Pre-twisted composite phase-to-phase spacer

A technology of interphase spacer bars and spacer bars, which is applied in the field of electric devices, can solve problems such as broken wires, vertical lift of wires, damage to guard rails and iron towers, and achieve the effect of preventing pollution flashover accidents, short circuit problems, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

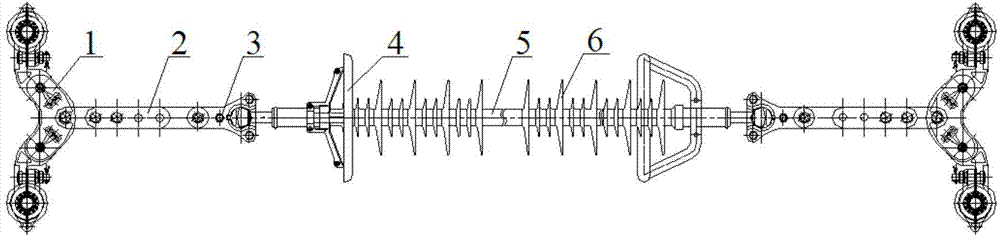

[0010] See figure 1 , A pre-twisted composite interphase spacer, comprising a composite interphase spacer body and left and right pre-twisted spacer rods 1. The two ends of the composite interphase spacer body and the rear end of the left and right pre-twisted spacer rods 1 The buffer 3 and the adjusting plate 2 are respectively connected in turn. The body of the composite interphase spacer includes a core rod 5, an umbrella skirt 6 and an equalizing ring 4, and the umbrella skirt 6 and equalizing ring 4 are respectively fixedly installed on the core rod 5. .

[0011] In the present invention, there are multiple umbrella skirts 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com