Ladle bottom structure capable of reducing continuous casting ladle cast residues

A technology of overcasting and continuous casting, which is applied in casting equipment, casting molten material containers, metal processing equipment, etc., and can solve the problems affecting the yield of molten steel and large casting allowance, so as to achieve less difficulty in masonry and reduce large ladle The effect of simple structure of casting residue and bottom cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

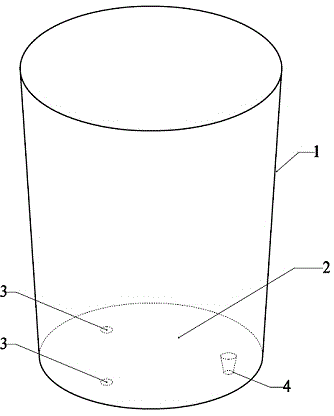

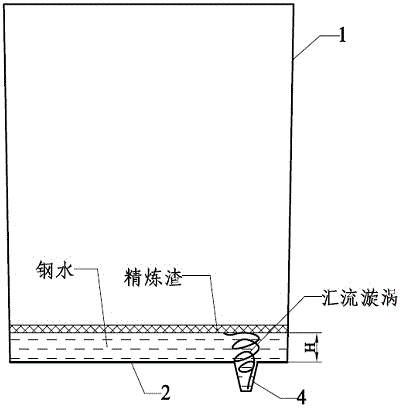

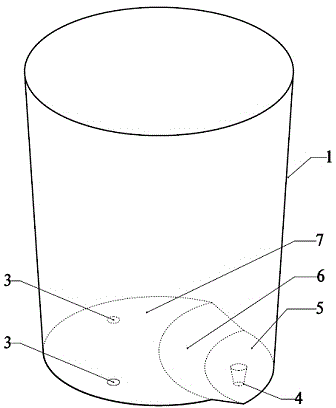

[0022] Example 1 : see image 3 , a clad bottom structure for reducing continuous casting ladle casting residue, the clad bottom and clad wall 1 together form a ladle inner cavity, the clad bottom structure includes a first plane 5, a second plane 7 and a transitional curved surface 6, The first plane 5 is provided with a large bag outlet 4, the second plane 7 is provided with a ventilating brick 3, the second plane 7 is higher than the first plane 5, and the transition curved surface 6 is provided on the first plane 5 and the second plane 7, the transition curved surface 6 connects the first plane 5 and the second plane 7. The transition between the first plane 5 and the second plane 7 is gentle, which ensures the circulation of molten steel in low-lying areas during argon blowing, avoids the formation of dead zones, and prevents the molten steel from being partially overcooled and resulting in freezing of the outlet.

Embodiment 2

[0023] Example 2 : see image 3 , as an improvement of the present invention, the first plane 5 is parallel to the second plane 7 . The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0024] Example 3 : see image 3 , as an improvement of the present invention, the first plane 5 is a small area enclosed by two inferior arcs, in order to reduce the ladle casting residue to a greater extent, and its center is the ladle outlet 4 . The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com