An automatic capping device for radioactive sample bottles

A sample bottle and radioactive technology, applied in threaded caps, bottle/container caps, packaging, etc., can solve the problems of complicated manipulator operation, high price, troublesome maintenance, etc., and achieve the effect of facilitating maintenance, avoiding pollution, and preventing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

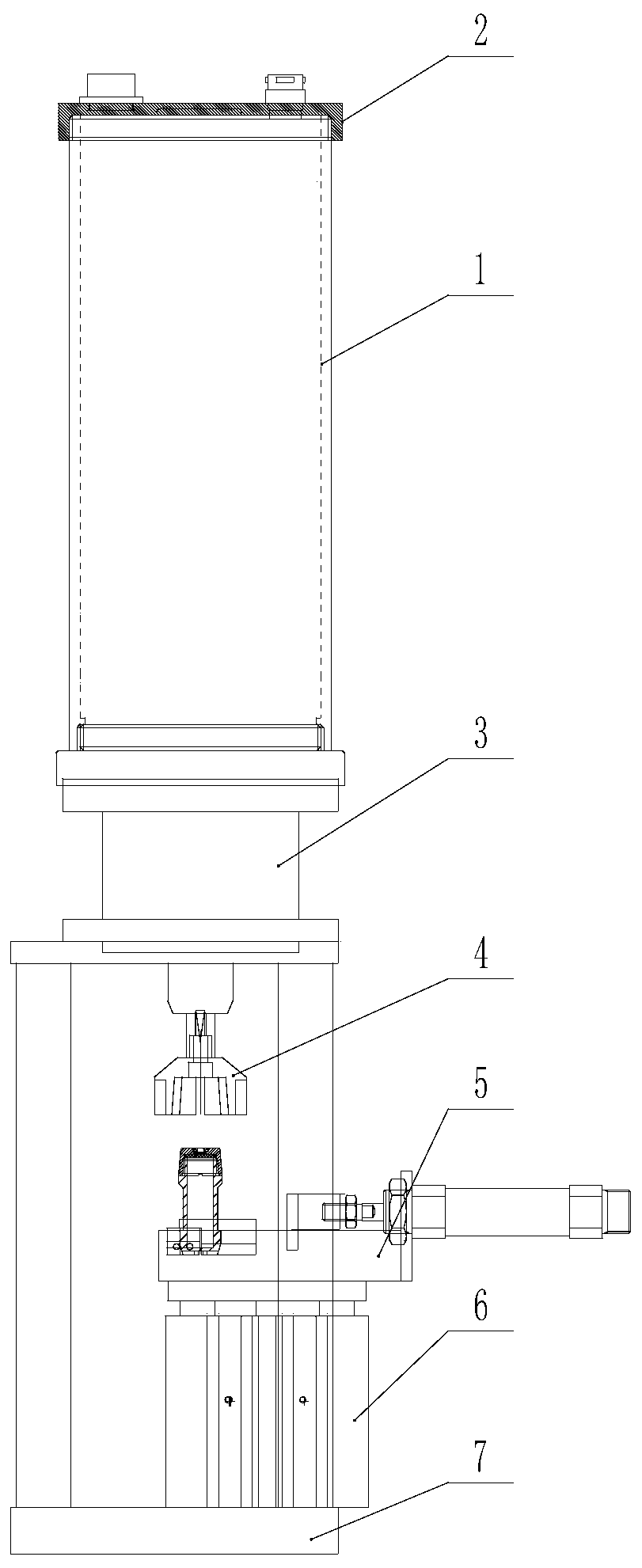

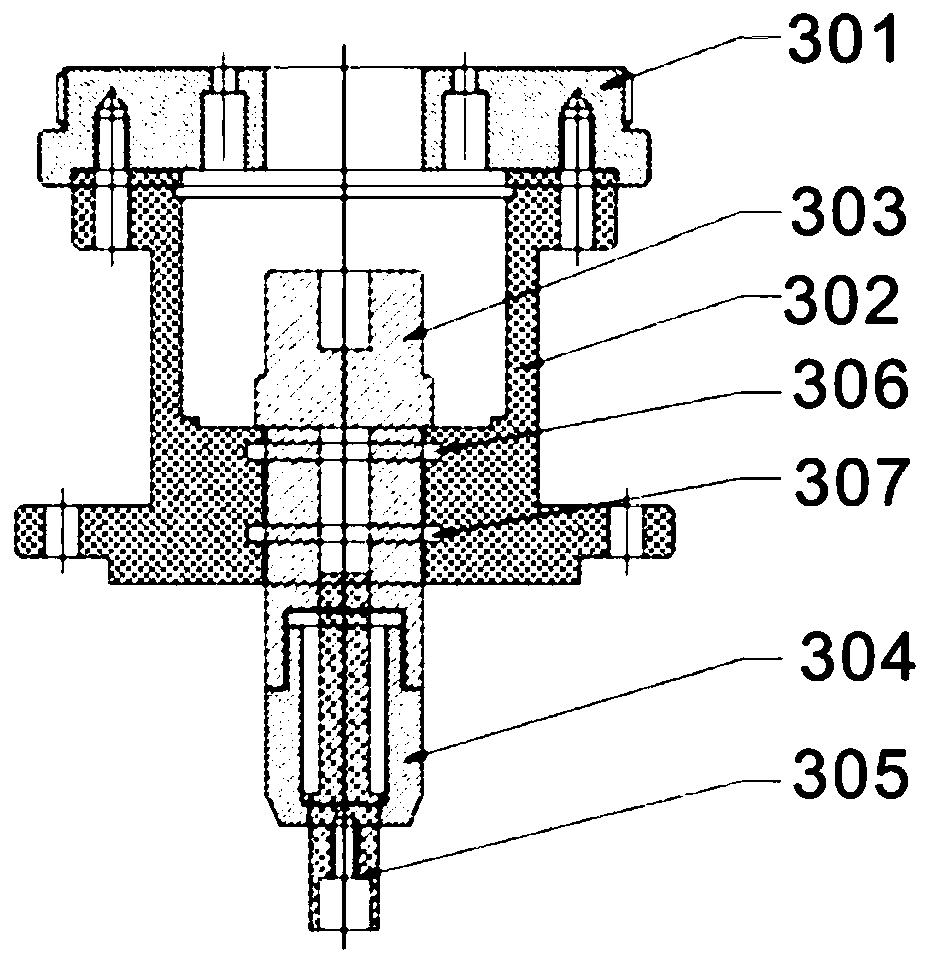

[0027] Such as figure 1 As shown, the present invention provides an automatic capping device for radioactive sample bottles, including a power source, a shaft coupling 3, a capping head 4, a clamping part 5 and a lifting part 6; the power source is driven by a shaft coupling 3 The cap opening head 4 rotates; the clamping part 5 and the lifting part 6 act on the container to be uncapped to cooperate with the rotation of the cap opening head 4 to separate the lid of the container to be uncapped from the container body.

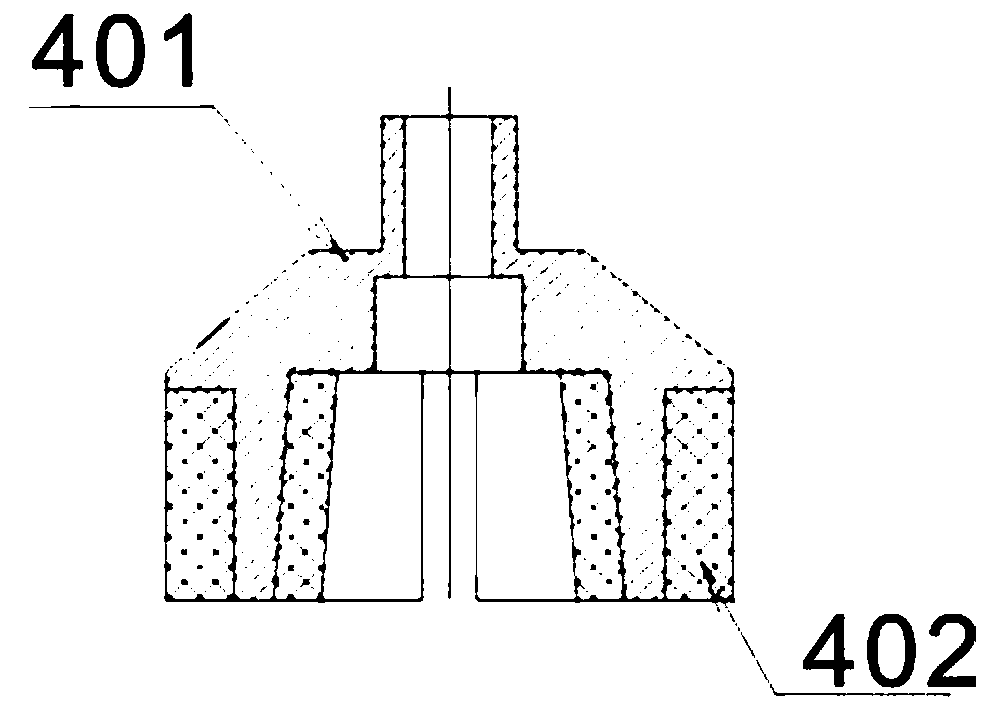

[0028] The cap opening head 4 includes a skeleton 401 and an elastic friction member 402 at least partially covering the skeleton 401; the elastic friction member 402 can clamp the lid after being squeezed and deformed by the lid. The elastic friction part is made of polyurethane material. In this embodiment, a stainless steel frame i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com