High-stress floppy protruding thick coal seam large-diameter drilling device

A drilling device, high-stress technology, applied in the direction of safety devices, drilling equipment and methods, earthwork drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

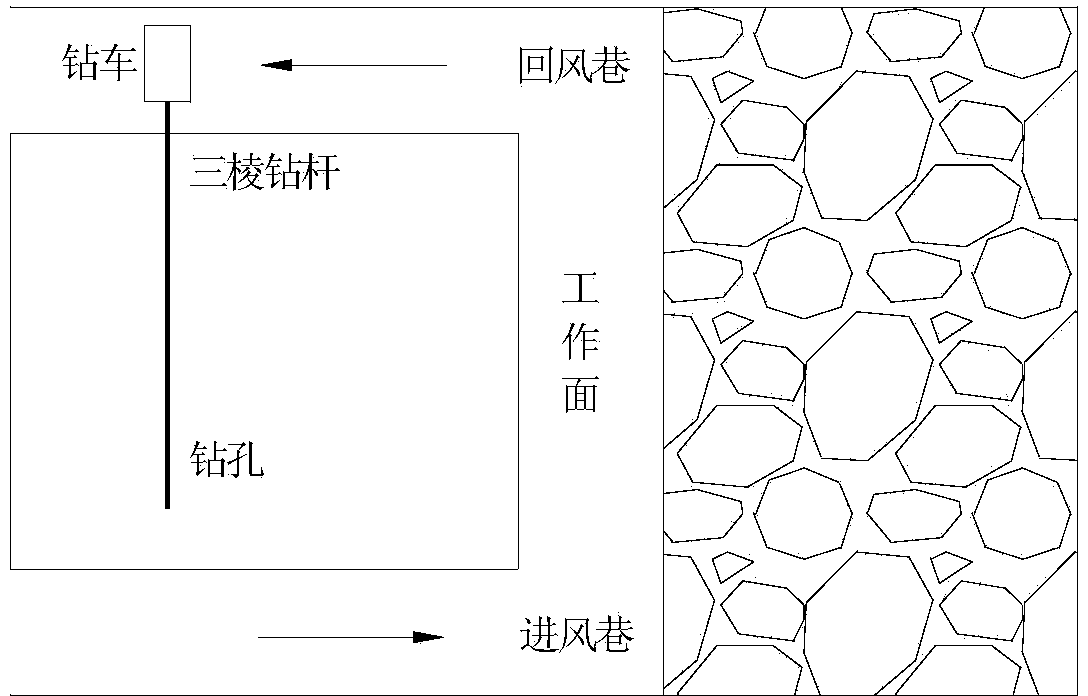

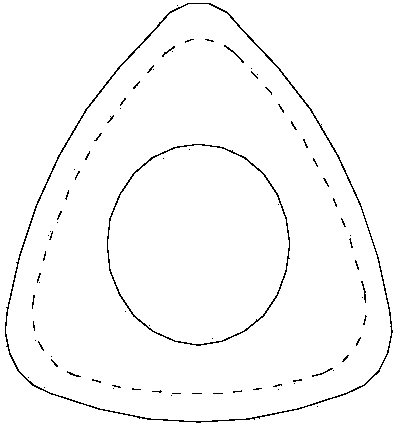

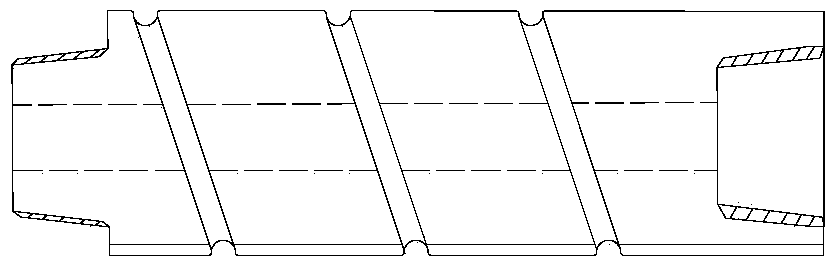

[0021] like figure 1 , figure 2 , image 3 As shown, the present invention first analyzes the characteristics of the soft coal seam, develops the double-arc groove three-edged drill pipe, and then analyzes the force of the double-arc grooved three-edged drill pipe with different diameters, and determines the double-arc grooved three-edged drill pipe with different diameters. The required torque of the rod, and then select the drill car according to the torque, and finally use the selected double-arc groove triangular drill rod and the drill car to complete the large-diameter drilling of the soft coal seam.

[0022] The high-torque new type drilling rig uses a hydraulic motor to drive the crawler and the drilling tool, and adopts a variable system, so that the no-load speed is fast, and the torque gradually increases as the speed decreases with the load change.

[0023] The large-diameter triangular drill rod is a double-arc groove triangular drill rod.

[0024] The six fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com