Lead acid storage battery plate humidifier

A lead-acid battery and humidification device technology, applied in the direction of lead-acid battery electrodes, air humidification system, heating method, etc., can solve the problems of lead paste water loss, ambient temperature rise, long residence time, etc., to reduce product cost, Prevent cracking and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

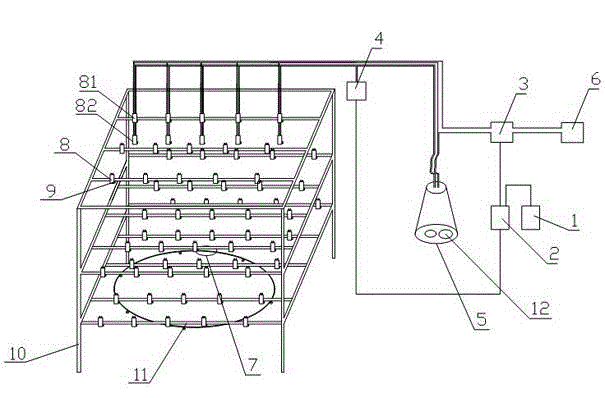

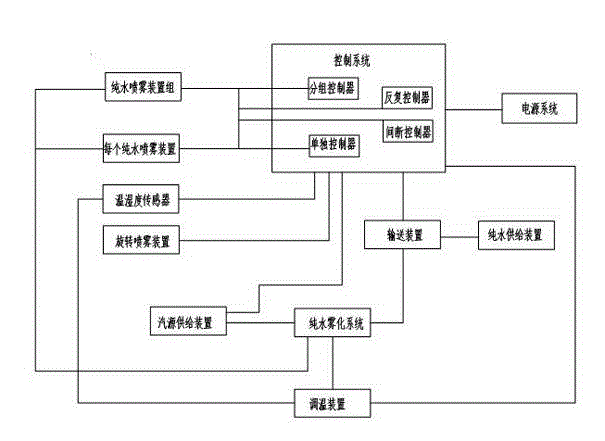

[0024] exist figure 1 In the shown embodiment, a kind of lead-acid storage battery pole plate humidifying device comprises elastic support pole plate support 10, and the pole plate support 10 is provided with multi-layer elastic drying plate rack 11, also comprises power supply system 1, control system 2, Conveying device 3, air source supply device 4, pure water atomization system 5 and pure water supply device 6, a rotary sprayer 7 is arranged on the pole plate support 10, and the rotary sprayer 7 is arranged on the rotary spray track, and the rotary spray track is circular track, the rotating spray track is provided with a universal pulley, the pure water supply device 6 is connected to the conveying device 3, the conveying device 3 is respectively connected to the pure water atomization system 5 and the control system 2, and the air source supply device 4 is respectively connected to the pure water atomization The system 5 is connected to the control system 2, the rotary s...

Embodiment 2

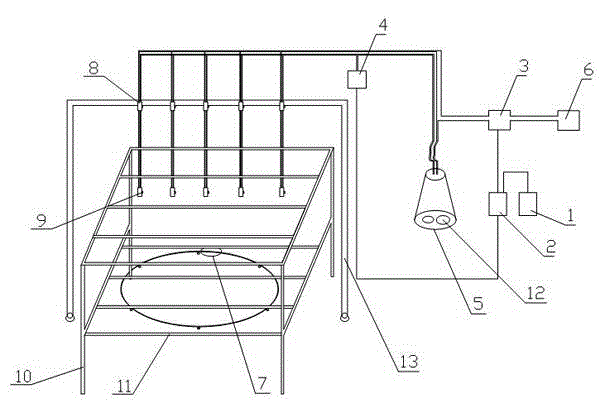

[0028] exist image 3 In the shown embodiment, a kind of lead-acid storage battery pole plate humidifying device comprises elastic support pole plate support 10, and the pole plate support 10 is provided with multi-layer elastic drying plate rack 11, also comprises power supply system 1, control system 2, Conveying device 3, air source supply device 4, pure water atomization system 5 and pure water supply device 6, a rotary sprayer 7 is arranged on the pole plate support 10, and the rotary sprayer 7 is arranged on the rotary spray track, and the rotary spray track is circular track, the rotating spray track is provided with a universal pulley, the pure water supply device 6 is connected to the conveying device 3, the conveying device 3 is respectively connected to the pure water atomization system 5 and the control system 2, and the air source supply device 4 is respectively connected to the pure water atomization The system 5 is connected to the control system 2, the rotary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com