Composite stainless steel tube

A stainless steel pipe and stainless steel technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of heavy maintenance workload, easy corrosion of the inner wall, etc., and achieve the effect of weight reduction and weldability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

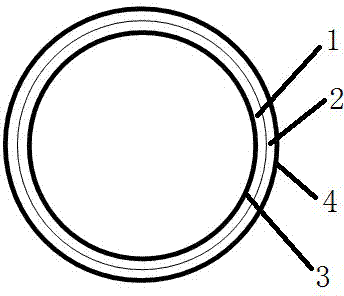

[0010] Such as figure 1 As shown, the composite stainless steel tube of the present invention includes a hollow stainless steel inner tube 1 and an aluminum alloy outer tube 2 sleeved on the hollow stainless steel inner tube 1, and the inner wall of the hollow stainless steel inner tube 1 is provided with an anti-corrosion coating 3, The outer wall of the aluminum alloy outer tube 2 is provided with a wear-resistant coating 4 . The cross-sectional shapes of the hollow stainless steel inner tube 1 and the aluminum alloy outer tube 2 are the same, which are circular, square or irregular circular.

[0011] The embodiment of the present invention has been described in detail above in conjunction with the accompanying drawings, but the present invention is not limited to the above embodiment, within the scope of knowledge possessed by those of ordinary skill in the art, it can also be done without departing from the gist of the present invention. Various changes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com