A method of controlling phosphorus doping concentration by using pre-oxidation combined with low temperature-high temperature-low temperature variable temperature diffusion method

A phosphorus-doped, low-temperature technology, applied in the field of solar cells, can solve problems such as PN junction burn-through leakage, poor square resistance uniformity, and single temperature gradient setting method, and achieve improved conversion efficiency, good square resistance uniformity, and good PN The effect of junction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

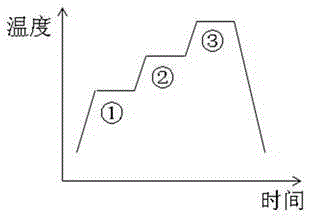

[0026] Such as image 3 As shown, taking polysilicon wafer as an example:

[0027] (1) Put the textured silicon wafer into the boat, and at a low temperature of 750°C, feed 2000 sccm / min oxygen and 15000 sccm / min nitrogen for pre-oxidation, and the oxidation time is 7 minutes;

[0028] (2) The temperature is controlled at 750°C, and 800 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 200 sccm / min of oxygen are fed for deposition and diffusion push junction for 20 minutes;

[0029] (3) Raise the temperature to 825°C, feed 900 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition, diffusion and pushing, and the time is 15 minutes;

[0030] (4) Cool down to 765°C, feed 900 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition, diffusion and push junction, and the time is 7 minutes;

[...

Embodiment 2

[0038] Such as image 3 As shown, taking polysilicon wafer as an example:

[0039] (1) Put the textured silicon wafer into the boat, and at a low temperature of 750°C, feed 2000 sccm / min oxygen and 15000 sccm / min nitrogen for pre-oxidation, and the oxidation time is 7 minutes;

[0040] (2) The temperature is controlled at 770°C, and 750 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 200 sccm / min of oxygen are fed for deposition and diffusion push junction for 20 minutes;

[0041] (3) Raise the temperature to 830°C, feed 800 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition, diffusion and push junction, and the time is 15 minutes;

[0042] (4) Cool down to 790°C, feed 800 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition, diffusion and push junction, and the time is 7 minutes...

Embodiment 3

[0045] Such as image 3 As shown, taking polysilicon wafer as an example:

[0046] (1) Put the textured silicon wafer into the boat, and at a low temperature of 750°C, feed 2000 sccm / min oxygen and 15000 sccm / min nitrogen for pre-oxidation, and the oxidation time is 7 minutes;

[0047] (2) Under the condition of temperature control at 750°C, 700 sccm / min of small nitrogen carrying phosphorus source, 16000 sccm / min of large nitrogen and 200 sccm / min of oxygen are fed for deposition and diffusion pushing for 25 minutes;

[0048] (3) Raise the temperature to 825°C, feed 800 sccm / min of small nitrogen carrying phosphorus source, 16000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition and diffusion push junction, and the time is 17 minutes;

[0049](4) Cool down to 765°C, feed 800 sccm / min of small nitrogen carrying phosphorus source, 16000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition, diffusion and push junction, and the time is 9 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com