Balanced type double-row large-displacement axial plunger pump

An axial plunger pump, large displacement technology, applied in the direction of variable capacity pump components, pumps, multi-cylinder pumps, etc., can solve the problem of increasing the power density of the plunger pump and increasing the overturning moment of the cylinder block and the drive shaft. , Plunger pump self-priming and other problems, to achieve the effect of small size, improve power density, reduce flow pulsation and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

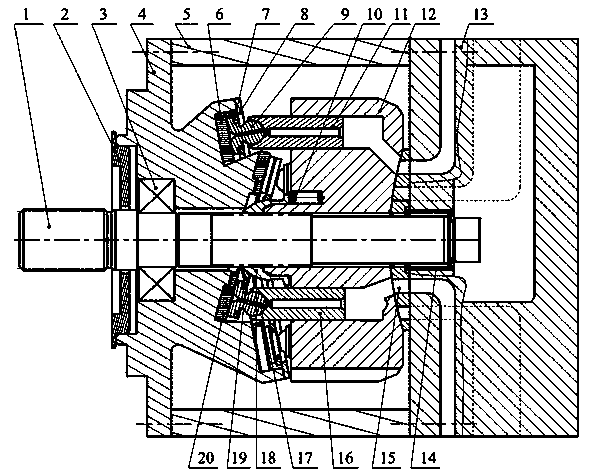

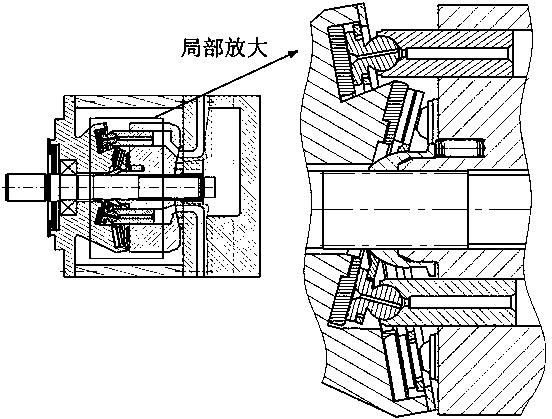

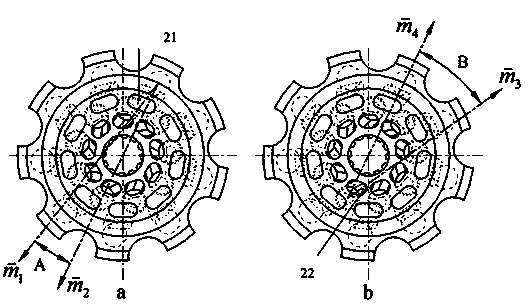

[0050] see figure 1 and Figure 5 , a balanced double-row large-displacement axial piston pump, including a drive shaft 1, a swash plate 4, an intermediate pump body 13 and a housing 5 between the two, and the housing is also provided with a swash plate Cooperate with the cylinder body 12 that is used to drive the drive shaft 1 to rotate. A flow plate 15 is also arranged between the cylinder body 12 and the middle pump body 13. The surface of the swash plate 4 opposite to the cylinder body is provided with cross-shaped The inner slope 25 and the outer slope 24 of the X type, the inner slide shoe 17 and the outer slide shoe 9 are respectively positioned on the inside slide surface 25 and the outer slide surface 24, and the inside slide shoe 17 and the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com