Buoy type deepwater single-wall steel cofferdam construction method

A construction method, the technology of steel cofferdam, applied in the direction of basic structure engineering, construction, etc., can solve problems such as rectification of subsidence, and achieve the effect of reducing workload, simple construction steps and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

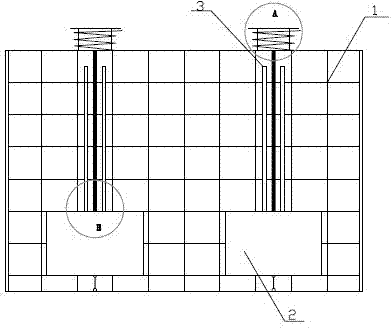

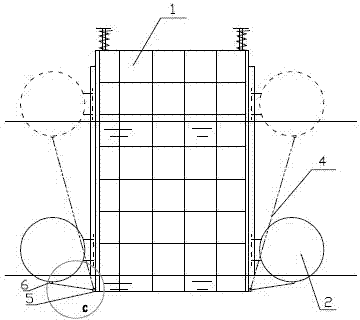

[0054] The present invention is described in further detail in conjunction with accompanying drawing now.

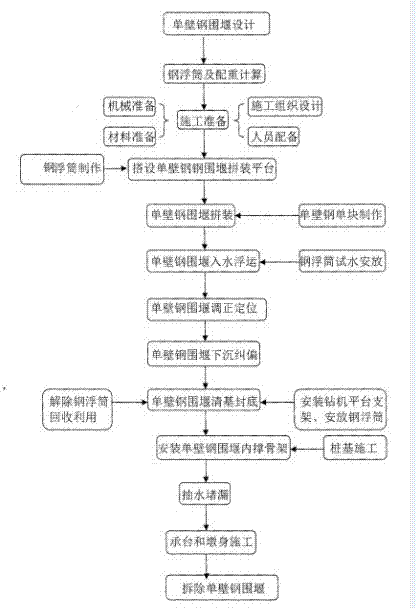

[0055] as attached Figures 1 to 6 Shown, a kind of construction method of deepwater single-wall steel cofferdam buoy method, this construction method comprises the following steps:

[0056] Step 1. Single-wall steel cofferdam design: According to the stress characteristics of the single-wall steel cofferdam construction process, it can be divided into two stages: the bottom concrete construction stage and the stage of pumping water in the single-wall steel cofferdam to the maximum water level difference inside and outside the single-wall steel cofferdam. The calculation content includes: lateral force calculation; panel, vertical support and horizontal internal support design; back cover concrete thickness design.

[0057] Step 2. Steel buoy and counterweight design: according to the buoyancy F of the steel buoy 浮 Greater than the sum of steel cofferdam weight and buo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com