Method for carrying out control over phosphorous doping concentration through combination of pre-oxidation mode and low temperature-high temperature-low temperature variable-temperature diffusion mode

A phosphorus-doped, low-temperature technology, applied in the field of solar cells, can solve problems such as the inability to obtain improved cell conversion efficiency, single temperature gradient setting method, and unessentially optimized PN junction characteristics, etc., to achieve good PN junction characteristics, good The uniformity of square resistance and the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

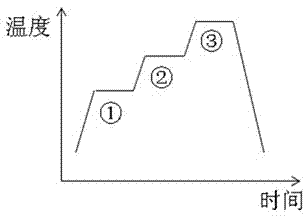

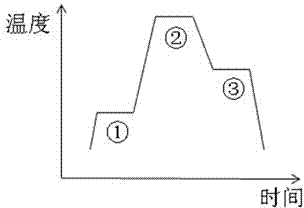

[0026] Such as image 3 As shown, taking polysilicon wafer as an example:

[0027] (1) Put the textured silicon wafer into the boat, and at a low temperature of 750°C, feed 2000 sccm / min oxygen and 15000 sccm / min nitrogen for pre-oxidation, and the oxidation time is 7 minutes;

[0028] (2) Under the condition of temperature control at 750°C, 800 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 200 sccm / min of oxygen are fed for deposition and diffusion pushing for 20 minutes;

[0029] (3) Raise the temperature to 825°C, feed 900 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition, diffusion and pushing, and the time is 15 minutes;

[0030] (4) Cool down to 765 °C, feed 900 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition, diffusion and pushing, and the time is 7 minutes;

[00...

Embodiment 2

[0037] Such as image 3 As shown, taking polysilicon wafer as an example:

[0038] (1) Put the textured silicon wafer into the boat, and at a low temperature of 750°C, feed 2000 sccm / min oxygen and 15000 sccm / min nitrogen for pre-oxidation, and the oxidation time is 7 minutes;

[0039] (2) Under the condition of temperature control at 770°C, 750 sccm / min of small nitrogen carrying phosphorus source, 15000 sccm / min of large nitrogen and 200 sccm / min of oxygen are fed for deposition and diffusion pushing for 20 minutes;

[0040] (3) Raise the temperature to 830°C, feed 800sccm / min small nitrogen carrying phosphorus source, 15000sccm / min large nitrogen and 300sccm / min oxygen for deposition, diffusion and push junction, and the time is 15min;

[0041] (4) Cool down to 790 ℃, feed 800sccm / min of small nitrogen carrying phosphorus source, 15000sccm / min of large nitrogen and 300sccm / min of oxygen to deposit, diffuse and push the junction, and the time is 7min;

[0042] (5) Carry ou...

Embodiment 3

[0044] Such as image 3 As shown, taking polysilicon wafer as an example:

[0045] (1) Put the textured silicon wafer into the boat, and at a low temperature of 750°C, feed 2000 sccm / min oxygen and 15000 sccm / min nitrogen for pre-oxidation, and the oxidation time is 7 minutes;

[0046] (2) Under the condition of temperature control at 750°C, 700 sccm / min of small nitrogen carrying phosphorus source, 16000 sccm / min of large nitrogen and 200 sccm / min of oxygen are fed for deposition and diffusion pushing for 25 minutes;

[0047] (3) Raise the temperature to 825°C, feed 800 sccm / min of small nitrogen carrying phosphorus source, 16000 sccm / min of large nitrogen and 300 sccm / min of oxygen for deposition, diffusion and pushing, and the time is 17 minutes;

[0048](4) Cool down to 765 ℃, feed 800sccm / min of small nitrogen carrying phosphorus source, 16000sccm / min of large nitrogen and 300sccm / min of oxygen for deposition, diffusion and pushing, and the time is 9 minutes;

[0049] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com