Pipeline cleaning robot and control method

A pipeline cleaning and robot technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as difficulty in obtaining real-time information, inability to realize point movement, and large environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

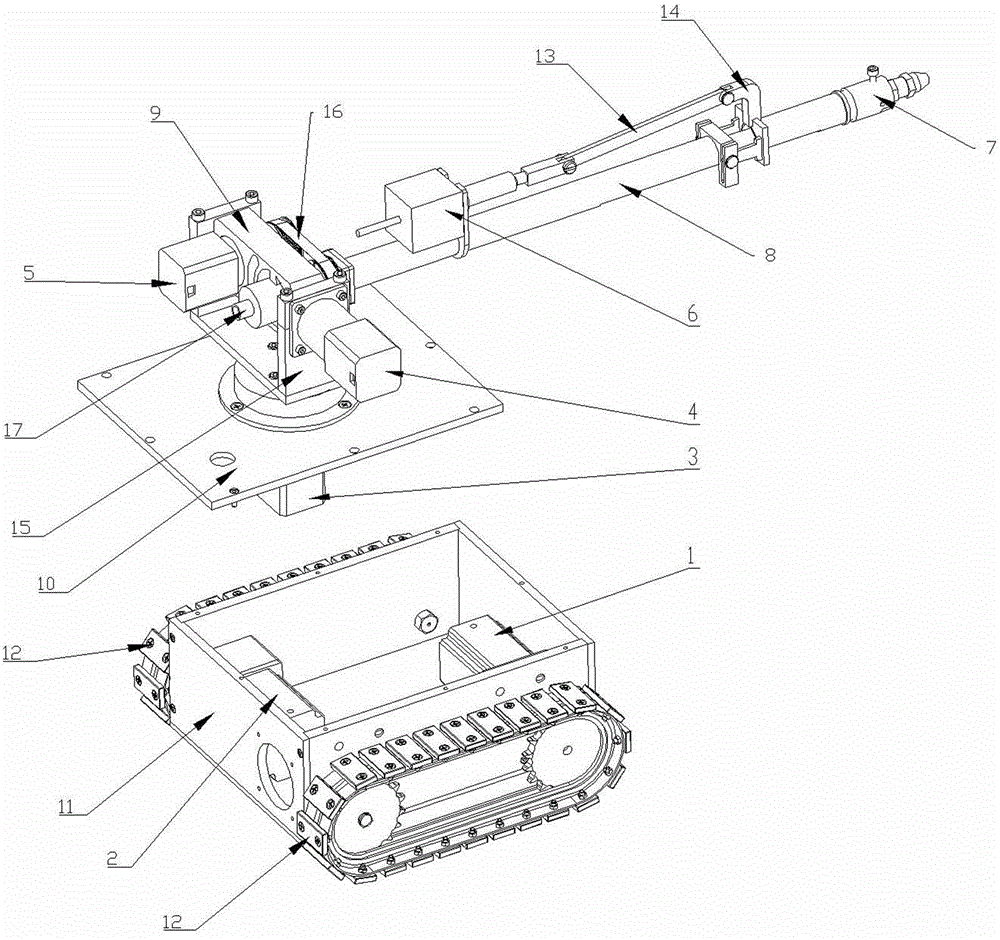

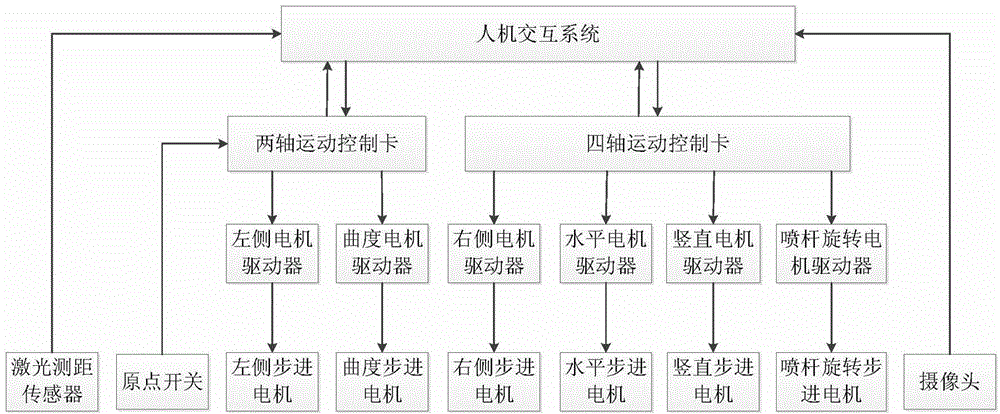

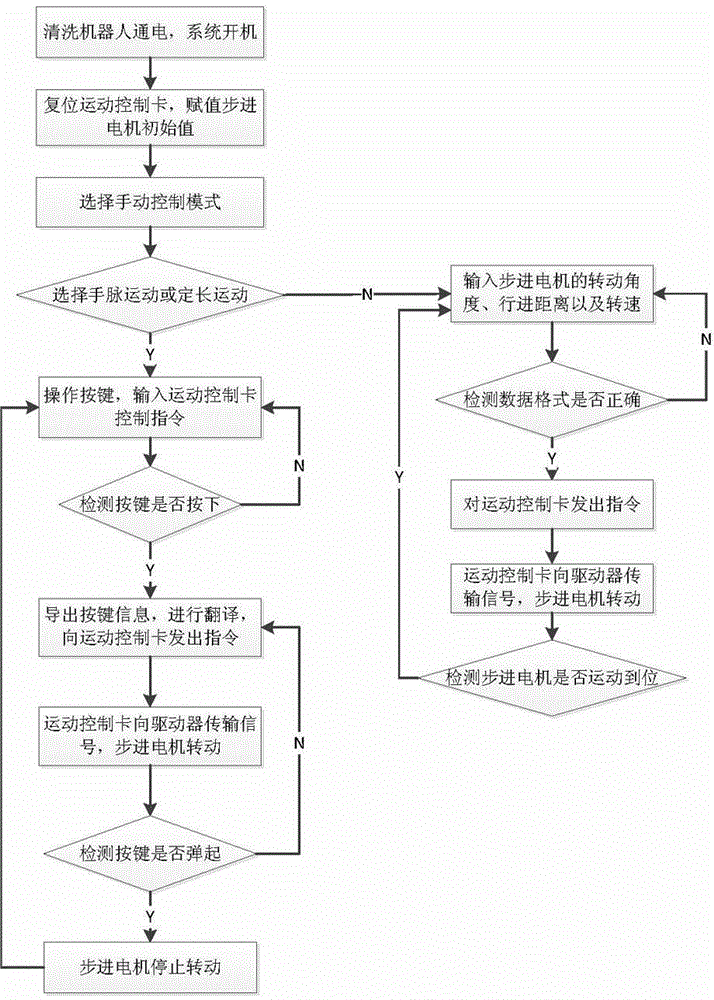

[0069] The pipe cleaning robot of the present invention includes: a base 11, a horizontal rotating disk 10, a spray bar rotating seat 9, a spray bar 8, a spray head 7, a curvature stepping motor 6, a spray bar rotating stepping motor 5, and a vertical stepping motor 4 , a horizontal stepping motor 3, a left stepping motor 2, a right stepping motor 1 and a control system.

[0070] Such as figure 1 , 2 Shown, base, its both sides outside are provided with crawler belt rotating device, and base is provided with left and right side stepping motor, and left and right side stepping motor is driven by gear and crawler belt 12 transmissions, drives robot to move back and forth. The horizontal rotating disk 10 is located on the base 11, on which the spray boom rotating seat 9 is installed, and the horizontal stepping motor 3 is installed below it, and the output shaft of the horizontal stepping motor 3 passes through the horizontal rotating disk 10 and the spraying boom rotating seat....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com