A microfluidic three-dimensional flow delay control unit

A three-dimensional flow and time-delay control technology, which is applied in the direction of analyzing materials and instruments, can solve problems such as the inability to realize linkage multiple detections, inconsistent liquid head flow rates, and poor functions, so as to shorten the experimental period, reduce personnel costs, and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

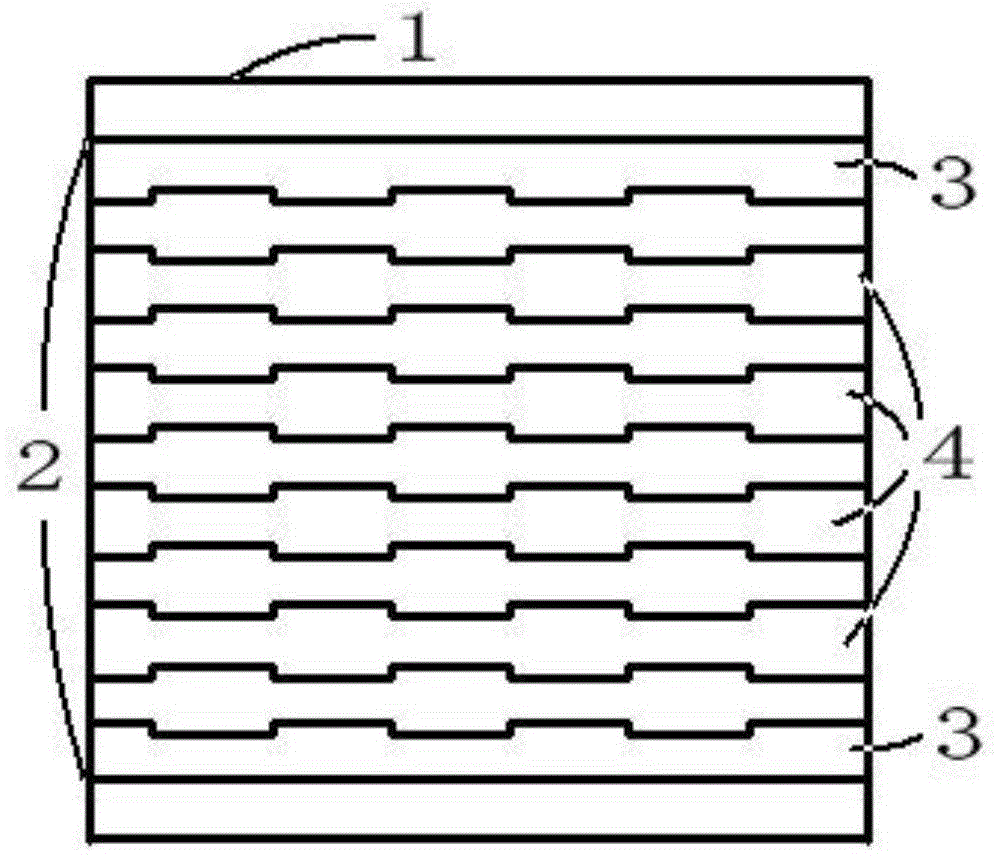

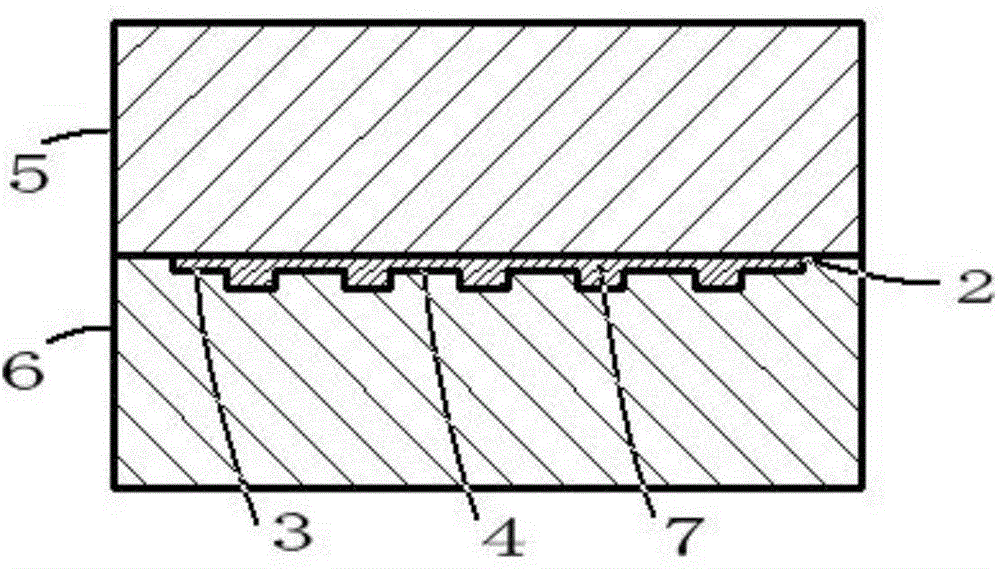

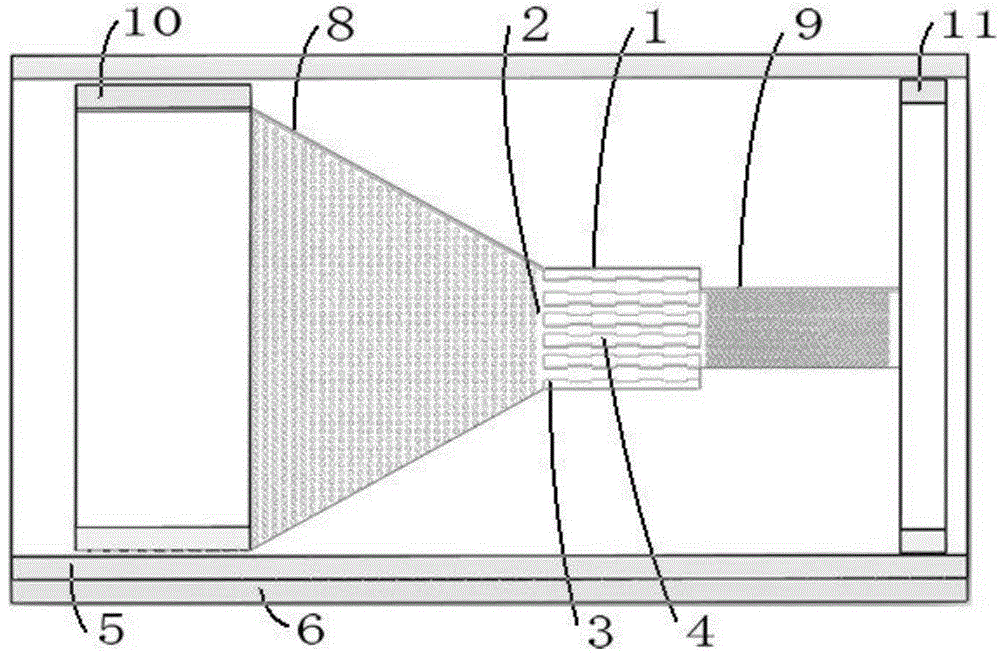

[0020] The microfluidic chip includes a mixing unit 8 , a three-dimensional flow delay control unit 1 , a detection unit 9 , a liquid storage pool 10 , and a waste liquid recovery pool 11 . The inlet of the three-dimensional flow delay control unit 1 is connected to the outlet of the mixing unit 8 , and the outlet of the three-dimensional flow delay control unit 1 is connected to the inlet of the detection unit 9 . The microstructures of the mixing unit 8 and the detection unit 9 are regularly distributed micro cylinder arrays, the diameter of the cylinders is 20 μm, the height of the cylinders is 10 μm, and the distance between the cylinders is 40 μm.

[0021] The microfluidic three-dimensional flow time-delay control unit 1 is composed of a channel 2 and tooth-shaped boss structures equally spaced on the channel. The height of the tooth-shaped boss structure is smaller than the depth of the channel 2, forming a three-dimensional structure; the channel 2 The depth is 20 μm, t...

Embodiment 2

[0026] The microfluidic chip includes a mixing unit 8 , a three-dimensional flow delay control unit 1 , a detection unit 9 , a liquid storage pool 10 , and a waste liquid recovery pool 11 . The inlet of the three-dimensional flow delay control unit 1 is connected to the outlet of the mixing unit 8 , and the outlet of the three-dimensional flow delay control unit 1 is connected to the inlet of the detection unit 9 . The microstructures of the mixing unit 8 and the detection unit 9 are regularly distributed micro cylinder arrays, the diameter of the cylinders is 200 μm, the height of the cylinders is 70 μm, and the distance between the cylinders is 400 μm.

[0027] The microfluidic three-dimensional flow time-delay control unit 1 is composed of a channel 2 and tooth-shaped boss structures equally spaced on the channel. The height of the tooth-shaped boss structure is smaller than the depth of the channel 2, forming a three-dimensional structure; the channel 2 The depth is 100 μm...

Embodiment 3

[0032] The microfluidic chip includes a mixing unit 8 , a three-dimensional flow delay control unit 1 , a detection unit 9 , a liquid storage pool 10 , and a waste liquid recovery pool 11 . The inlet of the three-dimensional flow delay control unit 1 is connected to the outlet of the mixing unit 8 , and the outlet of the three-dimensional flow delay control unit 1 is connected to the inlet of the detection unit 9 . The microstructures of the mixing unit 8 and the detection unit 9 are regularly distributed micro cylinder arrays, the diameter of the cylinders is 500 μm, the height of the cylinders is 150 μm, and the distance between the cylinders is 800 μm.

[0033] The microfluidic three-dimensional flow time-delay control unit 1 is composed of a channel 2 and tooth-shaped boss structures equally spaced on the channel. The height of the tooth-shaped boss structure is smaller than the depth of the channel 2, forming a three-dimensional structure; the channel 2 The depth is 200 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com