Active-passive expansion hook type anchor rod

An active-passive, hook-type technology, applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of affecting the anchoring effect and safety, reducing the anchoring effect, disappearing, etc., to achieve the effect of ensuring the anchoring effect and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

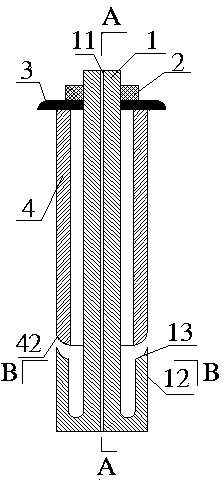

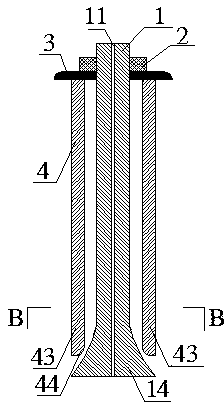

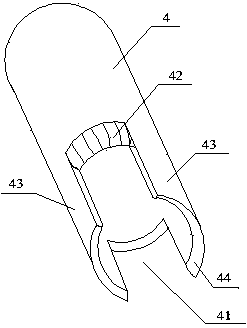

[0015] According to the drawings, the casing body 4 of the present invention is set on the outside of the rod body 1, and a tray 3 and a nut 2 are arranged on the head, and the tray 3 can transmit the tightening force of the nut 2 to the casing body 4 and the rock and soil around the borehole. , the nut 2 is connected to the rod body 1 through threads, and the rod body 1 will move toward the nut 2 relative to the casing body 4 during the tightening process of the nut 2 . Two casing notches 41 and two passive expansion fins 43 are provided at the tail of the casing body 4, the depth of the casing notch 41 is consistent with the length of the passive expansion fins 43, and the bottom of the casing notch 41 is at the bottom of the casing. The outer side of the main body 4 is provided with an active expansion support arc 42 , and the inner side of the tail of the passive expansion wing 43 is provided with a passive expansion wing arc 44 . The tail of the rod body 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com