Pitching device for oil field staged fracturing

A ball-throwing device and staged fracturing technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of cumbersome operation process, limited number of balls, difficult operation, etc. Efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

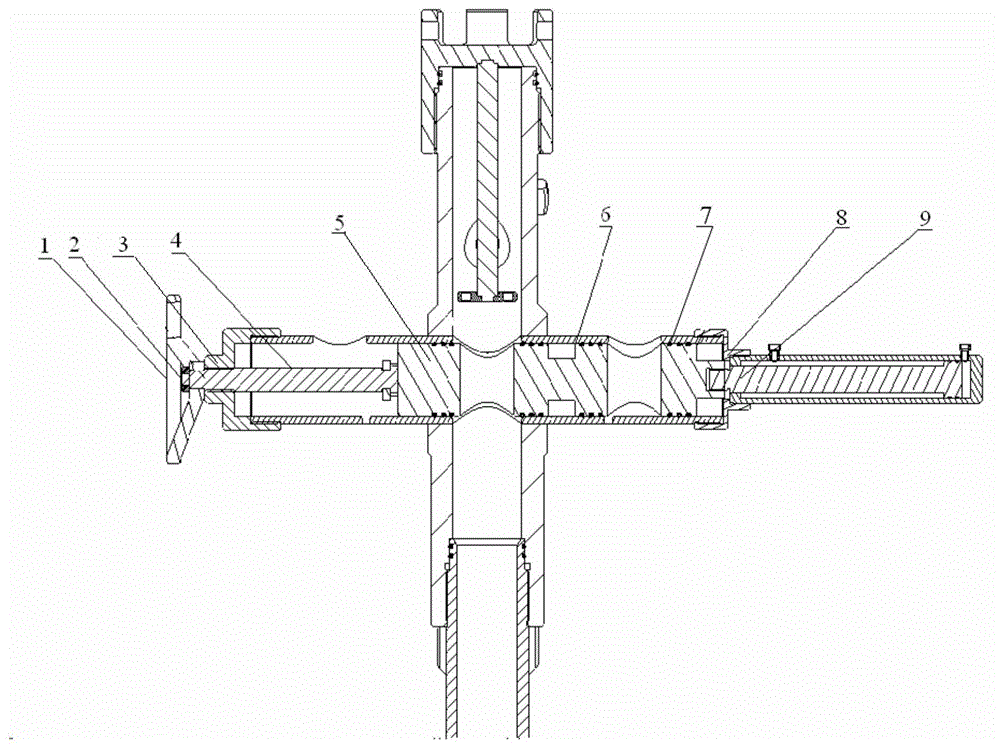

[0025] Such as figure 1 The shown pitching device for staged oilfield fracturing includes a rotating hand wheel 1, a lock nut 2, a screw cover 3, a push-pull rod 4, a ball pitching device 5, a ball pitching device body 6, a sealing ring 7, a hydraulic cylinder seat 8 and a hydraulic cylinder seat 8. Cylinder 9. Wherein, the rotating hand wheel 1 performs the ball throwing operation manually under the failure of the hydraulic cylinder; the lock nut 2 connects the rotating hand wheel 1 with the push-pull rod 4 and fixes it; 6; the push-pull rod 4 is connected with the rotating handwheel 1, and together with the rotating handwheel 1, manual pitching can be realized when the hydraulic cylinder cannot be used for pitching; When the device 5 reciprocates in the pitching hole, alternate pitching can be realized; the left and right ends of the top of the pitching device body 6 also have a pitching hole respectively, and the ball is thrown in the pitching device 5 through the pitching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com