Electron beam emittance measuring equipment and measuring method

A technology of electron beam emission and measurement device, which is applied in the direction of measurement device, radiation measurement, X/γ/cosmic radiation measurement, etc., and can solve problems such as large influence of beam spot diameter measurement error, vacuum damage of accelerator pipeline, and increased work cycle. , to achieve the effect of improving vacuum sealing performance, improving stability and precision, and high stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

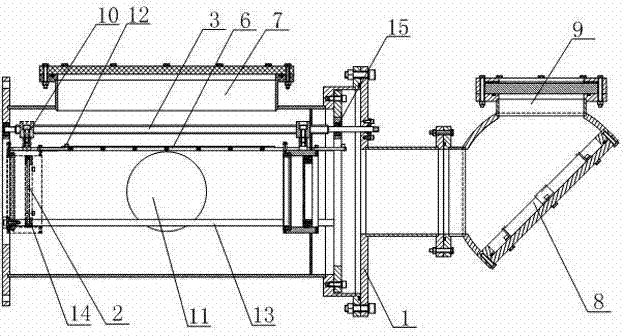

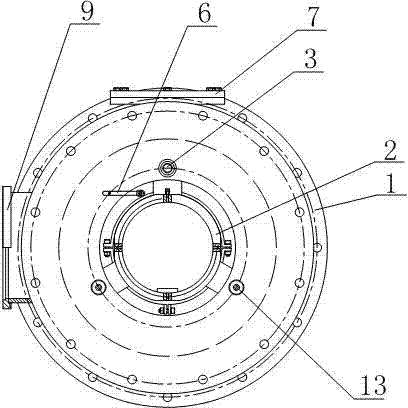

[0032] Such as Figures 2 to 3 As shown, an electron beam emissivity measuring device of the present invention includes a measurement target chamber 1, which is formed by surrounding a plurality of components, and is cylindrical in shape as a whole, and one end thereof is used as the injection end of the electron beam. Transparent glass is installed, and the other end is provided with two ring-shaped end faces with unequal diameters. In this section, a turning channel is connected through a flange, and a reflector 8 and a measuring window 9 are installed in the turning channel. The measuring window 9 is used to install a transparent quartz glass window, so that the luminescent image of the target can be sent out and taken by a camera placed on the side; a lead screw 3 is installed in the measurement target chamber 1, and the lead screw 3 is located above the axis of the measurement target chamber 1 One end of the lead screw 3 passes through the two ring-shaped end faces of une...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com