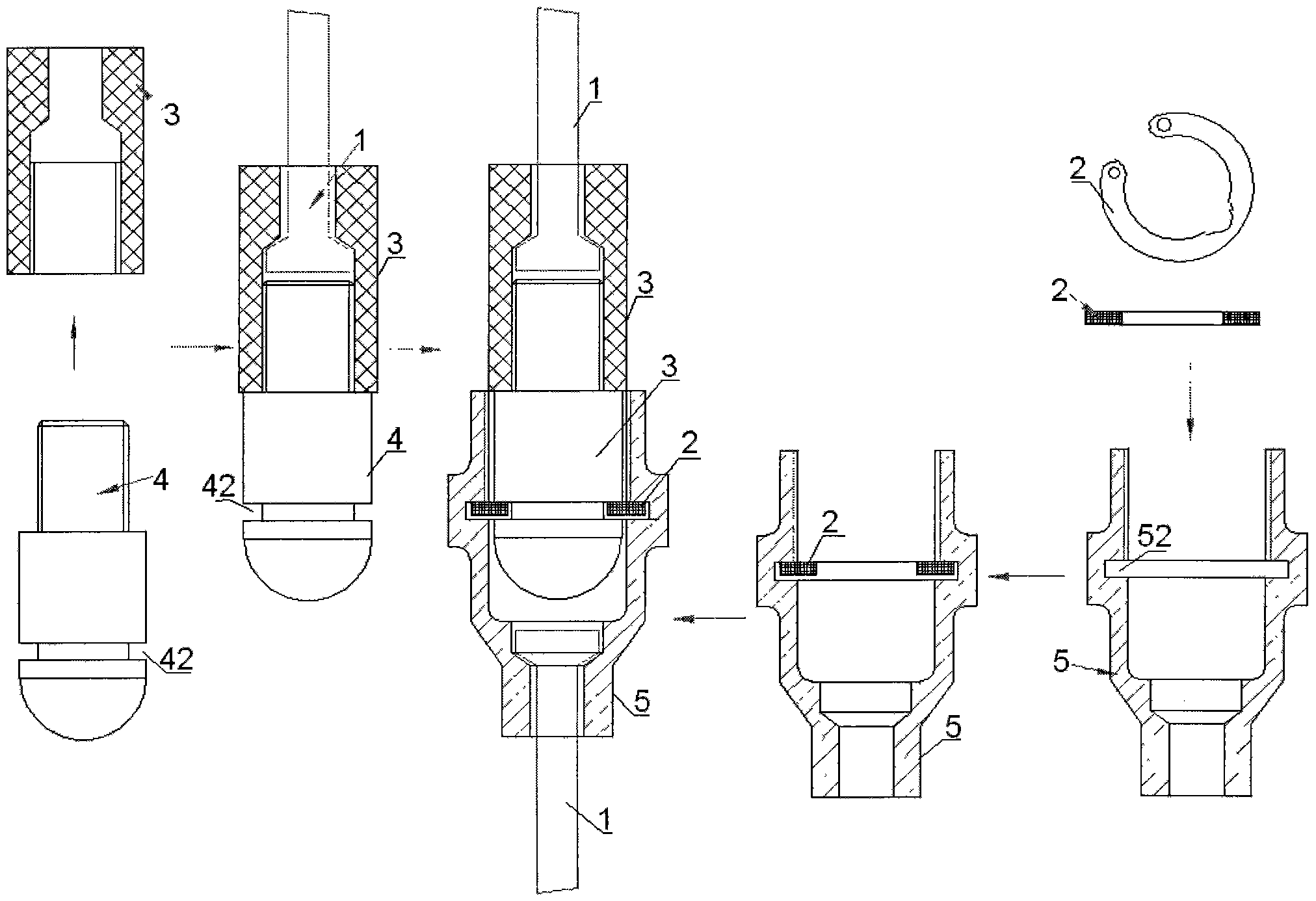

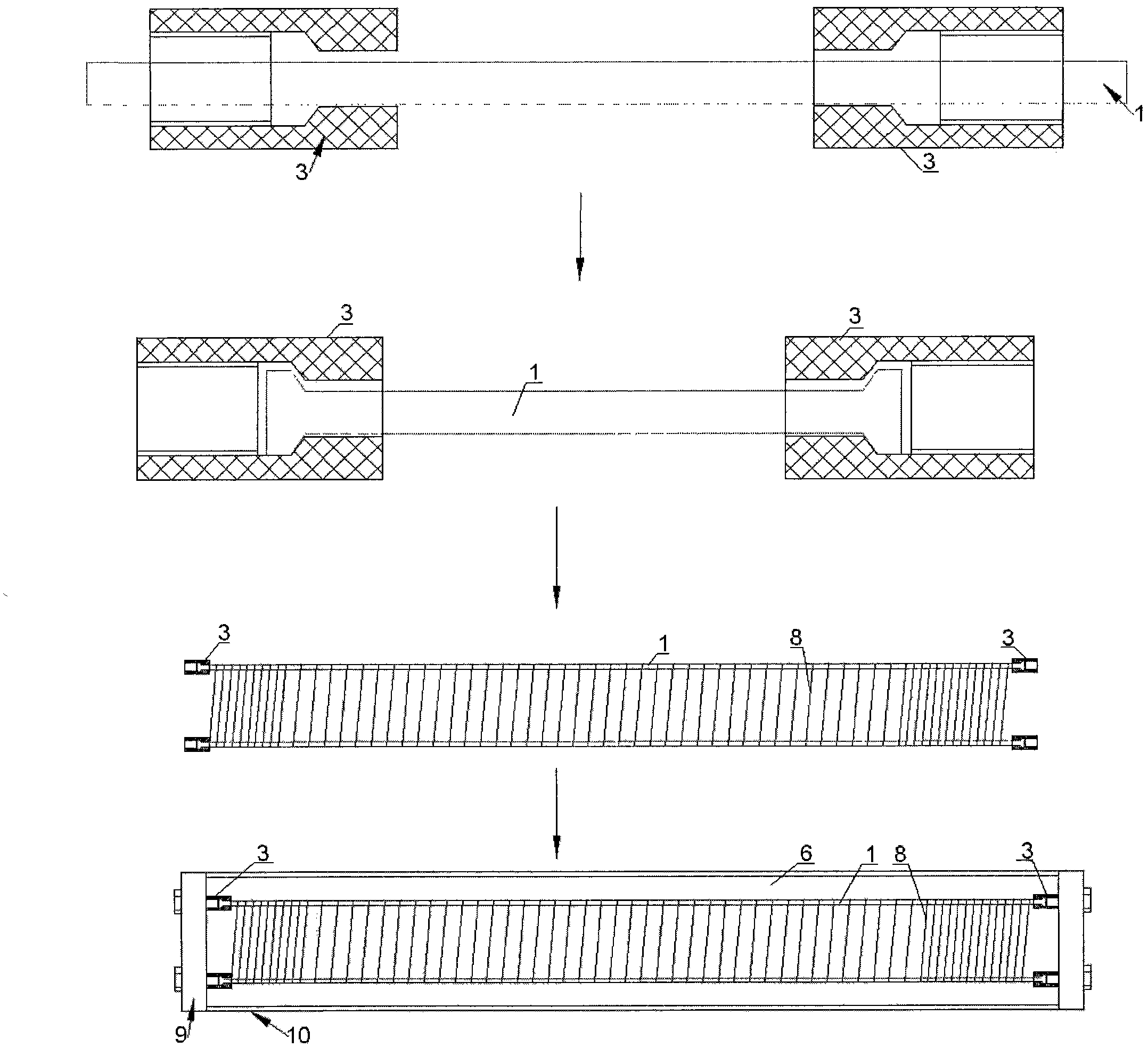

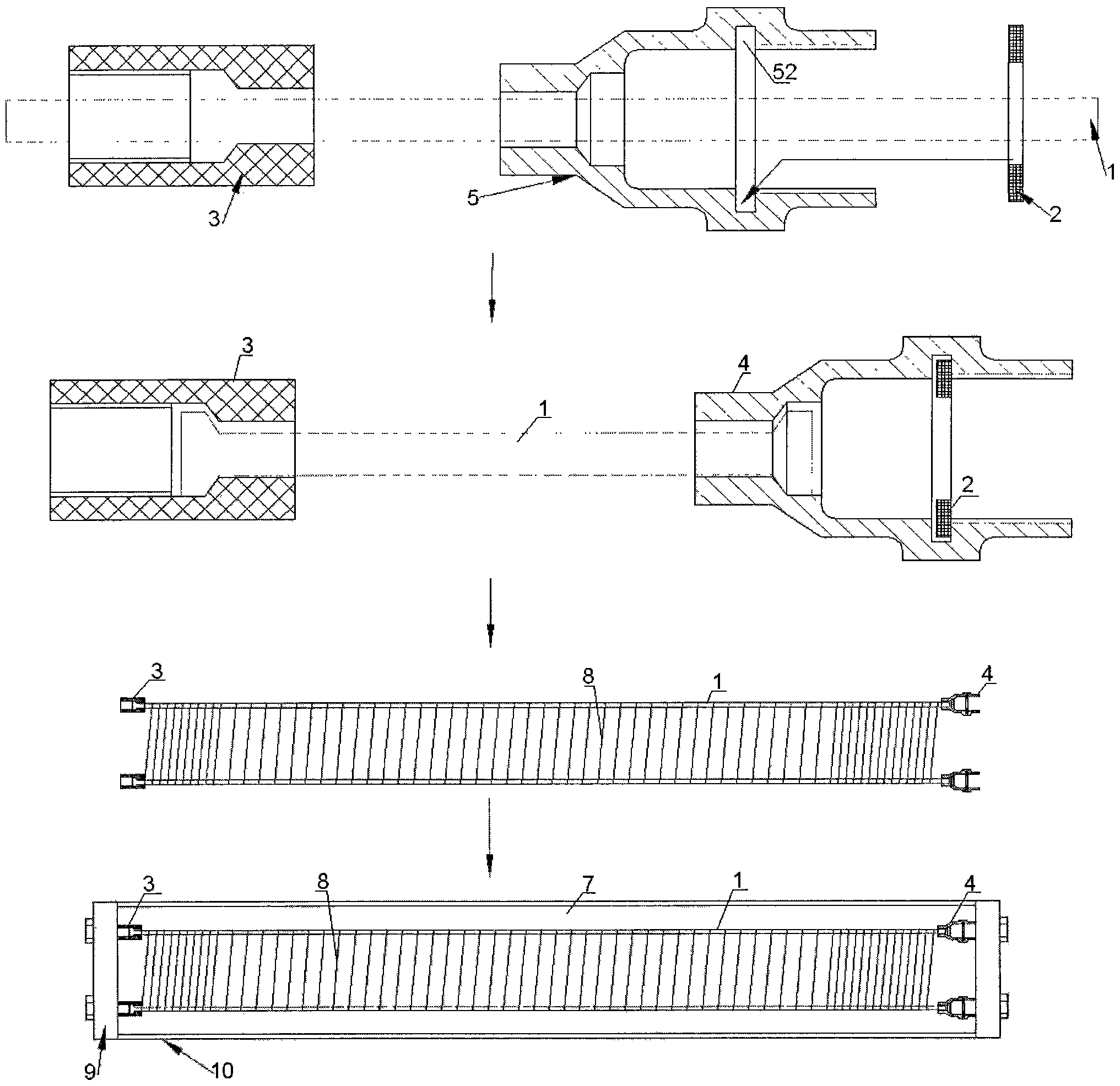

[0033] As shown in the figure, the method for quickly connecting the prestressed concrete precast piles of the present invention is that the upper section piles are connected to the lower section piles or the upper section piles are connected to the lower section piles, and the lower section piles are then connected to the lower section piles; the upper section piles are fixed connection The two ends of a plurality of steel rods arranged side by side with the annular spacing of the stirrups are respectively connected to the upper section pre-stressed concrete precast piles with the inner sleeve through the steel rod heading head and the inner sleeve mechanism is a steel cage; The two ends of the multiple steel rods distributed side by side are respectively connected by the steel rod heading to the inner sleeve joint mechanism and the outer sleeve joint mechanism as the lower section prestressed concrete precast piles of the steel cage; the butt joint of the prestressed concrete p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com