Automatic enveloping, jar mounting and welding device and method thereof

A welding equipment and welding method technology, which is applied in the field of automatic coating and slotting welding equipment, can solve the problems of low degree of automation, high labor intensity, affecting battery performance, etc., and achieve the goal of improving the degree of automation, improving work efficiency, and saving time and waiting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

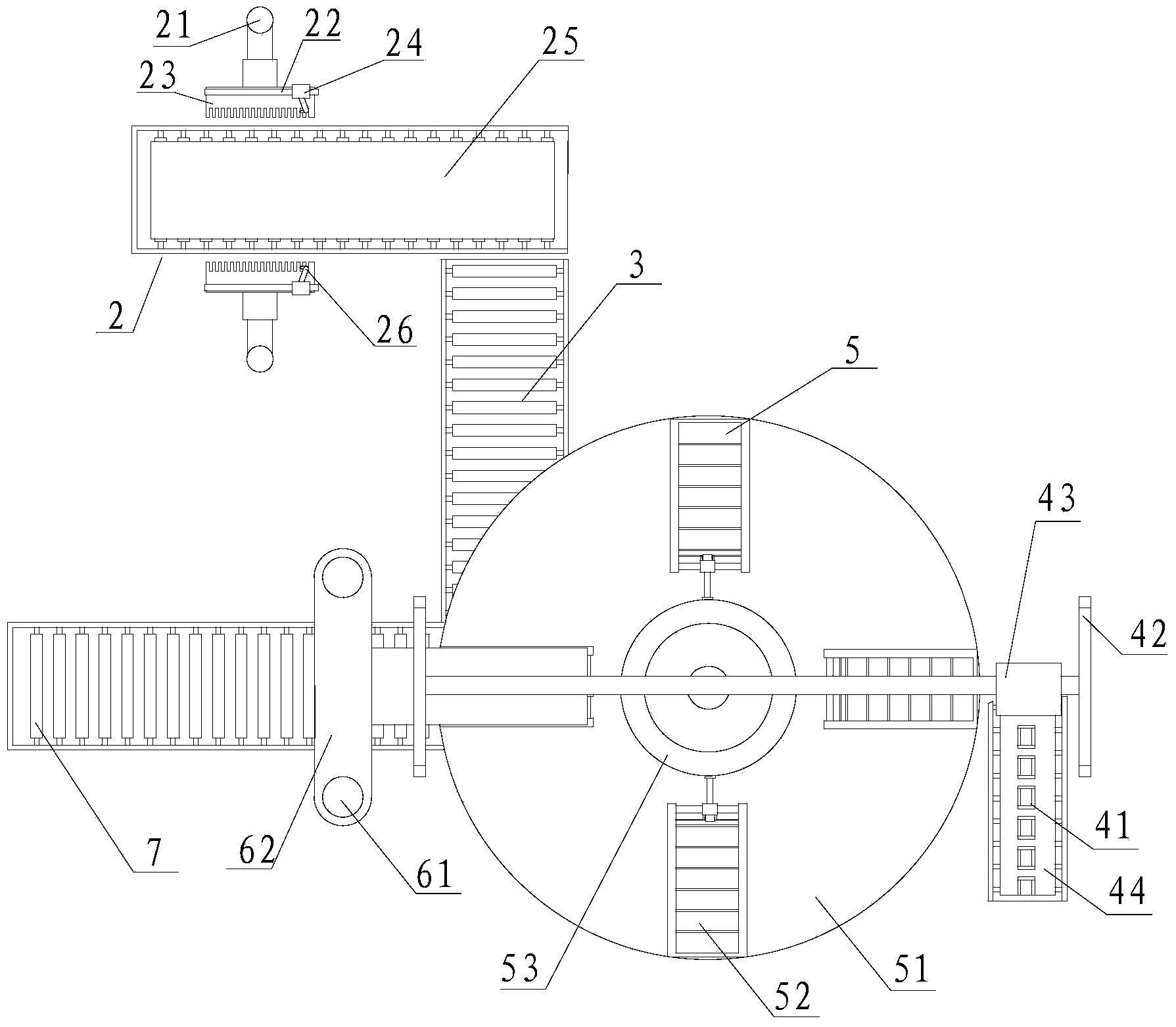

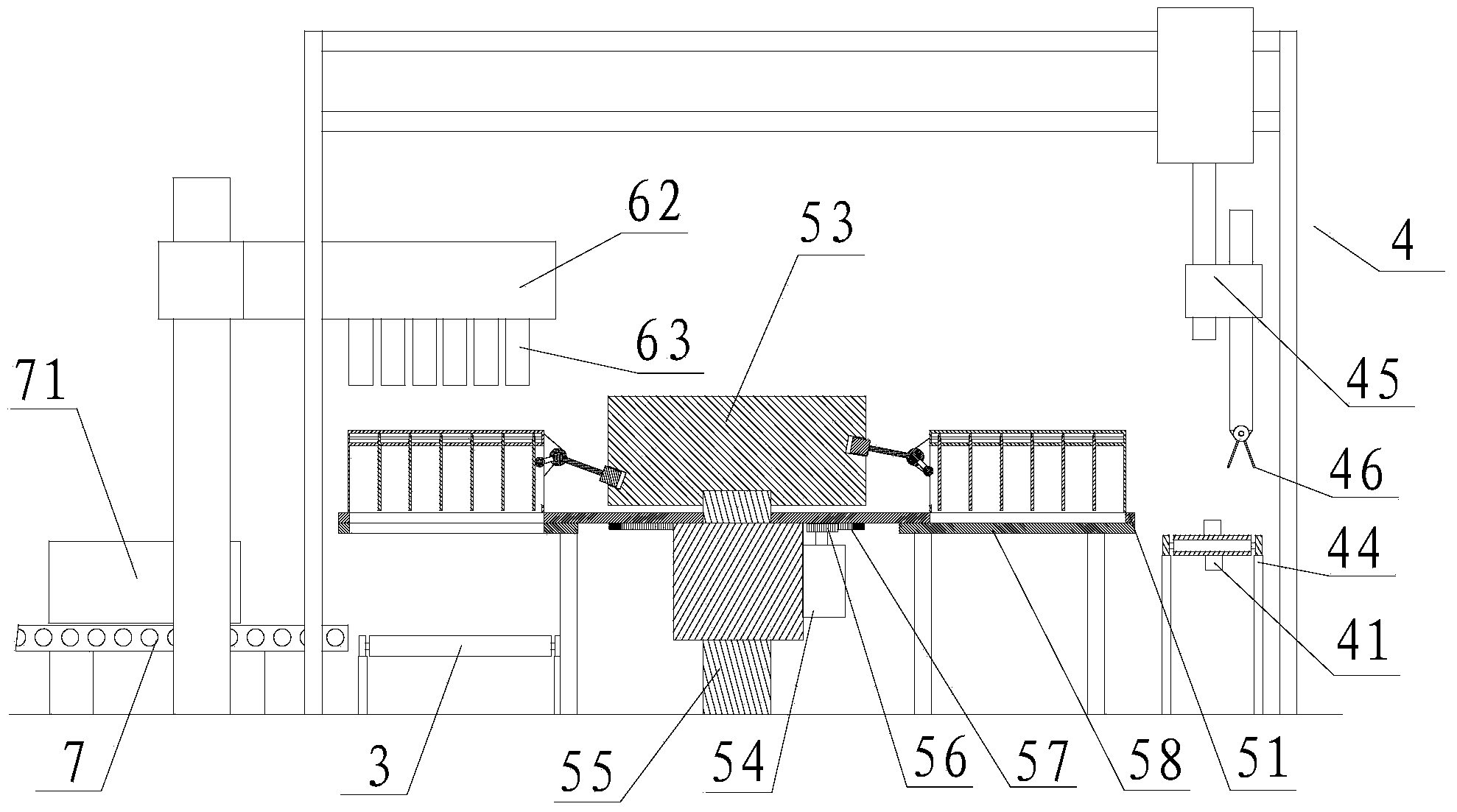

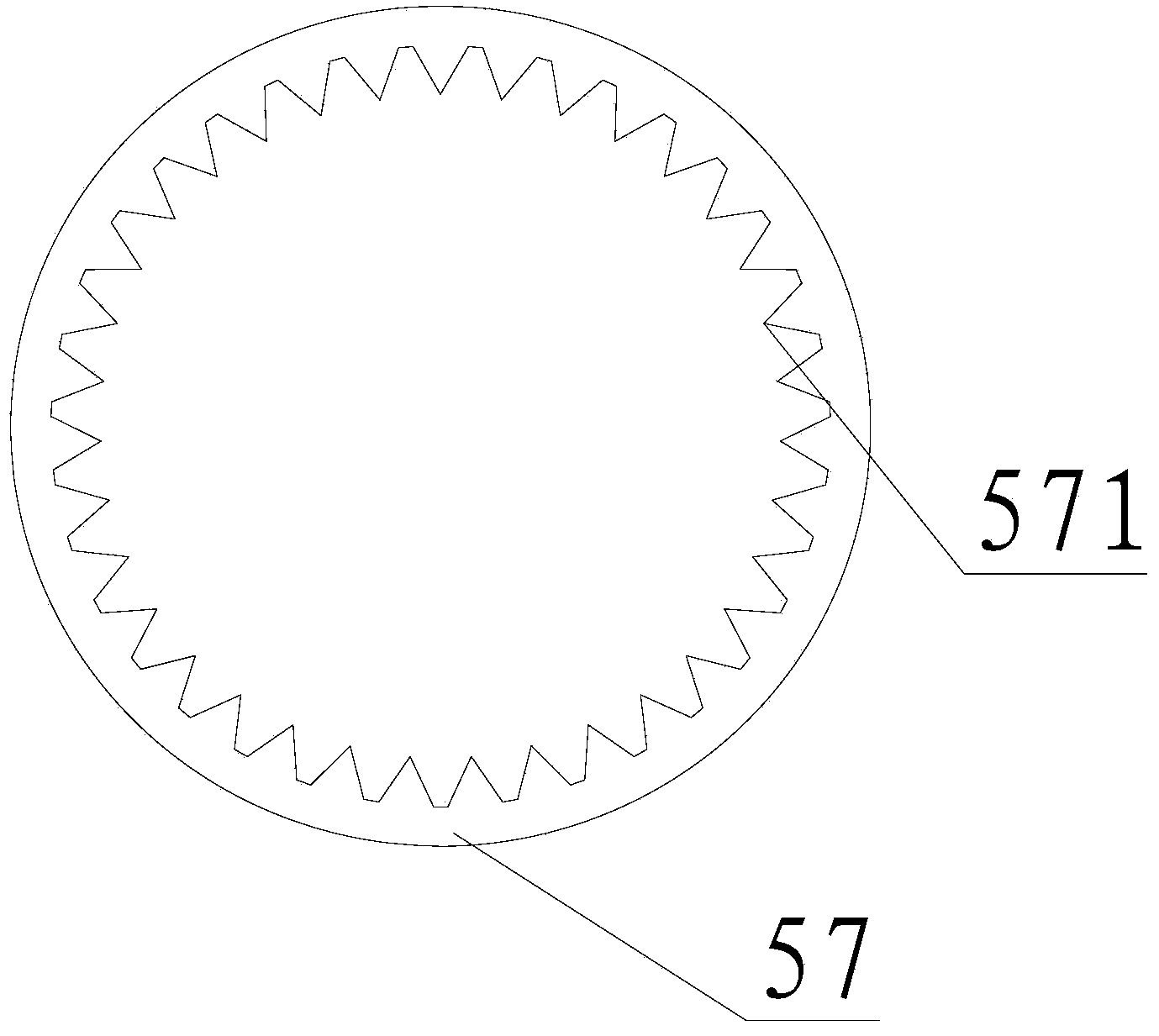

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a kind of automatic coating tank welding equipment of the present invention, comprises welding line 2, battery tank output conveyor belt 3, tank coating auxiliary mechanism 4, turntable mechanism 5 and battery tank loading mechanism 6, and described battery tank loading mechanism 6 is installed on One side of the turntable mechanism 5, the turntable mechanism 5 is installed with the trough coating auxiliary mechanism 4, and the trough coating auxiliary mechanism 4 includes a coating groove 41, a manipulator support 42, a transverse motor 43, a cluster conveyor belt 44, Vertical motor 45 and gripper 46, horizontal motor 43 is installed on the described manipulator support 42, and vertical motor 45 is installed on the bottom of horizontal motor 43, and gripper 46 is installed on the bottom of described vertical motor 45, is installed on the described cluster conveyer belt 44 There are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com