A high-strength guardrail

A high-strength, guardrail technology, used in building structures, stepped structures, buildings, etc., can solve the problems of complex guardrail structure, high cost, and inability to increase the strength of guardrails, and achieve the effect of ensuring strength, concise components, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

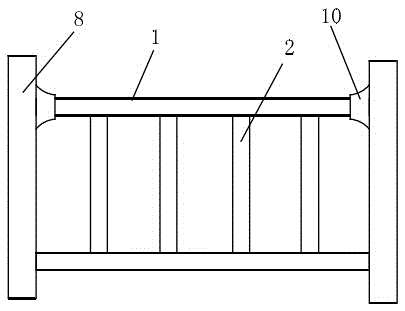

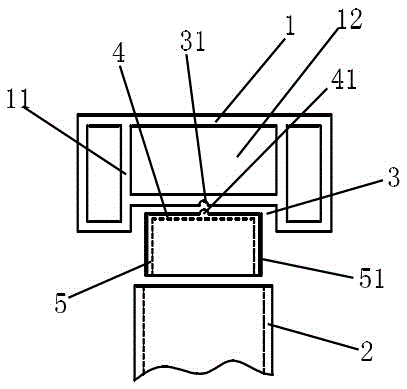

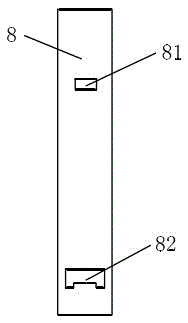

[0045] A high-strength guardrail, comprising a handrail 1, a lower link corresponding to the handrail 1, a plurality of railings 2 arranged between the handrail 1 and the lower link, and uprights 8 located at both ends of the handrail 1, characterized in that: the handrail 1 A mounting groove 3 adapted to the top of the railing 2 is provided at the bottom along the length of the handrail. The railing 2 is hollow to form an installation cavity. The mounting groove 3 is provided with a frame-shaped connector, and the frame-shaped connector includes a mounting on the top. The mounting plate 4 is fixed on the mounting groove 3 by screws, the frame-shaped connector is sleeved in the mounting cavity, the mounting groove 3 is a through groove, and the armrest 1 is hollow An armrest, the armrest 1 is provided with reinforcement ribs 11, a central cavity 12 is formed between the reinforcement ribs 11 and the hollow cavity wall of the armrest 1, and the upper part of the column 8 is provi...

Embodiment 2

[0048] The difference from the foregoing embodiment is that the limiting slot 31 is a single slot arranged on the same center line as the mounting slot 3, and the top surface of the mounting slot 3 is uniformly distributed with a grid line 32 along the limiting slot 31.

Embodiment 3

[0050] The difference from the above-mentioned embodiment is that the top surface of the mounting groove 3 is evenly distributed along the limiting groove 31 with equal dividing grooves 33 staggered with the limiting groove 31, and the top of the mounting plate 4 is provided with a dividing groove 33 Adapted evenly divided rib 42. The center of the mounting plate 4 is provided with a mounting hole for passing screws.

[0051] Due to the intersecting arrangement of the limit slot and the equalizing slot, it is ensured that the connecting piece will not rotate. In the design, the depth of the equalizing groove can be greater than the depth of the limiting groove, so that the positioning stability of the frame-shaped connector can be ensured under the premise of ensuring the strength of the armrest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com