Method and device for controlling an internal combustion engine

A technology for control devices and internal combustion engines, applied in fuel injection devices, internal combustion piston engines, electrical control, etc., can solve the problems of expensive and costly, achieve the effect of improving starting ability and simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

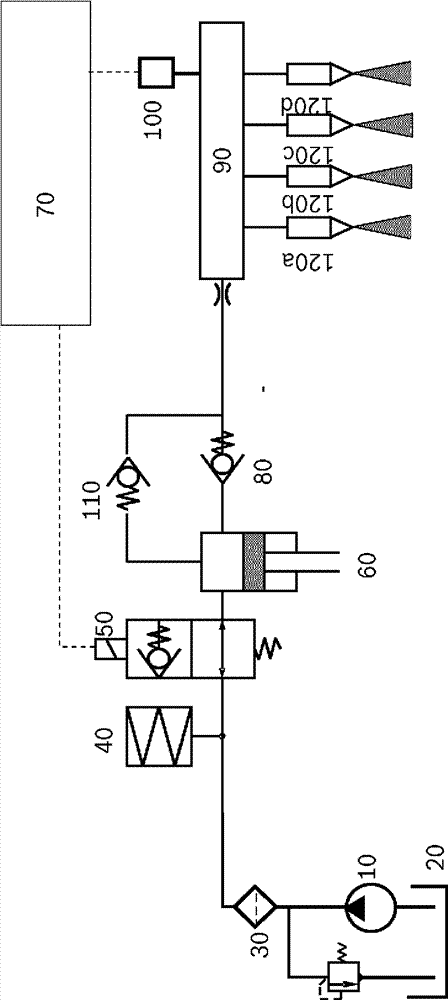

[0027] figure 1 An injection system is shown. Fuel is delivered by an electronic fuel pump 10 from a fuel tank 20 via a fuel filter 30 , a low-pressure buffer 40 and a flow control valve 50 to a high-pressure pump. The electronic fuel pump 10, the filter 30, the low pressure buffer 40 and the flow control valve 50 form the low pressure side of the injection system. The electronic fuel pump generates a pressure of several Bars, the low-pressure buffer 40 buffers pressure pulsations in a fuel line in which fuel is delivered, and the flow control valve 50 is regulated by a control device and / or The device 70 is controlled in such a way that it doses the desired or required fuel quantity. The high-pressure pump 60 delivers fuel via a check valve 80 to a fuel rail 90 . The high-pressure pump 60 generates pressures of up to several 100 Bar in this case. The pressure in the high-pressure rail 90 is detected by a rail pressure sensor 100 and transmitted back to the control and / or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com