Water pipe vortex fire grate biomass particle boiler

A biomass particle and water pipe technology, applied in the field of boilers, can solve the problems of large electricity load, pollution, poor heating effect, etc., and achieve the effects of sufficient fuel, high thermal efficiency, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

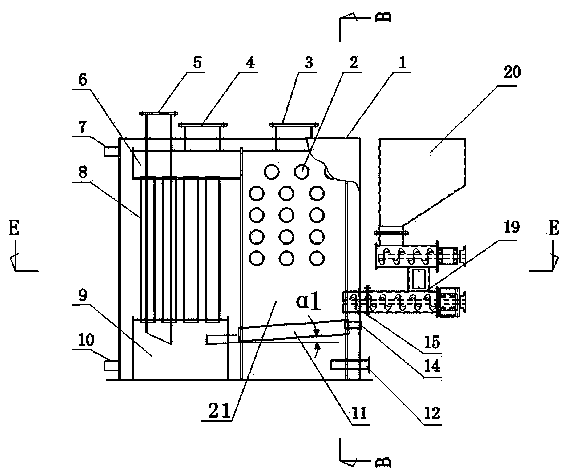

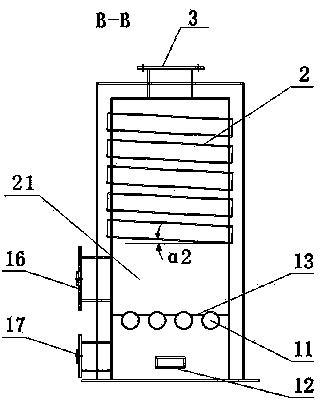

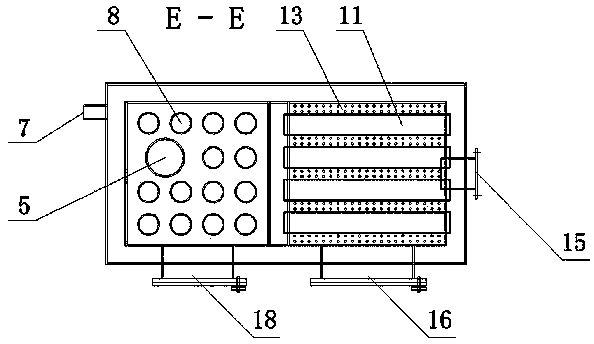

[0015] Embodiments, with reference to the accompanying drawings, a water tube vortex grate biomass pellet boiler, including a furnace body 1, a fuel bucket 20 and a fuel conveyor 19, is characterized in that the upper part of the furnace 21 on the right side of the furnace body 1 is evenly equipped with Fifteen water pipes 2, a row of four water pipe grates 11 are evenly installed in the lower part of the furnace 21, and the water pipe grate 11 is connected with a water pipe grate connecting plate 13, and a plurality of through holes are arranged on the water pipe grate connecting plate 13 13-1; the upper left side of the furnace body 1 is provided with an upper smoke chamber 6, and the lower part is provided with a lower smoke chamber 9; the upper smoke chamber 6 and the lower smoke chamber 9 are connected with fourteen smoke pipes 8; Chimney 5 is housed in the middle of 8. Evenly in the chimney 5, five water pipes 5-1 for improving thermal efficiency are vertically installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com