Rapid adjustment method of reflective concentric optical system

A technology of optical system and assembly method, which is applied in the direction of adopting optical devices, optics, optical components, etc., can solve the problems of complex process, high requirements for assembly environment, low efficiency and precision, etc., and achieve the improvement of assembly efficiency and intuitive performance and improve the efficiency of assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] The quick installation and adjustment method of the reflective concentric optical system of the present invention is realized by the following steps:

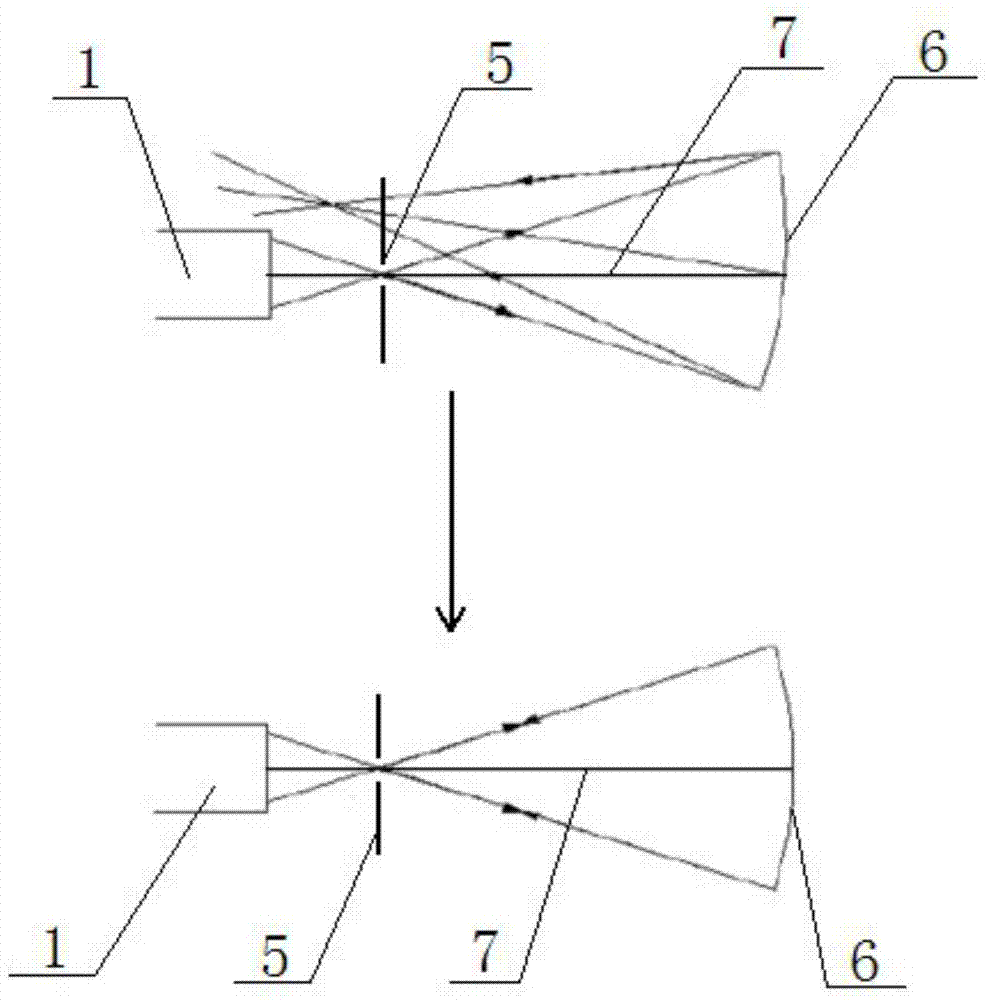

[0019] Step 1. Measure the axis 7 of the reflective concentric optical system

[0020] Such as figure 1 As shown, the autocollimated light of the autocollimator 1 is incident from the incident slit 5 through the reflective concentric optical system to the center of the detector 6 plane, and the line connecting the center of the incident slit 5 and the center of the detector 6 plane is the reflective concentric optical system. The axis 7 for the adjustment of the concentric optical system, through which the five degrees of freedom, three offsets and two angles of the reflective concentric optical system can be determined;

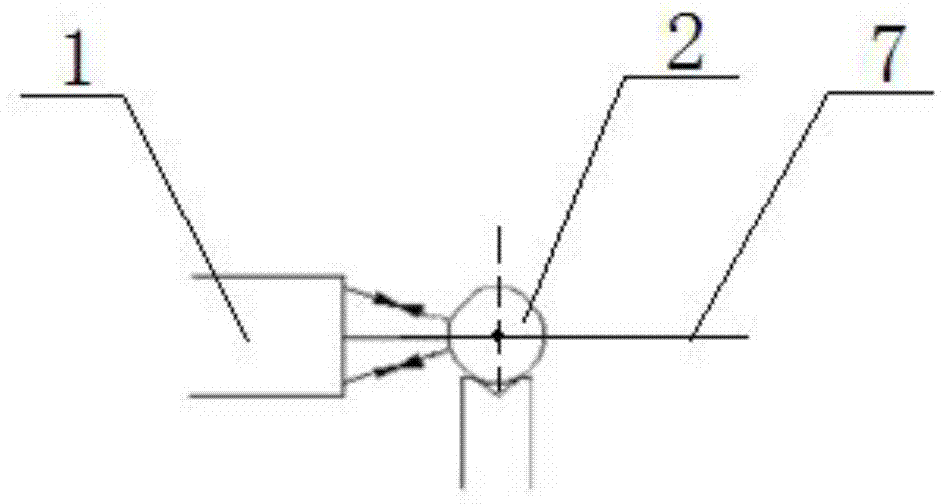

[0021] Step 2. Determine the position of the center of the sphere when the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com