Dynamic viscosity measurement-based method for detecting corrosion resistance of refractory material

A refractory material and dynamic measurement technology, applied in the field of refractory materials, can solve problems such as the inability to reflect the real erosion condition, and achieve the effect of instantaneousness and authenticity, true and accurate results, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

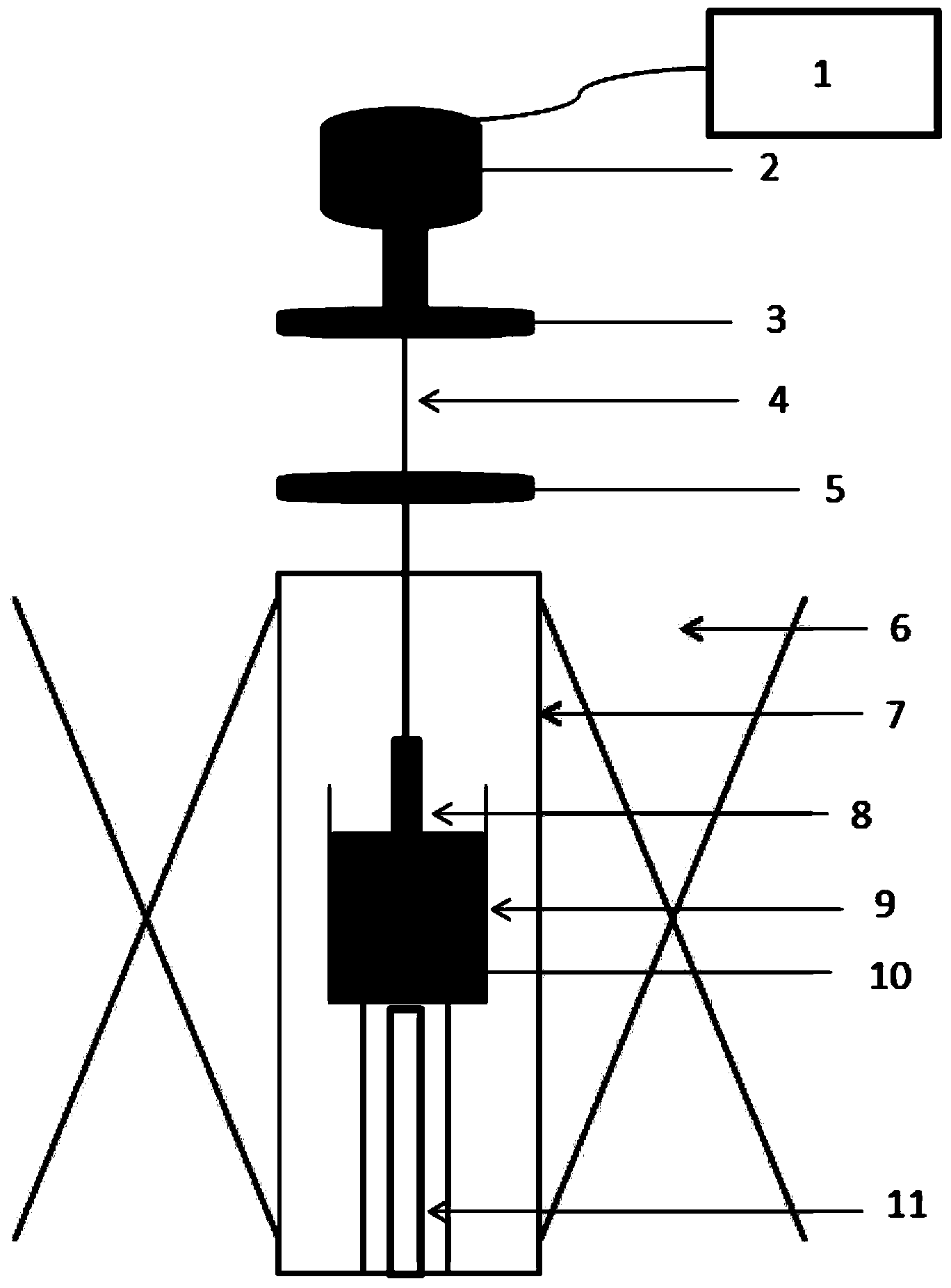

[0036] Embodiment 1: experiment determines the relation of viscosity and radius

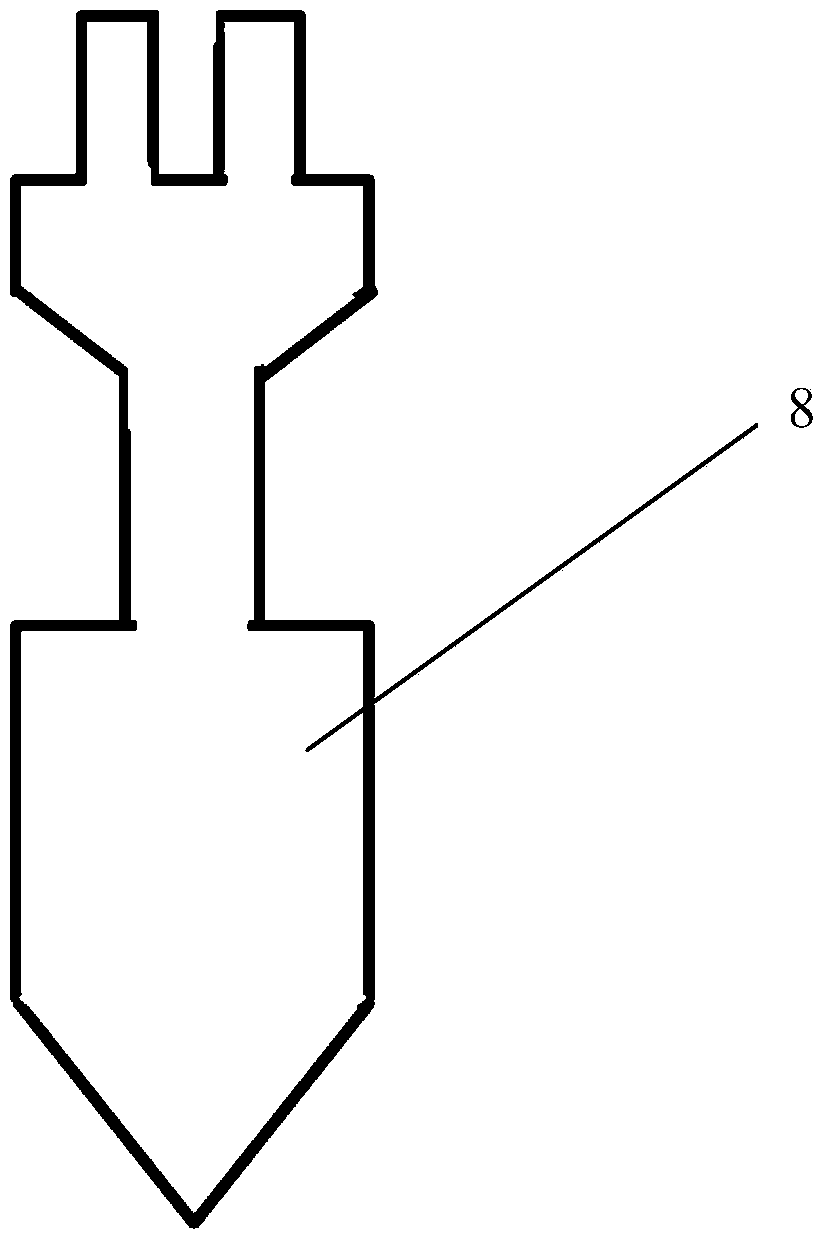

[0037] 1) Cut aluminum refractories into figure 2 Refractory measuring head of the shape shown, the chemical composition of the refractory is CaO:1.1%, SiO 2 :12.0%,Al 2 o 3 : 85.1%, FeO: 0.4%. The radius of the cylindrical part of the refractory measuring head is 10.2cm, 9.5cm, 8.5cm, 7cm, 5cm in sequence.

[0038] 2) Take 10.2cm as the initial radius of the refractory measuring head, and the mass of other radii reduced relative to the initial radius is taken as the erosion amount and added to the slag.

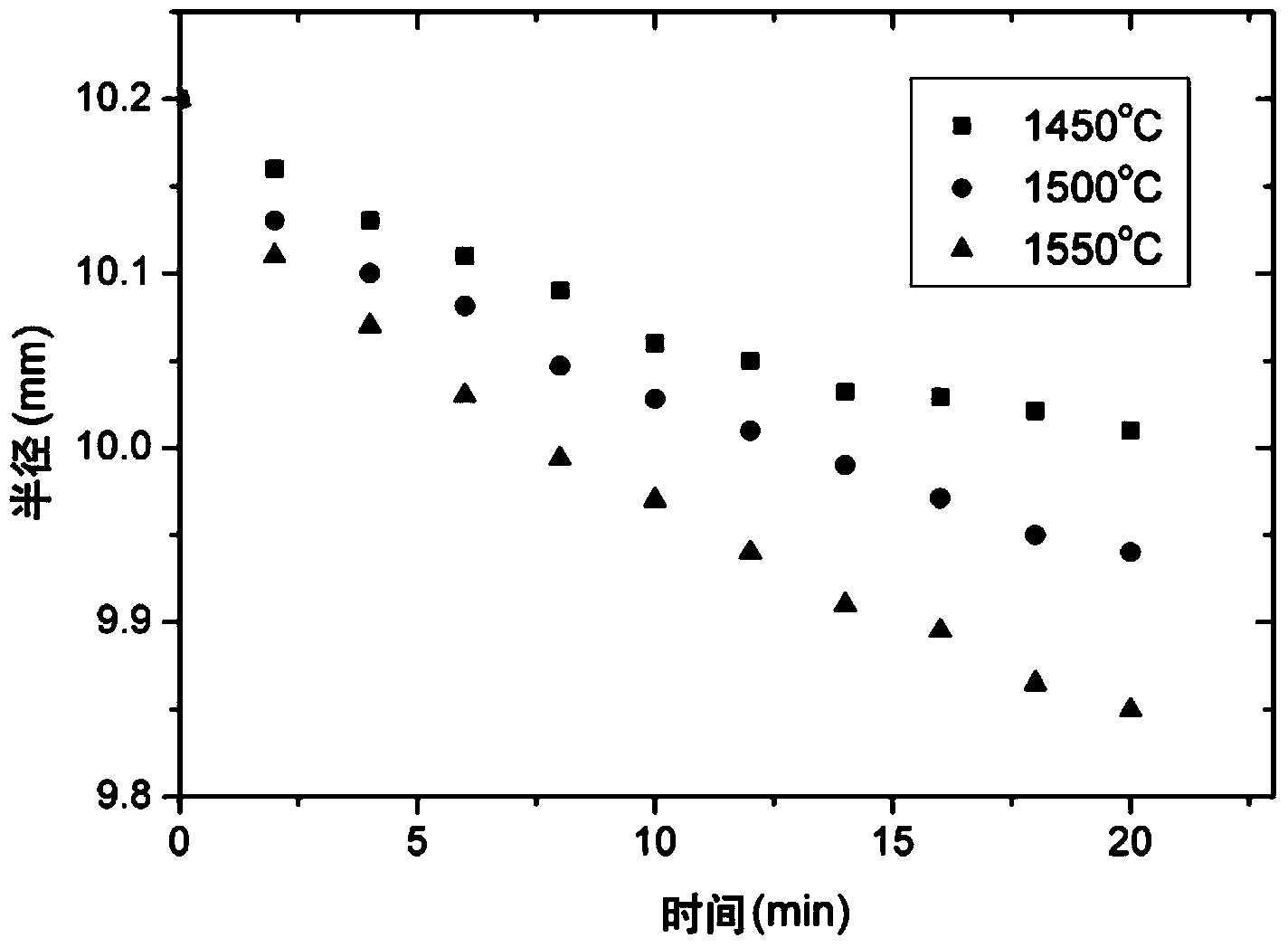

[0039] 3) Measure the viscosity at 1550°C, 1500°C and 1450°C under the corresponding slag composition with refractory measuring heads with different radii, and obtain the relationship between the viscosity value and the degree of erosion in Table 1. This is the reference viscosity point for the entire erosion measurement.

[0040] Table 1 Relationship between viscosity value and erosion ...

Embodiment 2

[0042] Example 2 The measurement temperature is 1550°C slag erosion to aluminum refractories

[0043] 1) Cut aluminum refractories into figure 2 Refractory measuring head of the shape shown, the chemical composition of the refractory is CaO:1.1%, SiO 2 :12.0%,Al 2 o 3 : 85.1%, FeO: 0.4%. see figure 1, the refractory measuring head 8 is in the shape of a cone connected under a cylinder, and the radius of the cylinder part is 10.2cm. There is a connecting part on the top of the cylinder. The shape of the top of the measuring head ┻┻ is used to connect the suspension wire 4, the refractory material wrapped outside and the measuring head.

[0044] 2) The chemical composition is CaO: 40%, SiO 2 :37%,Al 2 o 3 :13%,MgO:7%,TiO 2 Put into molybdenum crucible 9 after the slag of 3% is fully mixed, then put into the hearth heating zone of tubular heating furnace 6 and prepare to heat; Furnace tube 7 is passed into nitrogen, guarantees that crucible is not oxidized. The upper d...

Embodiment 3

[0049] Example 3 Measuring temperature is 1500 ℃ slag erosion to aluminum refractory material

[0050] 1) Make the aluminum refractory material into the directional measuring head of the required shape, and the radius of the cylindrical part is 10.2cm. The chemical composition of the refractory material is CaO: 1.1%, SiO 2 :12.0%,Al 2 o 3 :85.1%, FeO:0.4%;

[0051] 2) The chemical composition is CaO: 40%, SiO 2 :37%,Al 2 o 3 :13%,MgO:7%,TiO 2 : 3% of the slag is fully mixed and then put into a molybdenum crucible, and then put into the furnace heating zone to prepare for heating;

[0052] 3) Start furnace heating, heat up at 5°C / min, keep warm for 2 hours when it reaches 1600°C, make the slag composition fully uniform, and put the directional probe at the same time; then start to cool down at a rate of 5°C / min, after reaching 1500°C Keep warm for 0.5 hours. Then start the motor, rotate the directional probe, and start to measure the slag erosion resistance of the refr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com