Cutting tooth coal-cutting external spraying device of coal cutter

A technology of spraying device and shearer, which is applied in the direction of earth drilling and cutting machinery, etc., can solve the problems of waste of water resources, high labor intensity, long range, etc., and achieve water saving, labor reduction and flexible installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

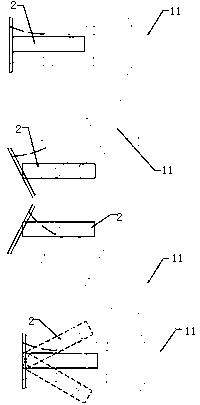

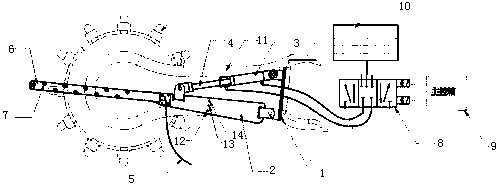

[0016] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The outer spraying device for cutting coal of the shearer pick of the present invention includes a lifting device and a spray pipe 6, wherein the lifting device includes a spray arm 2, a fixed arm 1 and a hydraulic cylinder 3, and the spray arm 2, the fixed arm 1 and the hydraulic cylinder 3 are in the form of Triangular arrangement, one end of the spray arm 2 is movably connected with one end of the fixed arm 1, the other end of the fixed arm 1 is movably connected with one end of the hydraulic cylinder 3, and the other end of the hydraulic cylinder 3 is provided with a piston rod 4, the The other end of the spray pipe 6 is movably connected with the piston rod 4; the lifting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com